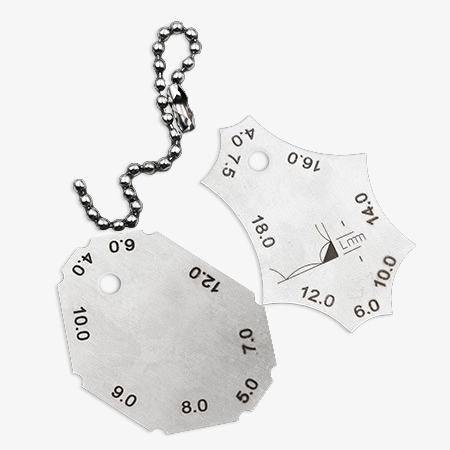

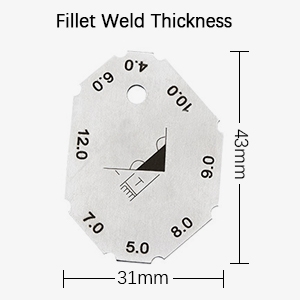

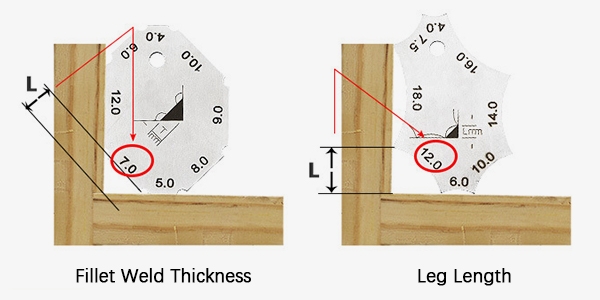

This pocket-sized right-angle weld gauge is compact enough to attach seamlessly to a keychain for easy portability. Featuring laser-engraved markings, it ensures clear readings even in bright light or oily environments. The welding gauge accurately measures critical parameters, including weld leg length, throat size, and permissible convexity. The dual-sided printed design enhances usability, allowing quick switching between measurement surfaces without the need to flip the tool, greatly improving on-site operational efficiency.

Ergonomic Design for Long-Lasting Precision

- Detachable Structure: The right-angle weld gauge allows for quick disassembly, making cleaning and maintenance easier. The grip area is ergonomically shaped to fit the curvature of the palm, ensuring comfort even during long periods of use and minimizing hand fatigue.

- Thick Forging Process: The surface of the weld gauge undergoes hard anodizing, with scale line depth reaching 0.2mm, making it five times more wear-resistant than traditional printing methods. This enhances clarity for precise readings.

Stainless Steel Durability for Harsh Working Conditions

- Stainless Steel Construction: Made from high-quality stainless steel, the right-angle weld gauge offers exceptional hardness and superior wear resistance. Its corrosion-resistant surface ensures that the gauge maintains a clean, polished appearance even in humid or salt-laden environments.

- Fine Polishing Process: The refined polishing process enhances the overall aesthetic of the weld gauge, while the laser-engraved scale lines are deeply processed for a more three-dimensional appearance.

Applications

Weld gauges are widely used in various industries. In boiler manufacturing, they measure weld reinforcement, width, misalignment, and undercut depth to meet pressure part standards. In shipbuilding, they check fillet weld size, leg height, and assembly gaps to ensure hull strength. In oil pipelines, welding gauges assess groove angles and gap sizes to prevent welding defects and leaks. In industrial construction—such as bridges and pressure vessels—they provide accurate weld dimension data for process evaluation and quality control.

Shipbuilding

Oil Pipelines

Industrial Construction

Boiler Manufacturing

| Model | SISCO-WG-RA |

| Material | Stainless Steel |

| Accuracy | ±0.05mm |

| Scale Process | Laser Engraving |

| Packaging | Plastic Bag |

| Net Weight | 15g |

| Fillet Weld Measurement Range | 4.0/5.0/6.0/7.0/8.0/9.0/10.0/12.0 mm |

| Leg Length Measurement Range | 4.0/6.0/7.5/10.0/12.0/14.0/16.0/18.0 mm |

Details

Q1: How accurate is the SISCO right-angle weld gauge?

A1: The SISCO right-angle weld gauge offers exceptional accuracy with a tolerance of ±0.05mm. This high precision makes it perfect for ensuring precise measurements of critical weld parameters such as fillet weld size, leg length, and throat dimensions. Whether you're working with small or large welds, the weld gauge provides reliable readings to meet the highest industry standards.

Q2: What materials is the right-angle weld gauge made of?

A2: The welding gauge is crafted from high-quality stainless steel, which is known for its excellent strength, durability, and resistance to corrosion. This robust material ensures that the gauge can withstand tough work environments, including exposure to moisture, oil, and other harsh conditions, without compromising on performance. Its stainless steel construction also ensures long-lasting precision.

Q3: Can I use the right-angle weld gauge for all welding applications?

A3: Yes, the right-angle weld fillet gauge is designed for a wide range of welding applications. It can be used to measure fillet weld dimensions, throat size, leg length, and other critical parameters in industries like shipbuilding, pressure vessel construction, boiler manufacturing, and structural welding.

Tips: How do I maintain my weld gauge to ensure long-term accuracy?

To maintain the gauge in top condition and ensure it continues to provide precise measurements, follow these maintenance tips:

- Keep it clean: After use, wipe the gauge with a soft cloth to remove any debris, grease, or welding residue. This helps preserve the laser-engraved markings and prevents buildup that could affect readings.

- Store properly: Always store the weld gauge in a dry place, away from direct sunlight or extreme temperatures, to prevent any potential distortion of the material.

- Check regularly: Periodically inspect the gauge for signs of wear or damage, especially if it's used in heavy-duty conditions. Ensure the markings are still legible, and the tool remains free of corrosion or rust.

Following these steps will help prolong the life of the right-angle weld gauge and ensure it maintains its accuracy over time.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.