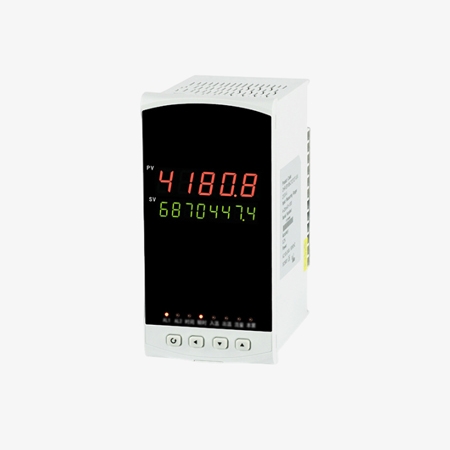

Digital totalizer delivers accurate and consistent measurements, beyond simple flow measurement, this flow totalizer offers extensive communication options, allowing for real-time data transfer and monitoring.

Comprehensive Flow Monimtoring and Accurate Data Accumulation

- The digital totalizing meter can automatically compute and accumulate mass flow data for precise monitoring and control.

- SISCO digital flow totalizer automatically calculates and accumulates standard volume flow, ensuring accurate measurements under varying conditions.

- The flow totalizer provides real-time display of both instantaneous and cumulative flow measurements.

- Users can easily toggle between displaying instantaneous flow rates, elapsed time, and the current cumulative flow value.

Digital Flow Totalizer for Enhanced Accuracy and Control

- The digital totalizer meter allows switching between various measurement inputs and a detailed 11-digit total cumulative flow display.

- The digital flow totalizer automatically compensates for variations in temperature and pressure, ensuring accurate flow measurements.

- When the instantaneous flow is below a set value, the totalizer displays "0," effectively cutting off small, insignificant signals.

- The digital totalizer enables precise control of flow quantities, allowing for automated flow regulation according to preset thresholds.

Applications

SISCO digital totalizer is widely used in industries such as petrochemicals, power generation, food processing, pharmaceuticals, and paper manufacturing to accurately measure and accumulate the total volume or mass of fluids passing through a system. This helps optimize process control, ensure regulatory compliance, and improve efficiency across various applications.

Electric Power

Food Stuffs

Pharmaceuticals

Petrochemicals

| Model | SISCO-FT-E600 | |

| Measurement Accuracy | ±0.2%FS | |

| Input Signals | 37 types of fully switchable signal inputs with input deviation correction function | |

| Alarm Output | Upper and lower limit alarm function, with alarm difference setting, contact capacity | |

| AC125V/0.5A(small)DC24V/0.5A (small), (resistive load) | ||

| AC220V/2A(large)DC24V/2A (large), (resistive load) | ||

| Note: When the load exceeds the relay contact capacity, please do not carry the load directly | ||

| Communication Output | Standard serial communication interface | RS485 two-wire system, communication distance ≤1000 meters |

| RS232 a three-wire system, communication distance ≤ 15 meters | ||

| Standard MODBUS RTU communication protocol | 1 start bit, 8 data bits, 1 stop bit, No parity, baud rate 1200~19200bps | |

| Print Output | RS232 print interface, with micro-type can realize manual, timed, alarm print function | |

| Feeder Output | DC24V±1V, ≤30mA (load resistance ≥750Ω) | |

| Power Supply | Switching power supply AC/DC 100~240V frequency 50/60Hz power consumption≤5W | |

