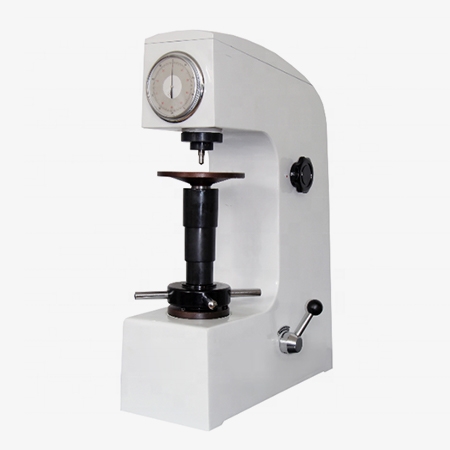

SISCO analog Rockwell hardness tester is a mechanical device used to measure the hardness of materials by determining their resistance to indentation. It operates without digital components. This type of hardness tester is widely used in quality control for metals and plastics due to its simplicity, reliability, and fast results without the need for complex electronics or software.

Analog Display

- Immediate and Clear Readings. The pointer dial provides a direct and analog display of the hardness value. Unlike digital displays, which may suffer from battery or electronic issues, a mechanical dial is always visible and functional.

- User-Friendly Operation. The dial in manual Rockwell hardness tester is intuitive and easy to read, especially for experienced technicians familiar with analog gauges. No complex settings or programming are required, which simplifies training and minimizes the risk of operational errors.

- No Power Dependency. Mechanical dial does not require power to operate, making it ideal for use in locations with limited electricity.

Rockwell Hardness Tester Adopts Cast Iron Material

- Superior Structural Stability. Cast iron is well-known for its rigidity and dimensional stability. In a Rockwell hardness machine, structural integrity is critical because any flexing or vibration can distort the force application and, consequently, the accuracy of the hardness readings. Cast iron minimizes deflection under load due to its high modulus of elasticity.

- Long-Term Durability. Cast iron is highly resistant to wear and deformation, making it ideal for the demanding conditions under which the Rockwell hardness tester operates. The machine is often used for years in industrial environments. The cast iron frame provides a robust and long-lasting base.

Applications

Rockwell hardness testers are widely used in various industries to measure the hardness of materials, particularly metals and alloys. One major application field is the metallurgical industry, where it ensures the quality and uniformity of steel, aluminum, and other metal products. In automotive manufacturing, Rockwell hardness testing is used to evaluate engine components, gears, and axles for wear resistance and durability.

Metal Processing

Mechanical Manufacturing

Laboratory

Metallurgical Industry

| Model | SISCO-HT-HR-150A |

| Rockwell Scale | HRA, HRB, HRC |

| Test Force | 60kgf(588.4N), 100kgf(980.7N), 150kgf(1471N) |

| Initial Test Force | 10kgf(98.7N) |

| Measurement Range | 20-95HRA, 10-100HRBW, 20-70HRC |

| Hardness Indication | Dial pointer |

| Specimen Allow Maximum Height | 170mm |

| Press Head Center to Machine Wall Distance | 135mm |

| Hardness Resolution | 0.5HR |

| Dimension | 466*238*630mm |

| Net/Gross Weight | About 67kg/ 80kg |

Dimension:

Q1: What is a Rockwell hardness tester?

A1: A Rockwell hardness tester is a device used to measure the hardness of materials, typically metals and alloys, by assessing their resistance to indentation. It operates by pressing a steel or carbide ball, or a diamond cone (indenter), into the material's surface under a specific load. The depth of the indentation is then measured, which determines the Rockwell hardness number (HR).

Q2: What factors can affect the accuracy of Rockwell hardness tester readings?

A2: Several factors can affect the accuracy of Rockwell hardness gauge readings. Surface preparation is critical; rough, dirty, or uneven surfaces can distort results. Test specimen thickness must meet minimum requirements to avoid substrate influence. Incorrect or worn indenters, improper test loads, or mechanical misalignment of the tester can lead to errors.

Q3: What maintenance is required for a Rockwell hardness tester?

A3: Maintenance for a Rockwell hardness tester includes regular cleaning to remove dust and debris from the indenter and anvil. Ensure the indenter is free from damage or wear. Check for any loose screws or parts and tighten them if needed. Store the tester in a dry, dust-free environment to prevent corrosion.

Tips: What are the advantages of an analog Rockwell hardness tester?

Analog Rockwell hardness testers offer several advantages, particularly in durability and simplicity. These testers are highly reliable due to their mechanical operation, requiring no electrical power or complex electronics. They provide consistent results with minimal maintenance and are ideal for harsh environments where digital devices might fail. Their straightforward design makes them easy to operate and calibrate, even for inexperienced users. Additionally, analog testers often come at a lower cost, making them a budget-friendly choice for small workshops or educational settings.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.