sisco mass air flow sensor adopts LCD to display instantaneous flow and cumulative flow, clear and intuitive, easy to read, optional flow range 0~50/120/300/800L/min, working pressure 1.5MPa, can be widely used in various fields such as petroleum, gas, chemical, smelting, energy, etc.

High-definition LCD display

- Instantaneous and cumulative flow rate display.

- Clear and intuitive, easy to read.

- Stainless steel base material.

High sensitivity, can measure small starting flow

- Accuracy ±(1.5+0.5FS)%.

- Response time 125ms.

- High anti-interference capability.

Application

sisco gas mass flowmeter with high sensitivity, high accuracy, large range ratio and other characteristics; for the industrial environment, incorporating a variety of anti-interference measures of electromagnetic compatibility design; and has a variety of signal output. The main technical performance is at the international leading level, with high sensitivity, high accuracy, large range ratio and other characteristics; for the industrial environment, it incorporates a variety of anti-interference measures of electromagnetic compatibility design; and has a variety of signal outputs. The product also has its unique performance, installation and maintenance. The product has its unique advantages in performance, installation and maintenance, and can be widely used in various fields such as oil, gas, chemical, smelting and energy.

| Model | SISCO-MF5000 |

| Flow Range (optional) | 0~15 L/min |

| 0~50 L/min | |

| 0~120 L/min | |

| 0~300 L/min | |

| 0~800 L/min | |

| Applicable Gas (optional) | Air |

| Nitrogen (N2) | |

| Oxygen (O2) | |

| Argon (Ar) | |

| Carbon Dioxide (CO2) | |

| Methane (CH4) | |

| Accuracy | ± (1.5 + 0.5 F.S.)% |

| Repeatability | 0.5% |

| Power Supply | DC 8~24V (50mA) |

| Output Signal (optional) | 4-20mA, RS485, pulse 0~5VDC |

| Pressure Rating | 1.5 MPa |

| Working Temperature | -20~60℃ |

| Humidity | <95% RH (no condensation) |

| Pin-out | DB9 |

| Calibration | Air @ 2℃, 101.325 kPa |

| Hazardous Rating | ExiaIICT4 |

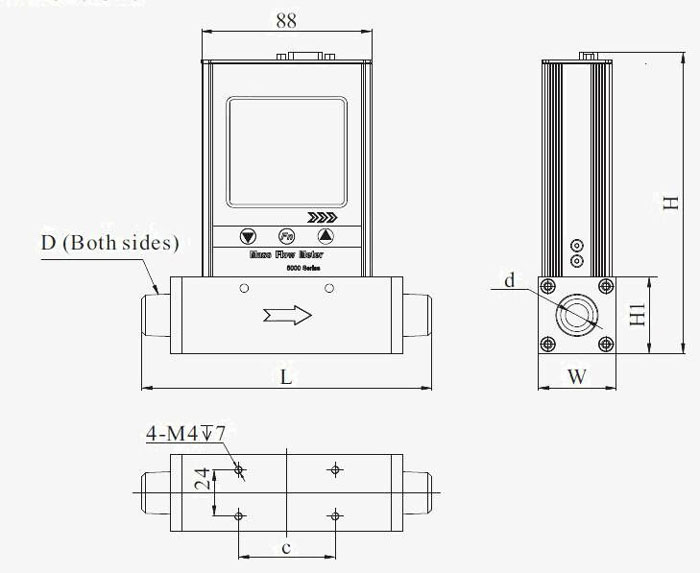

Dimension (Unit: mm)

| Flow Range | DN | D | L | H | H1 | W | d | C |

| 0~15 L/min | 3.0 | 1/8 inch | 118 | 144 | 28 | 38 | Ф 3 | 36 |

| 0~50 L/min | 6.0 | 1/4 inch | 124 | 144 | 28 | 38 | Ф 6 | 36 |

| 0~120 L/min | 8.0 | 3/8 inch | 124 | 151 | 35 | 38 | Ф 8 | 50 |

| 0~300 L/min | 12.0 | 1/2 inch | 150 | 156 | 40 | 40 | Ф 12 | 50 |

| 0~800 L/min | 19.0 | 3/4 inch | 182 | 156 | 40 | 40 | Ф 19 | 70 |

Q1: Can a gas mass flow meter have perfect accuracy?

A1: In an ideal world, the flow readings from your process meter would be exactly correct, without any type of deviation. Unfortunately, this is not the case, and the errors inherent in measurement must always be identified, accounted for, and minimized as much as possible.

Q2: Does a gas mass flow meter need to be calibrated?

A2: During the production of a flow meter, several steps are required such as coil winding, lining processing, and electrode assembly. This series of operations can cause a certain amount of error and dispersion in the device, so a calibration process is required to correct the accuracy.

Q3: Do gas mass flow meters have temperature and pressure compensation?

A3: Our MF4000/5000/5700 series are all without temperature/pressure compensation. As long as the gas is under working pressure & temperature ranges, the accuracy will be as stated.

Tips: Gas mass flowmeter features

- Adopting the microelectromechanical system chip processing technology and the production technology of large-scale integrated circuit and material growth technology, the sensor

The size of the sensor is reduced to the micron level, making the sensitivity of the flowmeter greatly improved. - In a single chip, the integration of multiple sensors, so that the flowmeter range ratio (range degree) greatly improved.

- Sensor zero point stability is greatly improved compared to the traditional thermal mass flow meter.

- Combined with the microcomputer intelligence technology of the secondary instrument, the flowmeter has good repeatability and achieves accurate and reliable measurements.

- Technology progress brought about by the simplification of the structure so that the flowmeter compared to the traditional mechanical instrument, the pressure loss is significantly reduced

- Smaller, greatly reducing energy consumption.

- The use of LCD displays instantaneous flow and cumulative flow, clear and intuitive, easy to read.

- Product integration of electromagnetic compatibility design technology, with higher anti-interference ability.

- Flowmeter with an RS485 communication module, with the upper computer network, can realize centralized management.

- Can choose 4~20mA standard current signal output and pulse output.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.