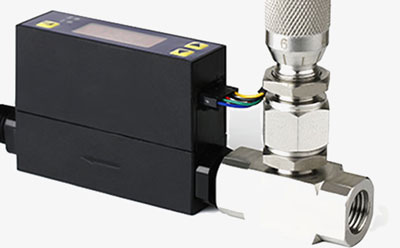

Gas mass flow meter designed for low flow rates (0-2/ 5/ 50L/min) in gas lines with diameters of 3mm and 8mm, high stability, no temperature compensation, flexible output through the communication interface, mass flow meters are widely used in environmental monitoring, equipment ventilation device testing and medical equipment such as ventilators.

No temperature compensation required

- Sensing chip using thermal mass flow measurement, to ensure the flowmeter's high precision metering.

- Gas mass flow meter full range of high stability, high accuracy, and excellent repeatability.

Flexible output

- Active upload via communication interface Data.

- The gas mass flow meter allows field configuration of the flow meter parameters with the keypad.

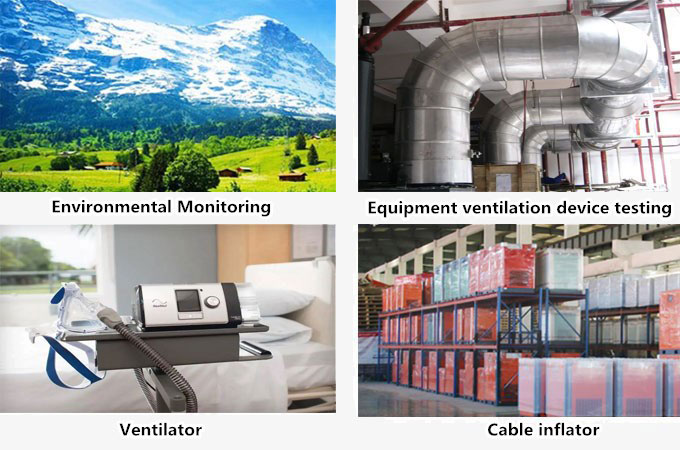

Application

In industrial production, a gas mass flowmeter can be used as a process automation control system detection instrument, can also be used to measure the number of materials in the total table; in energy, primary energy, secondary energy, energy-carrying masses, such as energy measurement, gas mass flowmeter is an indispensable tool in the process of energy management and economic accounting instrument. In environmental protection, gas mass flowmeter can be used for quantitative control of wastewater waste gas; in biotechnology, can be used for blood, urine, etc. detection.

| Model | SISCO-MF4003 | SISCO-MF4008 |

| Flow Range * | 0~2, 5 L/min | 0~20, 50 L/min |

| DN | 3mm | 8mm |

| Gas * | Air, N2O, CO2, O2, N2, Ar. For other gases, please contact us. |

|

| Turn-down Ratio | 100:1 | |

| Accuracy | ±(1.5+0.2)% FS | |

| Repeatibility | 0.25% | |

| Zero Drift | ±30mV | |

| Output Drift | ±0.12%/℃ | |

| Response Time | 10ms (default, 20, 50, 100, 200, 500, 1000 settable) | |

| Power Supply | 8-24V DC, 50mA | |

| Signal Output * | Linear: Analog 1-5V DC (Standard); RS232, RS485 (Optional) | |

| Display | 4-digit 7-segment LED, 2 LED indicator | |

| Display Unit | Instantaneous flow rate: SLPM, Flow accumulation: SL | |

| Display Resolution | 0.001, 0.01, 0.1 L/min settable | 0.01, 0.1 L/min settable |

| Working Pressure | ≤0.5MPa | |

| Pressure Loss | ≤100Pa | ≤600Pa |

| Working Temperature | -10℃ ~ +55℃ | |

| Storage Temperature | -20℃ ~ +65℃ | |

| Humidity | <95%RH (no icing or condensation) | |

| Keyboard | 3 keys | |

| Pin Out | 5 Pins, NS-TECH CD R-5 | |

| Mechanical Connection | BSPT 1/4 (R1/4) | |

| Calibration | Air @20℃, 101.325kPa | |

| Weight | 75g | |

Note: For N2O and CO2, SISCO-MF4003 is selectable with 2 L/min, without 5 L/min; SISCO-MF4008 is selectable with 20 L/min, without 50 L/min.

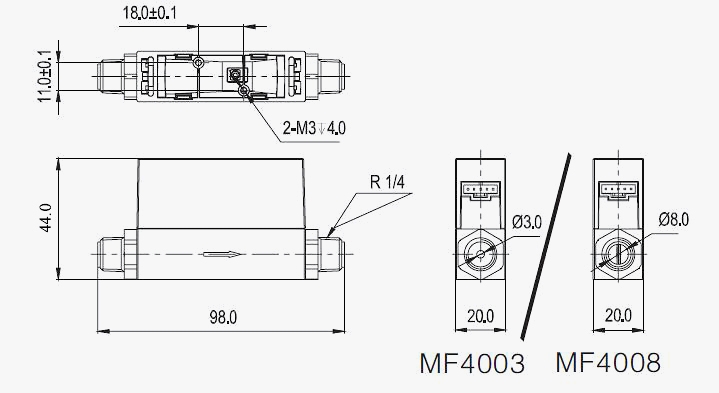

Dimension (Unit: mm)

Q1: Can a gas mass flow meter have perfect accuracy?

A1: In an ideal world, the flow readings from your process meter would be exactly correct, without any type of deviation. Unfortunately, this is not the case, and the errors inherent in measurement must always be identified, accounted for, and minimized as much as possible.

Q2: Does a gas mass flow meter need to be calibrated?

A2: During the production of a flow meter, several steps are required such as coil winding, lining processing, and electrode assembly. This series of operations can cause a certain amount of error and dispersion in the device, so a calibration process is required to correct the accuracy.

Q3: Do gas mass flow meters have temperature and pressure compensation?

A3: Our MF4000/5000/5700 series are all without temperature/pressure compensation. As long as the gas is under working pressure & temperature ranges, the accuracy will be as stated.

Tips: Gas mass flow meter working principle

The principle of a small flow gas mass flow meter is to use the dependence of heat and mass transfer of the flowing gas, in which the temperature change is generated upstream and downstream to obtain the mass flow of gas.

A gas mass flow meter realizes the generation of heat source and the measurement of object temperature at the same time. When the chip is in the working state, a stable temperature field distribution is formed around the sensor. Once a certain mass of gas flows through the sensor, the flow of gas will destroy the distribution of the temperature field. Sensors on the MEMS flowmeter chip measure this change and convert it into an electrical signal, which is amplified, conditioned, and linearized by a specialized circuit transmitter. The mass flow rate or total flow rate of gas can be measured due to the different disturbances caused by the formation of stable temperature field distribution around the sensor with different masses of gas.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.