The diamond and gem tester adopts a clear hardness indicator scale and indicator lights, differentiating genuine diamonds from fakes based on differences in thermal conductivity and hardness, allowing for quick identification. It is compact and easy to carry. The gem hardness tester is widely used in jewelry sales, gemstone appraisal, and personal collection authentication.

Alloy metal probe, visual hardness characteristics

- The diamond tester pen, based on the principle of diamond's high thermal conductivity, is used for quick identification of genuine diamonds. It is also suitable for preliminary testing of various gemstones and imitation gemstones such as jade, crystal, etc.

- The diamond detector machine uses an alloy metal probe tip that generates a small amount of heat when powered on. When the probe touches the surface of the object being tested, different materials exhibit different heat conduction speeds.

- Due to its extremely high thermal conductivity, a diamond quickly conducts heat, causing the diamond checker to immediately trigger a beeping sound, accompanied by changes in the scale and indicator lights, thus providing a visual indication of the authenticity and hardness characteristics of the gemstone.

Compact structure, simple operation

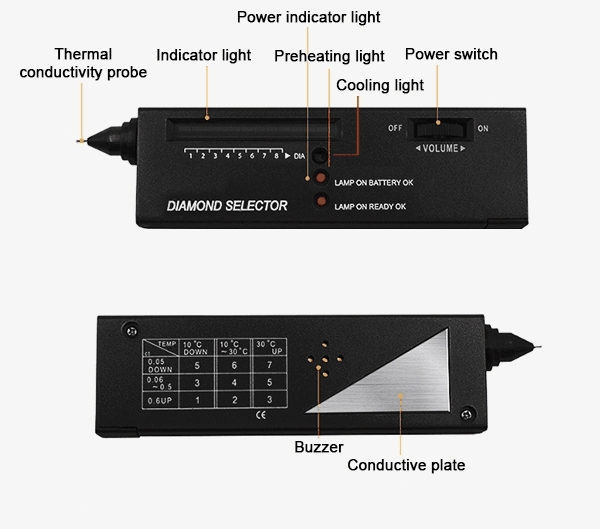

- The gem tester machine is equipped with a clear hardness indicator chart, a preheating indicator light, and a three-color status indicator light, which intuitively displays the diamond checking machine's working status, battery status, and test feedback, ensuring testing is performed after stable preheating to improve detection accuracy.

- The gemstone tester has a compact structure, sensitive response, and simple operation, making it easy for even first-time users to quickly get started. The gemstone tester machine is suitable for various applications such as jewelry sales, gemstone appraisal, quality inspection, and personal collection identification.

Diamond Tester Pen Structure

Diamond Detector Machine Usage Procedure

- After installing the battery, slide the power switch to the right. The diamond tester will enter the preheating state. Wait a moment; when the preheating indicator light illuminates, it means the diamond detector has reached a stable working state and is ready for testing. Before use, observe the indoor ambient temperature and consider the weight of the diamond, referring to the corresponding indicator light scale range for more accurate test results.

- During testing, set the three-color indicator light to the 4th position. Your finger must press the triangular metal piece on the back of the gemstone tester pen to ensure good conductivity. Keep the probe perpendicular to the surface of the object being tested:

- If it is a diamond, the indicator light will quickly jump to the 8th–9th position or higher, entering the red light area, and simultaneously emit a "beep" sound;

- If it is jade, the indicator light usually illuminates between the 5th and 7th positions, indicating that its hardness reaches the corresponding range, but no sound will be emitted.

Application

The diamond tester pen is primarily used for quickly identifying the authenticity of diamonds. By detecting the thermal conductivity of gemstones, it differentiates between natural diamonds and imitation diamond materials. It is widely used in jewelry retail stores, pawnshops, jewelry processing plants, appraisal institutions, and for personal collection testing. It can also assist in identifying common diamond simulants such as crystal, jade, gemstone.

Jade

Crystal

Jadeite

Diamond

| Model | SISCO-DT-B2009 |

| Dimensions | 4*15.5 (cm) |

| Battery | 9V (The user needs to provide their own battery. ) |

| Indicator Light Segments | Glass: 5 segments; Jade: 5-6 segments; Zircon: 5 segments; Jadeite, Crystal: 7 segments; Diamond, Moissanite: 9 segments (Cannot test metal) |

Q1: What is a diamond tester?

A1: A diamond tester is a portable testing tool used to quickly identify the authenticity of diamonds. It is commonly found in jewelry stores, gemological laboratories, and private collections. Gemstone detector is typically designed based on the physical property of diamonds, which have extremely high thermal conductivity (or, in some models, high electrical conductivity). A metal probe contacts the surface of the gemstone, quickly determining whether the object being tested is a diamond.

Q2: What does the "beep" sound from a diamond tester mean?

A2: When a diamond detector emits a continuous or distinct "beep" sound, it usually indicates that the thermal conductivity (or electrical conductivity) of the tested gemstone has reached the threshold for diamond identification, and the diamond detector machine determines that it is likely a real diamond. If there is no sound or only a low-level warning, it generally indicates that the gemstone is glass, zircon, or other diamond-like materials. However, it should be noted that some high-quality imitations (such as moissanite) may also trigger an alarm on some gem tester machine, so other testing methods should be used in conjunction with the tester for a comprehensive assessment.

Q3: What is the purpose of a diamond tester?

A3: A diamond checker can quickly and initially distinguish between diamonds and diamond imitations, helping users improve their judgment efficiency and reduce the risk of misjudgment in non-laboratory environments. The gem tester machine is easy to operate and has a fast detection speed, making it suitable for daily screening and on-site testing. It is more often used for initial screening and auxiliary judgment.

Tips: How does a deamond pen work?

A gemstone tester works by measuring the physical properties of a stone—most commonly thermal conductivity and sometimes electrical conductivity—and comparing them to known values of gemstones. When the probe touches the stone’s surface, the device applies a small amount of heat or electrical signal and detects how quickly it is transferred. Because gemstones like diamonds have very high thermal conductivity, the tester can quickly distinguish them from glass or common simulants.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.