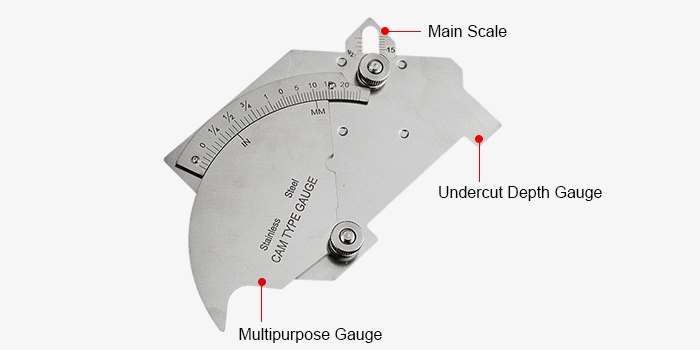

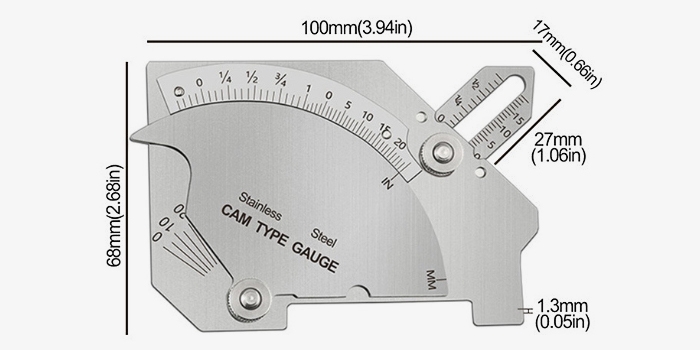

This dual-scale welding gauge features inch (IN) markings on the left and millimeter (MM) markings on the right to meet various measurement requirements. It helps welders precisely measure bevel angles, weld width, reinforcement height, and weld gaps. Made of durable stainless steel, the cam gauge is resistant to bending or warping, ensuring reliable, accurate measurements. Clear, finely etched laser markings make this weld fillet gauge ideal for quality control in diverse welding environments.

Premium Stainless Steel, Durable and Reliable

- Thickened Forged Construction: Crafted from high-strength stainless steel, this weld gauge offers a robust structure that resists deformation, wear, and impact, ideal for daily industrial use.

- Corrosion-Resistant Finish: Built to withstand harsh environments including moisture, chemicals, and salt spray, ensuring long-term accuracy and stability for all welding inspection tasks.

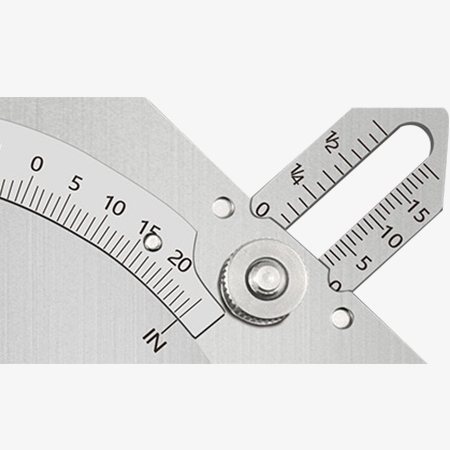

Laser-Etched Dual Scale, Clear and Accurate

- High-Contrast Laser Markings: Advanced laser-etching of the fillet gauge ensures finely detailed, easy-to-read scales that reduce human error, even in low-light conditions.

- Dual Metric & Imperial Units: With inch and millimeter scales on both sides, this weld cam gauge supports global measurement standards and simplifies weld size inspection across different regions.

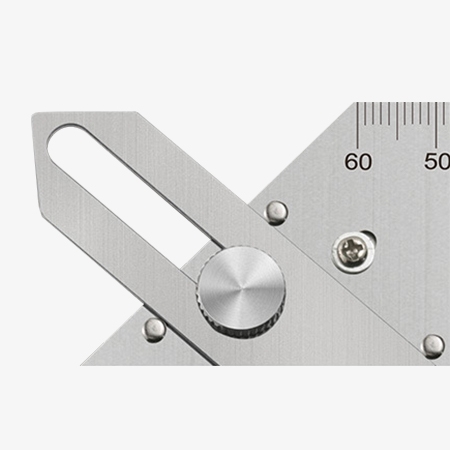

Oversized Adjusting Nut, Flexible and User-Friendly

- Tool-Free Adjustment: The enlarged adjusting nut allows for fast, manual adjustment of gauge length and angle. No extra tools needed, making on-site calibration quick and easy.

