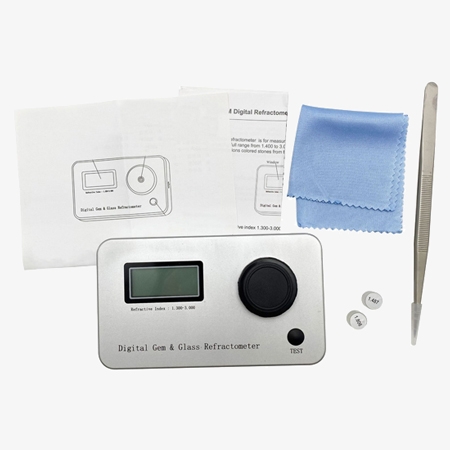

Upgrade your gem testing with the digital gem refractometer for Jewelry, designed for professionals who need fast, accurate, and non-destructive gemstone identification. This advanced refractometer for jewelry uses precision optical technology to deliver reliable refractive index (RI) readings—essential for verifying diamonds, moissanite, and colored gemstones.

Fast & Accurate Non-Destructive Gem Testing

- The digital gem refractometer offers non-destructive, fast, and accurate refractive index measurement for gemstones, making it an essential tool for professional gem identification.

- The digital gem jewelry refractometer with a wide RI test range of 1.300 to 3.000, it is suitable for identifying a broad variety of gemstones including diamonds, moissanite, and colored gems.

- Built with high-sensitivity sensors and intelligent electronics, it delivers precise readings with minimal user effort.

- SISCO jewelry refractometer Features an easy-to-read LCD screen that clearly displays the refractive index value, improving readability and workflow efficiency during gemstone testing

Total Internal Reflection for Accurate Gem ID

- Unlike traditional models, this gemstone refractometer does not require refractive oil, reducing maintenance and eliminating mess during use.

- Based on the principle of total internal reflection, the refractometer accurately captures key optical characteristics to aid in determining the type of gemstone.

- Allows users to differentiate between uniaxial and biaxial crystals, enhancing its value in gemology labs and jewelry quality inspection.

- Designed for professional and educational use, this portable refractometer is ideal for jewelers, gemologists, and gem identification enthusiasts.

Applications

SISCO portable gem refractometer is an essential tool for jewelers, enabling quick and accurate identification of gemstones, diamonds, and precious metals like gold and silver. It ensures precise refractive index measurements, helping professionals distinguish between different gems and verify their authenticity.

Jewelry

Diamond

Silver

Gold

| Model | SISCO-RM-GH995 |

| Measuring Range | Refractive index 1.300-3.000 RI |

| Measurement Accuracy | 0.001 RI |

| Measurement Error | ±0.005 RI |

| Power Supply | 700mA Lithium Battery |

| Battery Life | 10.000 Times |

| Dimension | 135x78x24mm |

| Weight | 250g |

Dimension

Q1: What is a gem refractometer used for?

A1: A gem refractometer is a precision instrument used to measure the refractive index (RI) of gemstones. It helps gemologists identify and verify the type of gemstone by comparing the light refraction in the stone to known values.

Q2: Is it difficult to use a gem refractometer?

A2: While the gem refractometer is easy to use, some basic knowledge of gemology is helpful. The process involves placing the gemstone on the prism, adjusting the focus, and reading the refractive index. With practice, users can quickly learn to make accurate measurements.

Q3: How should I care for my gem refractometer?

A3: To ensure longevity and accurate results, keep your gem refractometer clean and dust-free. Use a soft cloth to gently clean the eyepiece and prism. Avoid using harsh chemicals or abrasive materials to prevent scratches. Regular calibration is also recommended for consistent performance.

Tips: How to use the SISCO digital gem refractometer?

- Before use, clean the measuring platform—specifically, the small raised circular area in the center of the black surface at the top right. Any dirt or contamination can significantly affect the measurement results.

- Press the TEST button once to power on the device. The display will show a value of 1.000. Place the sample at the center of the measuring hole. Make sure to wipe the measurement surface of the sample clean with the included cloth. The surface must lie flat and in full contact with the platform, without any tilt.

- Press the TEST button again. The value shown on the screen is the refractive index of the sample. To ensure accuracy, repeat the measurement five times: place the sample in the center, press the TEST button, and record the value. Remove and reposition the sample, press the TEST button again, and record the new reading. Repeat this five times. The most frequently appearing value is considered the correct refractive index.

- For birefringent gemstones, measure the refractive index in one orientation, then rotate the sample 180° and measure again. Take the average of the two values.

The digital gem refractometer is calibrated before shipping and ready to use. However, after long-term transport or use, recalibration may be necessary.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.