Cheap price load cell controller is a device used for weighing and batching applications. It has an RS-232 interface and can control the value of four different materials. The controller uses a CPU device and a 3-point principle for A/D conversion, which provides high accuracy and quick speed. This digital weight controller is suitable for weighing or force measuring display, constant value control, sensor signal transmission and other occasions.

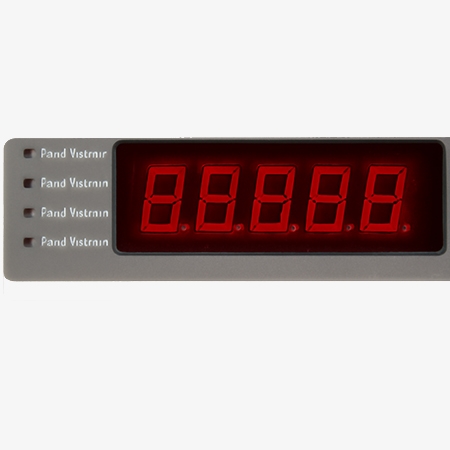

Digital weighing indicator with a 0.8 inch red LED display

- Clear LED Display: The product is equipped with two red seven-segment LED displays, each showing six digits for clear and readable numerical output.

- Functional Labels: Labels on the left side, marked “Fixed Value 1,” “Fixed Value 2,” and “Fixed Value 3,” indicate that the device can handle multiple preset values or load inputs.

- Intuitive Button Layout: The button area below features numeric keys, a switch, and calibration buttons. The design is simple and easy to operate, allowing users to quickly adjust and control the device.

- Clear Status Indicators: The device has status indicator lights and buttons with different colored borders, improving visibility and ease of use during operation.

The weighing scale indicator has a protective anti-collision edge design

- Bright Red Digital Display: The display uses red LED digits, presenting clear, easily readable values, ideal for various industrial applications to ensure visibility of data.

- Multi-Functional Control Interface: The button layout below includes “Enter,” “Calibration,” and other control buttons, making it convenient for users to adjust settings and operate the device.

- Distinct Functional Labels: The display is accompanied by several functional labels, such as “Fixed Value” and other control options, highlighting the adjustable parameters of the device.

- Advanced Custom Control Keys: It includes specialized buttons such as “Switch” and “Zero Adjustment,” allowing users to quickly set or calibrate the device based on their needs.

Applications

SISCO weighing indicators are widely used for accurate weight measurement in various industries. They are essential in warehouses for inventory management, in supermarkets for weighing products and pricing, in logistics and transportation to prevent overloading, and at ports for weighing containers and ensuring safe cargo handling. These devices enhance efficiency and precision across these applications.

Logistics and Transportation

Warehouse

Wharf

Supermarket

| Model | SISCO-WI-GGD-33A |

| Sensor Excitation Power Supply | DC10V, 150mA, up to four or more sensors with an internal resistance of 350 ohms can be used in parallel |

| Sensor Input Signal Range | 0-30mV (0-3mV/V) |

| Zero Adjustment Range | 0-30mV |

| Maximum Display Resolution | 65,000 characters |

| Maximum Display Sensitivity | 2,000 characters/mV |

| Measurement Nonlinearity | 0.01% FS |

| Sampling Speed | 75 times/s |

| Analog Transmission Output Signal | 4-20mA, maximum external load impedance not exceeding 500 ohms |

| Accuracy of Analog Transmission Output Signal | 0.03% |

| Output Characteristics of Constant Value Control Switch | Relay normally open switch output, AC125V, 0.5A |

| Display | Five digit LED digital display and five digit LED light-emitting tube status indication |

| Keyboard | Five composite touch keyboards |

| Working Ambient Temperature | 0~40 ℃ |

| Working Power Supply | AC220V, 50Hz, 5W |

Q1: What is a weighing indicator?

A1: A weighing indicator is a device used in conjunction with weighing scales or load cells to display and process weight measurements. It receives electrical signals from the load cells, converts them into readable weight values, and displays the information on a screen. Depending on the model, weighing indicators can offer additional features like data storage, connectivity for data transfer, and advanced weighing functions such as tare, counting, and totalizing. They are commonly used in various industries, including logistics, warehousing, retail, manufacturing, and more, to ensure accurate weight readings and efficient process management.

Q2: Can weighing indicators be used with different types of scales?

A2: Weighing indicators can be used with a variety of scales, making them versatile tools in numerous industries. They are compatible with different types of scales, such as platform scales for heavy-duty industrial use, bench scales for smaller applications like retail or laboratories, floor scales for bulk weighing in warehouses, and weighbridges for weighing large vehicles in logistics and transportation. Additionally, they can be used with hopper and tank scales in manufacturing and crane scales for suspended loads in construction or shipping. This flexibility allows Weighing Indicators to meet diverse weighing needs across multiple sectors.

Q3: How do weighing indicators communicate with other devices?

A3: Many weighing indicators support communication protocols like RS232, RS485, Ethernet, USB, or wireless options. This allows them to connect to computers, printers, or control systems for data logging or remote monitoring.

Tips: Can this digital weight controller be used with multiple scales?

Yes, a digital weight controller can typically be used with multiple scales, depending on its configuration and capabilities. Many digital weight controllers are designed to handle multiple load cells or weighing systems at once, making them suitable for industrial applications where several scales are used in parallel or connected to a single control system.

Key considerations include:

- Input Channels: The controller must have multiple input channels to connect to multiple load cells or scales.

- Scalability: Some models are specifically designed to work with more than one scale, and they may allow you to switch between different weight measurements or display readings from various sources.

- Communication Protocols: Ensure that the controller supports communication protocols (like RS232, RS485, or Ethernet) that allow connection to multiple devices or scales.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.