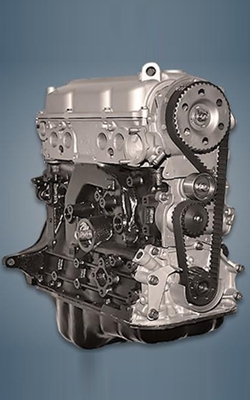

SISCO engine compression tester kit is an essential tool for diagnosing the health of your engine. With easy-to-read pressure readings, this kit allows you to quickly assess engine performance and pinpoint potential problems. Whether you're performing routine maintenance or troubleshooting engine issues, the engine compression tester set is a must-have tool for any mechanic or DIY enthusiast looking to maintain optimal engine health.

Sophisticated Dial Design

- Fine and Detailed Scale: The engine comprission tester is designed with a finely graduated dial, allowing users to read even subtle changes in fuel pressure with ease and confidence.

- Accurate Pressure Display: This cylinder compression tester tester provides a precise indication of the fuel pressure values, ensuring that measurements are both reliable and easy to interpret during vehicle diagnostics.

- Low-Range Precision: With a minimum scale that extends to very low pressure levels, the gauge can capture slight variations that are critical for troubleshooting fuel system issues.

- Essential Diagnostic Tool: By clearly showing the fuel system’s pressure status, it helps mechanics and technicians accurately assess the condition of the fuel pump, regulator, and injectors, leading to more efficient maintenance and repairs.

Orderly Storage and Easy Management

- Custom-Molded Toolbox Design: The petrol engine compression tester set comes in a specially designed toolbox with custom-molded grooves, ensuring that each component has its own dedicated compartment.

- Secure and Fixed Placement for Each Tool: Every adapter, connector, and the gauge itself is held firmly in place within the toolbox. This secure positioning prevents the tools from moving or rattling during transport, reducing the risk of damage and making the set reliable for both workshop use and mobile diagnostics.

- Loss Prevention and Easy Organization: The structured layout eliminates the risk of misplacing smaller parts, such as fittings and adapters. With clearly defined slots for each tool, users can quickly identify missing components, saving time during setup and ensuring complete readiness for each diagnostic task.

- Neat and Professional Work Environment: By keeping all components organized in one compact case, the toolbox helps maintain a clean and professional workspace.

Application

SISCO engine compression tester kit is used to measure cylinder compression in gasoline engines, helping diagnose issues like worn piston rings, valve problems, a blown head gasket, or cylinder head damage. It’s essential for identifying causes of poor engine performance, such as rough idling, misfires, or starting difficulties, and is commonly used in automobiles, motorcycles, small engines and light trucks.

Motorcycle

Light Truck

Small Engine

Automotive

| Model | SISCO-ADT-G326 |

| Measuring Range | 0-300 psi |

| Gauge Size | 3 inches |

| Gauge Type |

Dual-scale, analog dial with color-coded markings for easy reading |

| Hose Length | 17.7 inches |

| Threaded Adapters in Sizes | M10, M12, M14, M18 |

| Weight | 5kg |

Q1: What is an engine compression tester kit?

A1: An engine compression tester kit is a diagnostic tool used to measure the compression pressure within the cylinders of an engine. It helps assess the internal health of the engine, specifically evaluating the condition of critical components such as piston rings, valves, and head gaskets. The kit includes a gauge, hoses, and adapters for easy connection to the engine, providing vital insights into the engine's internal health.

Q2: Why do I need an engine compression tester kit?

A2: You need an engine compression tester kit to diagnose potential issues in your engine, such as worn piston rings, damaged valves, or a blown head gasket. By measuring the compression in each cylinder, the kit helps identify performance problems like rough idling, loss of power, or difficulty starting the engine. Early detection of these issues can save time and money by allowing you to address problems before they lead to more serious engine damage.

Q3: How to use the engine compression tester kit?

A3: Here are the steps by using the cylinder compression tester:

- Prepare the Engine: Turn off the engine and remove the spark plugs.

- Attach the Tester: Screw the tester hose into one spark plug hole.

- Crank the Engine: Turn the engine over for 3-4 seconds to measure the compression.

- Read the Gauge: Check the PSI reading on the gauge and record it.

- Repeat for Each Cylinder: Test all cylinders in the same way.

- Compare Results: Compare readings. Low or inconsistent pressure may indicate engine problems.

- Reinstall Spark Plugs: Put the spark plugs back in and reconnect the battery.

Tips: How often should I use an engine compression tester kit?

You should use an engine compression tester regularly during routine maintenance or whenever you notice signs of engine performance issues, such as rough idling, poor acceleration, or starting difficulties. It’s also a good idea to check compression when:

- Your vehicle has high mileage or is aging.

- You experience a noticeable loss of engine power.

- You’re performing engine repairs or overhauls.

- You want to diagnose issues after repairs, such as replacing piston rings or valves.

As a general rule, checking the compression every 30,000 to 50,000 miles is a good preventive measure, but you can also use it whenever you suspect engine problems.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.

The whole preparation was completed, and the spark holes in the machine were installed, and the operation was imaginary. It was written in writing, and most of the time, it was not sealed properly. --- It was 45 years since the equipment was completed, and it was also preserved when it died. Afterwards, the operation was completed, the power was successfully restored, the cutting machine was installed, and the repair was not completed. When the time comes, you can get the hang of it, and it's not possible to use force. The chiropractic performance is relatively high, the home is equipped with a small moving machine, and it is used for troubleshooting in case of emergency clearance!

The whole preparation was completed, and the spark holes in the machine were installed, and the operation was imaginary. It was written in writing, and most of the time, it was not sealed properly. --- It was 45 years since the equipment was completed, and it was also preserved when it died. Afterwards, the operation was completed, the power was successfully restored, the cutting machine was installed, and the repair was not completed. When the time comes, you can get the hang of it, and it's not possible to use force. The chiropractic performance is relatively high, the home is equipped with a small moving machine, and it is used for troubleshooting in case of emergency clearance!