Energy meters are crucial devices for measuring and recording electrical energy consumption in various applications. They come in different types, each designed to suit specific purposes. In this article, we will explore the various classifications and types of energy meters commonly used, their functions, and their applications across different sectors.

Classification of Energy Meters

Classification by Electrical Circuit

- Direct Current (DC) Energy Meters

- Alternating Current (AC) Energy Meters

- Single-phase Energy Meters

- Three-phase Three-wire Energy Meters

- Three-phase Four-wire Energy Meters

Classification by Working Principle

- Electromechanical Energy Meters

- Electronic Energy Meters (Static Energy Meters)

- Fully Electronic Energy Meters

- Electromechanical-Electronic Hybrid Energy Meters

Classification by Structure

- Integrated Energy Meters

- Split-type Energy Meters

Classification by Purpose

- Active Energy Meters

- Reactive Energy Meters

- Maximum Demand Meters

- Standard Energy Meters

- Multi-rate (Time-of-Use) Energy Meters

- Prepaid Energy Meters

- Loss Energy Meters

- Multifunction Energy Meters

Classification by Accuracy Grade

- Standard Installation Energy Meters (0.2, 0.5, 1.0, 2.0, 3.0)

- Portable Precision Energy Meters (0.01, 0.02, 0.05, 0.1, 0.2)

Types of Energy Meters and Their Applications

Energy meters are employed in various sectors to measure and manage electricity consumption. Here are some of the common types and their applications:

- Industrial Sector: In industrial settings, energy meters help monitor the energy consumption of machines and equipment, providing accurate data to aid in energy management and decision-making. They also detect equipment operational statuses and load conditions, assisting in energy efficiency and reducing wastage.

- Transportation Sector: Energy meters are used to monitor the energy consumption during the charging of electric vehicles and other transportation equipment. They help vehicle owners and fleet managers understand energy usage, enabling efficient maintenance and operation planning.

- Agriculture Sector: Agriculture relies on energy-intensive activities such as irrigation systems and crop cultivation. Energy meters assist farmers in managing and optimizing energy use, monitoring energy consumption at various stages of agricultural production, and supporting sustainable agriculture.

- Healthcare Sector: Hospitals and healthcare facilities require substantial energy for medical equipment and building operations. Energy meters track energy consumption, helping with resource management and implementing energy-saving measures.

Advanced Features of Modern Energy Meters

With technological advancements, energy meters have evolved to offer more than just basic energy measurement. Here are some of their advanced features:

- Remote Meter Reading: Modern electronic energy meters can communicate remotely through interfaces and internet connections, allowing for cloud-based remote meter reading. This feature automates data collection and improves service efficiency.

- Load Monitoring: Energy meters provide real-time monitoring of load conditions, allowing for more accurate load analysis and prediction, helping to prevent overloads.

- Anomaly Data Handling: Electronic energy meters are equipped with smart features for precise and timely detection of anomalies, such as meter malfunction or exceeding measurement limits. They can trigger event handling and log the occurrences.

- Mechanical Energy Meters: Mechanical energy meters, also known as induction meters, share a fundamental structure consisting of measuring components, compensation and adjustment mechanisms, and auxiliary parts such as the casing, frame, terminal box, and nameplate. Here are two common types:

- Long-Lifespan Energy Meters: The lifespan of a mechanical energy meter primarily depends on the wear and tear of its lower bearings. To extend the meter's life, modern energy meters use advanced bearing structures, including steel ball jewel bearings, graphite bearings, and magnetic bearings. For instance, magnetic bearings rely on repelling forces between magnets to suspend rotating components, reducing mechanical wear and prolonging the meter's lifespan. Many long-lifespan energy meters are adopting magnetic bearing technology. Traditional mechanical energy meters typically use single jewel bearings and have a lifespan of around 5 years. In contrast, long-lifespan meters with magnetic or dual jewel bearings can extend their lifespan to approximately 10 years.

