The ultrasonic water meter can be used immediately after sticking it without breaking the pipe. It is easy to install and locate, and is widely used in fields related to rivers, water supply, factories, urban sewage pipes, etc.

Full-caliber High-precision Wide-range Monitoring Solution

- The measurement range is large. Different types of sensors can be selected to measure the flow rate of pipelines with a diameter of DN15-DN6000mm. The linearity of the measurement is better than 0.5%, the repeatability accuracy is better than 0.2%, and the measurement accuracy is better than ±1%, which meets the needs of industrial-grade flow monitoring.

- The probe has low power consumption, no need to cut the pipe to open holes for installation, simple and efficient positioning, and is widely used in fields related to rivers, water supply, factories, urban sewage pipes, etc.

- The ultrasonic water flow meter has strong reliability and adopts a low-voltage multi-pulse emission circuit to greatly improve the measurement accuracy, service life, and reliability. It not only improves the measurement accuracy, but also significantly enhances the service life and overall reliability of the equipment.

Fully Protected Anti-interference Intelligent Monitoring System

- Fully Protected Anti-interference Intelligent Monitoring System

The water flow indicator has strong anti-interference ability and adapts to complex environments. It adopts a dual-balanced signal differential emission and receiving circuit to effectively resist strong interference sources such as frequency converters, TV towers, high-voltage lines, etc., ensuring stable and accurate operation in various industrial sites. - ABS electrical interface, waterproof and dustproof, not easily aged and cracked, and long service life. SMT fully automatic patch circuit, high quality, high performance, and more accurate readings.

- The liquid flow meter uses a high-definition LCD display witha backlight display, which makes reading convenient and intuitive. The P67 protection grade housing is durable.

Application

SISCO flow meter calculates the mass flow rate of the fluid based on the power required to maintain the constant temperature difference. Thermal mass flow meters are commonly used in applications where precise measurement of gas flow is required, such as in biotechnology, medical equipment, scientific research, chemical and petrochemical industries.

Medical Equipment

Scientific Research

Petrochemical Industry

Biotechnology

| Model | SISCO-FLOW-TS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Measuring Range | DN 32~100 | DN 50~700 | DN 300~6000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Fluid Temperature | -30~90℃ | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Measurement Accuracy | ±1% | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Repeatability | Better than 0.2% | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Measurement Range | 0~±10m/s | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Working Power Supply | isolation DC 8~36V or AC 85~264V | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Power Consumption | 50mA (The keyboard is not connected, and the buzzer does not sound.) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pressure Level | 1.6MPa | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

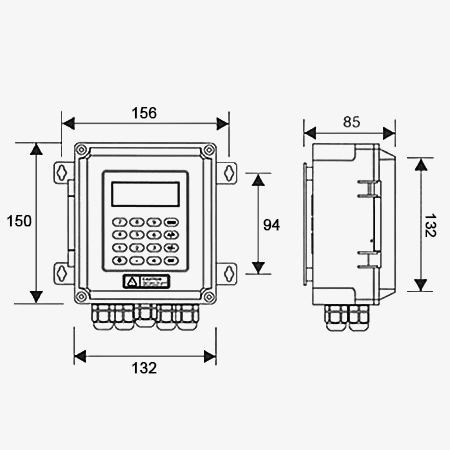

Structure Diagram

Q1: Can a gas mass flow meter have perfect accuracy?

A1: In an ideal world, the flow readings from your process meter would be exactly correct, without any type of deviation. Unfortunately, this is not the case, and the errors inherent in measurement must always be identified, accounted for, and minimized as much as possible.

Q2: Does a gas mass flow meter need to be calibrated?

A2: During the production of a flow meter, several steps are required such as coil winding, lining processing, and electrode assembly. This series of operations can cause a certain amount of error and dispersion in the device, so a calibration process is required to correct the accuracy.

Q3: Do gas mass flow meters have temperature and pressure compensation?

A3: Our MF4000/5000/5700 series are all without temperature/pressure compensation. As long as the gas is under working pressure & temperature ranges, the accuracy will be as stated.

Tips: Advantages of Clamp-on Ultrasonic Flow Meter

The portable ultrasonic flow meter adopts non-contact measurement, can be installed without damaging the pipeline, supports pressure operation, and greatly reduces installation and maintenance costs and the risk of medium leakage; it has a wide range of coverage and can adapt to a variety of media and pipeline materials. It is easy to install and maintain without affecting production. It can not only provide accurate flow data to optimize processes and costs, but also assist in leak detection.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.