Installation Method

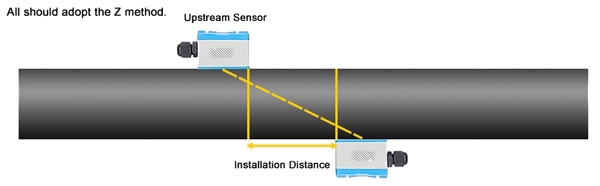

The wall-mounted clamp-on ultrasonic flow meter is popular for its non-contact convenience, and its flexibility in installation is a highlight. The installation method needs to be scientifically selected according to the pipe diameter to ensure measurement accuracy and stability. Among them, the V method and the Z method are the two most commonly used installation schemes, which differ in applicable scenarios, installation points, and measurement principles.

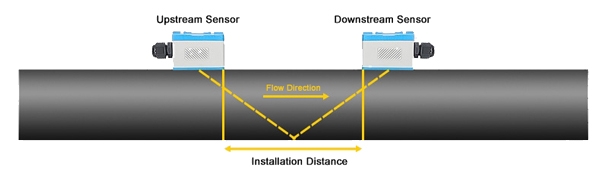

V method: a relatively standard installation method, easy to use, accurate measurement, when installing, the two sensors are horizontally aligned, and their center lines are horizontal with the pipeline axis. The measurable pipe diameter range is about DN15~DN40mm.

Z method: a commonly used installation method, characterized by direct transmission of ultrasonic waves in the pipeline, no reflection (called single-pass), and low signal attenuation loss. The measurable pipe diameter range is DN50~DN6000mm. In actual installation, it is recommended to choose the Z method for pipes above 200mm.

There is a large range of portable ultrasonic flow meter available in the SISCO online store.

Installation Steps

The accurate measurement of the wall-mounted clamp-on ultrasonic flow meter is inseparable from the scientific and standardized installation process. The quality of its installation directly affects the reliability of the flow data and the stability of the equipment operation. Before installation, it is necessary to comprehensively consider the pipeline conditions, fluid state and environmental factors, and follow the following key principles - from pipe section selection to sensor positioning, each step must be strictly controlled to ensure that the flow meter can achieve long-term stable monitoring in an ideal environment with full pipe flow and no interference sources. The specific installation points are as follows:

Step 1: Select a full pipe position, such as a straight pipe section (fluid flows upward) or a horizontal pipe.

Step 2: The installation point should be selected within 10 times the straight pipe diameter upstream and 5 times the straight pipe diameter downstream. There are no valves, elbows, reducers, etc. The uniform straight pipe section should be selected. The installation point should be far away from interference sources such as valves, collapses, high voltage electricity, and frequency converters.

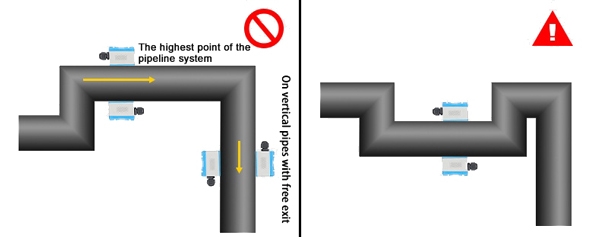

Step 3: Avoid installing on the highest point of the pipeline system or on a vertical pipe with a free outlet (fluid flows downward).

Step 4: For open or half-full pipes, the flowmeter should be installed at the U-shaped pipe section.

Step 5: The temperature and pressure at the installation point should be within the working range of the sensor.

Step 6: Take full account of the scaling condition on the inner wall of the pipe: Although you can choose a scale-free pipe for installation, if it cannot be met, you can consider the scaling as a lining for better measurement accuracy.

Step 7: The two sensors must be installed in the horizontal direction of the pipe axis and installed within the range of ±45° of the horizontal position of the axis to prevent the upper part from being full, bubbles or sedimentation from affecting the normal measurement of the sensor. If the installation site is limited by space and cannot be installed horizontally and symmetrically, the sensor can be installed vertically or at an angle while ensuring that there are no bubbles in the upper part of the pipe.

Correct installation is the prerequisite for obtaining accurate flow data. I hope that these introductions to the V-method and Z-method installation methods and detailed steps can help you be handy in actual operation and make the SISCO wall-mounted clamp-on ultrasonic flow meter a powerful assistant for your fluid measurement. If you need more types of flow meters, you can check further.