- Wide-Range Energy Meters: With the rising living standards, households are increasingly using high-capacity electrical appliances. If older single-range energy meters are used, the risk of under-measurement at low loads or meter burnout during simultaneous appliance use increases. Wide-range energy meters address these issues by having a flexible range. They can accurately measure any combination of household appliances as long as the total current falls within the meter's specified range. These meters are often labeled as high overload capacity meters, with overload capabilities reaching up to 2-4 times their rated current. This flexibility ensures accurate measurement and prevents meter damage due to overload. For example, a single-phase meter labeled as "Class 2.0, 220V, 10(40)A" indicates an overload capacity of 4 times. As long as the current falls within the range of 10-40A, the meter maintains its accuracy, making it ideal for residential use during both normal and high-demand periods.

Electronic Energy Meters

Electromechanical energy meters with single energy measurement functionality face limitations when it comes to tasks like time-of-use measurement, load control, parameter pre-setting, data collection, storage, and real-time transmission. To address these challenges, fully electronic, multifunctional energy meters have emerged.

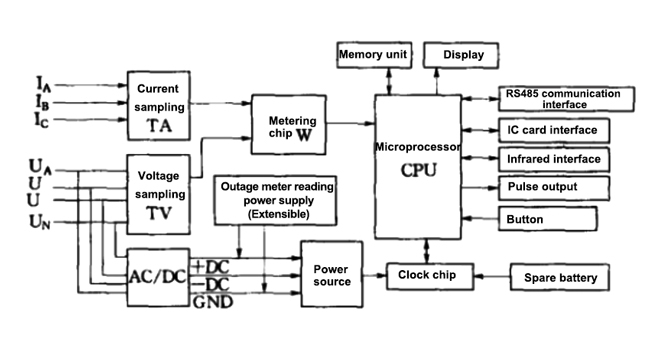

It first samples the voltage and current of the actual line and generates a power signal through the UI multiplier; secondly, it uses a U/f (voltage/frequency) converter to convert the power signal into a pulse signal with a certain frequency, and the counter converts the pulse The signals are accumulated to obtain electrical energy. The structure of the multifunctional electric energy meter is as shown in the figure.

The metering chip W in the figure is a highly integrated dedicated three-phase metering chip, which completes the generation of the power signal P (i.e. UI product); the frequency conversion of P-f. Functions such as pulse accumulation, time-sharing metering, phase loss processing, liquid crystal display, and RS485 communication are controlled by the microprocessor CPU.

Features

These meters incorporate advanced technology and functionality for improved energy management, making them suitable for various applications. They offer several key features:

- Measurement and Storage: Multifunctional energy meters can measure and store data for multiple time periods, including single or bidirectional active and reactive energy. They provide real-time readings of parameters like current power, maximum demand, and power factor. The meters can store data for at least one complete billing cycle.

- Monitoring: Multifunctional meters can monitor customer power and maximum demand, helping to prevent electricity theft by analyzing load profiles.

- Control: These meters can implement time-of-use and load control. Time-of-use control is essential for multi-rate billing, while load control allows the meter to manage the load based on remote commands or programmed settings, considering time and load quotas. Meters with IC card interfaces offer prepaid functionality with features such as low balance warnings and delayed disconnection alerts when purchased energy is about to run out.

- Management: Electronic energy meters connect to power systems through communication interfaces. This allows for remote data exchange with external systems and secure, accurate parameter adjustments based on the meter's 12-digit decimal address. Users with the appropriate permissions can configure parameters such as time-of-use rates, power limits, remaining energy alarm thresholds, and more. These meters offer real-time power readings and facilitate data collection for system dispatch, energy control, billing, and business operations.

Energy meters are crucial tools in electrical measurement, providing accurate data for billing, monitoring, and control. Mechanical and electronic meters cater to different needs and are designed to meet various requirements. With advancements in technology and a broader range of functions, electronic energy meters have become indispensable for modern energy management, addressing complex challenges and facilitating precise measurement and control.