| Switching power supply DC12~36V power consumption≤3W | ||

| Working Temperature | -10~50°C (no condensation, no icing) | |

| Dimension | 80x160x110mm | |

| Weight | 1kg | |

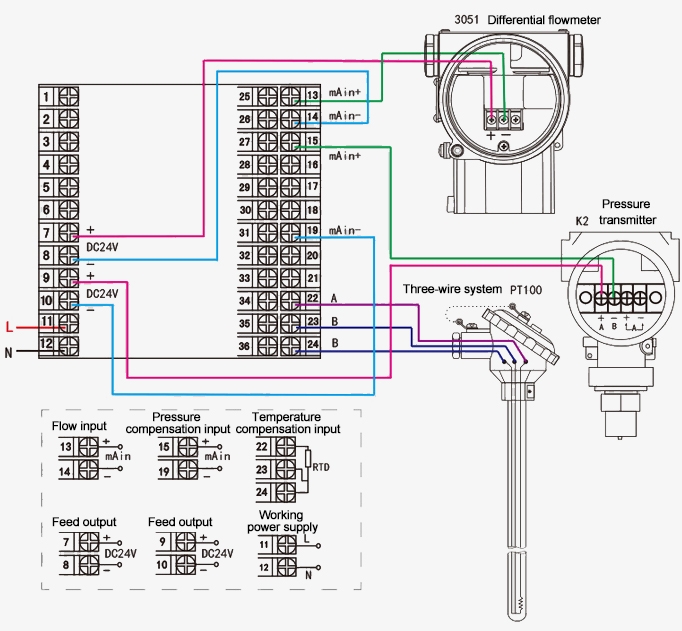

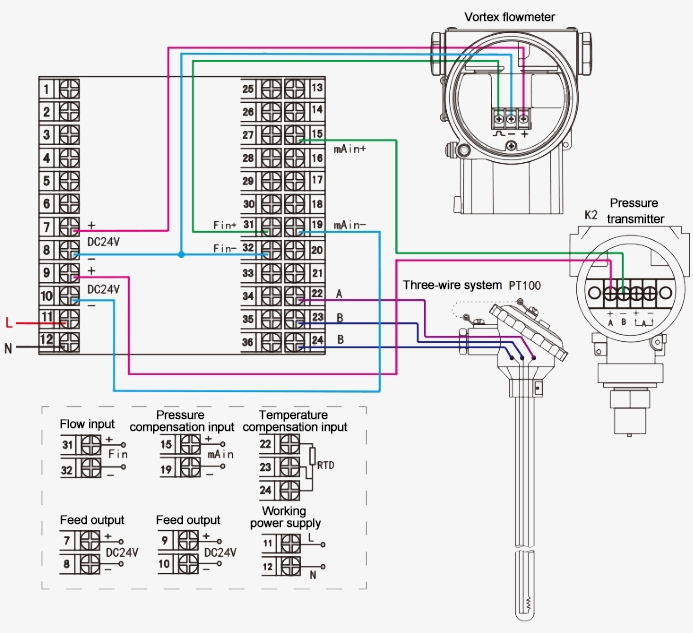

Wiring Methods

Q1: Can a digital totalizer be used with any type of flow meter?

A1: Yes, digital totalizers are designed to be compatible with various types of flow meters, including turbine, electromagnetic, ultrasonic, and differential pressure flow meters. They can be connected to the flow meter’s output signal to accumulate and display the total flow over time. However, it's important to ensure that the totalizer is compatible with the specific type of output signal generated by the flow meter.

Q2: What is the difference between a digital totalizer and a flow meter?

A2: A flow meter measures the instantaneous flow rate of a fluid (either liquid or gas) passing through a system, providing real-time data. In contrast, a digital totalizer accumulates the total flow over time, summing up the flow meter's readings to provide the total volume or mass of fluid that has passed through the system. Essentially, the flow meter gives you the current flow rate, while the totalizer gives you the cumulative total.

Q3: How does a digital totalizer compensate for temperature and pressure variations?

A3: A digital totalizer can be equipped with inputs for temperature and pressure sensors, allowing it to automatically adjust the flow measurements for any variations in these parameters. This compensation ensures that the accumulated flow data is accurate, even under changing environmental or process conditions. This feature is especially important in applications where fluid properties change significantly with temperature or pressure, such as in petrochemical or pharmaceutical processes.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.