High-performance density meter with 0– 2.5 g/cc calibration range. The tuning fork densitometer sensor is composed of two piezoelectric crystals, one piezoelectric crystal generates vibration, the other piezoelectric crystal detects the vibration, and the tuning fork sensor has a built-in temperature sensor to compensate for the vibration of the piezoelectric crystal.

Mounting Thread

- Precision machining, stainless steel material

- Easy installation

- Surface spray plastic, protection grade IP67

316 Stainless Steel Fork Body

- Anti-hanging material

- Fast drip-ping, anti-corrosion

- Safety and health, explosion-proof electrical interface

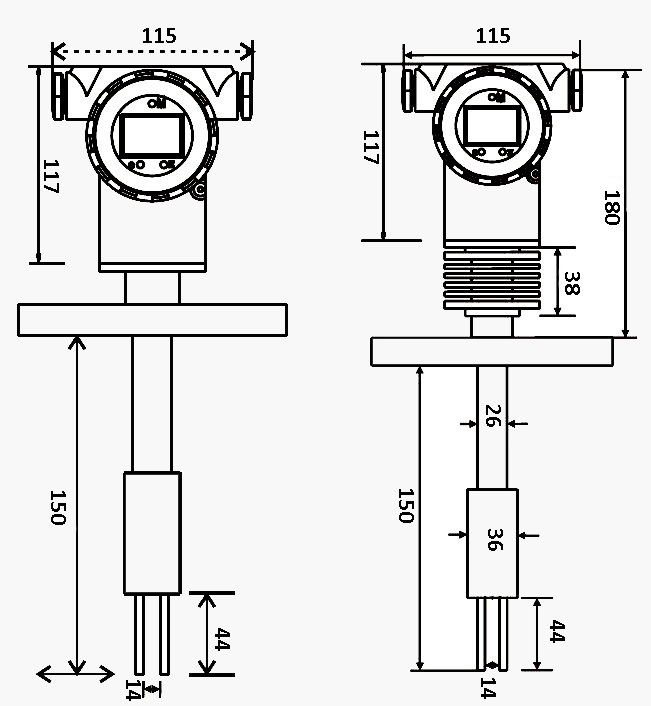

Dimensions (Unit: mm)

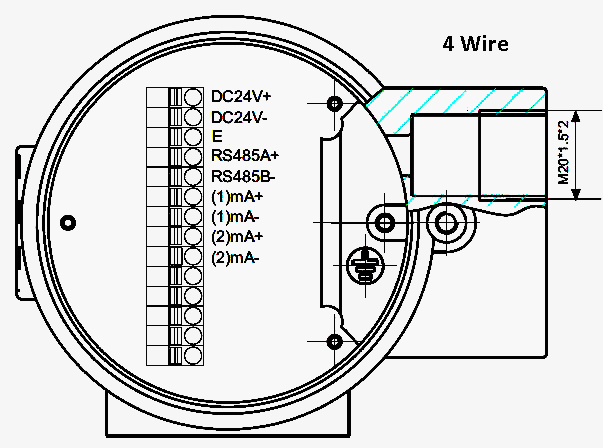

Wiring Diagram

Applications

SISCO tuning fork densitometer is suitable for petrochemical industry, brewing industry, food industry, pharmaceutical industry and mineral processing (such as clay, carbonate, silicate, etc.), specifically for the measurment for chemical, reservoir, ore slurry, medicine tank, cement, printing and dyeing waste, acid tower, and power plant, density detection of stirred mixtures, end-point monitoring of reactors, and interface detection of separators.

| Model | SISCO-APX301-LI |

| Measuring Medium (Optional) | LiOH Solution, Sulfuric Acid Solution, Lime Slurry, NH3·nH2O, Urea Ammonium Nitrate Solution |

| Measuring Range | 0 – 2.5 g/cc (0 – 2500 kg/m3), 0~100.0% |

| Calibration Range | 0 – 2.5 g/cc (0 – 2500 kg/m3), 0~100.0% |

| Measurement Accuracy | ± 0.002 g/cc (± 2 kg/m3), ±0.5% |

| Repeatability | ± 0.001 g/cc (± 0.2 kg/m3) ±0.1% |

| Medium Temperature Range | -50℃ ~ +150℃ |

| Working Pressure (Optional) | 0.2~0.3MPa, Max. Pressure ≤4MPa |

| Fluid Viscosity Range | 0 – 600Cp |

| Media Temperature (Optional) | 0~100℃, 0~150℃ |

| Temperature Coefficient | <0.1 kg/m3/℃ (± 0.5%) After Correction |

| Stress Effect | Negligible |

| Built-in Temperature Sensor | Digital Sensor |

| Electrical Connection (Optional) | M20*1.5, G1/2, NPT1/2 |

| Connection Type (Optional) | G1/2” Thread/ DN50 Flanged/ DN80 Flanged/ 1/2” Trip Clamp/ 2” Trip Clamp |

| Fork Body Coating | Standard PTFE or PFA |

| Power Supply | 24VDC, ≥50mA |

| Analog Signal Output | 4-20mA, 0-1000Hz, RS485 Modbus, 4 Wires |

| Output Accuracy (20℃) | ± 0.1% of reading or ± 0.05% FS |

| Output repeatability (-40~+85℃) | ± 0.05% FS |

| Protection Level | IP65 |

A1: What is a density meter used for?

Q1: Density meters are instruments that measure the density of a sample liquid or gas. Digital density meters are used in the pharmaceutical, petroleum, chemical, and food and beverage industries for quality control and in research and development.

A2: How does a fork density meter work?

Q2: The Fork Density Meters use vibrating fork technology to measure density directly, and can be used in process control where density is the primary control parameter for the end product or as an indicator of another quality control parameter, such as %solids or %concentration.

A3: How to use a density meter?

Q3: Density meters work by measuring the oscillation of a glass tube that contains the sample. There are digital density meters that can measure specific gravity and refraction index as well as the density of a sample.

Tips: How to maintain a tuning fork density meter?

When the tuning fork density meter is used, how to maintain it to ensure that the tuning fork density meter can be used better.

- The vulnerable part of the tuning fork densitometer is its sensor head, and some small damages will cause damage to the densitometer. To protect the sensor from damage during transportation and installation, the protective cover should only be removed before installation. Do not dismantle first.

- Generally speaking, the tuning fork density meter has been adjusted to the best state before leaving the factory. If you are not a professional, please do not adjust it at will.

- If it is found to be abnormal during work, first check whether the power supply and ground wire are connected well, and then check elsewhere. Check it out in order of the easiest and the hardest.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.