- Wide Measurement Range: Adjustable design accommodates various weld sizes and geometries, making the fillet weld gauge suitable for inspecting complex welding joints in multiple applications.

Applications

Weld gauges are widely used in various industries. In boiler manufacturing, they measure weld reinforcement, width, misalignment, and undercut depth to meet pressure part standards. In shipbuilding, they check fillet weld size, leg height, and assembly gaps to ensure hull strength. In oil pipelines, welding gauges assess groove angles and gap sizes to prevent welding defects and leaks. In industrial construction—such as bridges and pressure vessels—they provide accurate weld dimension data for process evaluation and quality control.

Shipbuilding

Oil Pipelines

Industrial Construction

Boiler Manufacturing

| Model | SISCO-WG-MG-8 | ||

| Material | Stainless Steel | ||

| Packaging | Leather Case | ||

| Weight | Net: 120g / Gross: 145g | ||

| Unit System | Left scale in Inches (IN), Right scale in Millimeters (MM) | ||

| Applications | Measures bevel angle, weld height, weld width, root gap; suitable for boilers, bridges, shipbuilding, and pressure vessels | ||

| Measurement Parameters | |||

| Measurement Item | Measuring Range | Graduation | Permissible Deviation |

| Weld Height | 0–25mm (0–1") | 1mm (1/16") | ±0.5mm |

| Weld Size | 0–25mm (0–1") | 1mm (1/16") | ±0.5mm |

| Misalignment (Hi-Lo) | 0–25mm (0–1") | 1mm (1/16") | ±0.05mm |

| Undercut Depth | 0–2mm (0–1/8") | 1mm (1/16") | ±0.5mm |

| Fillet Weld Leg Size | 0–25mm (0–3/4") | 1mm (1/16") | ±0.5mm |

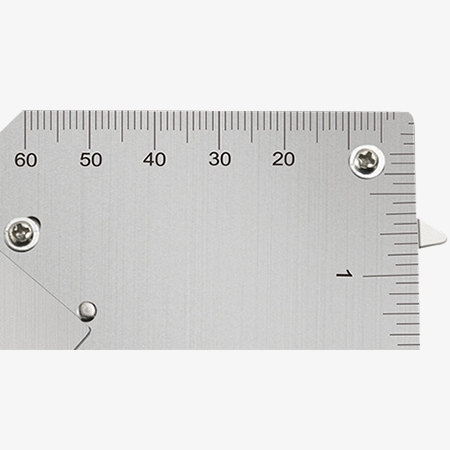

| Bevel Angle | 0–60° | 5° | ±1° |

| Linear Length | 0–60mm (0–2") | 1mm (1/16") | ±0.5mm |

| 45° Angle Tolerance | / | / | ±1° |

Details

Q1: What types of measurements can the cam-type weld gauge perform?

A1: The cam gauge is designed to accurately measure multiple welding parameters, including bevel angle, weld reinforcement height, weld width, and root gap. It’s a versatile tool for weld inspection across industries like shipbuilding, boiler manufacturing, and pressure vessel fabrication.

Q2: Is this weld gauge compatible with both metric and imperial units?

A2: Yes, this welding gauge features a dual scale—inch (IN) markings on the left and millimeter (MM) markings on the right, making it suitable for both metric and imperial measurement standards. It’s ideal for global welding projects with varied unit requirements.

Q3: How durable is the stainless steel cam-type gauge in industrial environments?

A3: Made from thickened, forged stainless steel, this fillet weld gauge is highly resistant to corrosion, bending, and surface wear. It maintains measurement accuracy even in harsh, humid, or chemically exposed environments.

Tips: How to get the most accurate readings with your weld gauge?

To ensure accurate weld measurements, always place the cam-type gauge firmly against the weld surface without gaps or tilts. Use the oversized adjustment nut to align the scale precisely, and read the laser-etched markings under direct light when possible. Keeping the gauge clean and free from debris or welding spatter will also improve reading clarity and prolong the tool’s lifespan.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.