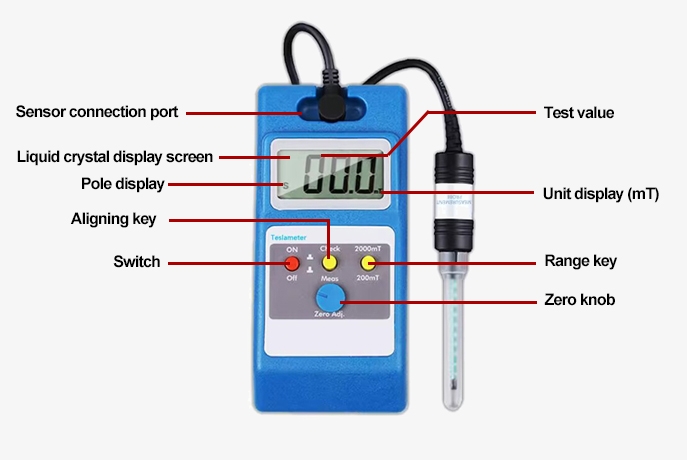

SISCO hand-held LCD EMF radiation detector is designed to offer a fast, dependable, and user-friendly method for measuring. Electromagnetic field radiation detector is lightweight and easy to operate, widely used in home inspection, workplace safety assessment, and by individual concerned about potential health effects of EMF exposure.

Durable Design with Enhanced Usability Features

- Electromagnetic field radiation detector adopts ABS material case, wear-resistant and drop-resistant.

- N pole and S pole display during measurement.

- EMF radiation detector screen adopts an elevation design combined with ergonomics to make the screen display clearer and more convenient for users to read.

Advanced Magnetic Field Detection

- The sensor connection port uses a card slot design to prevent the sensor from loosening and falling off.

- The sensors made by the Hall Effect principle are available in two types: transverse and axial. Choose or purchase them according to your needs.

Ultra-Long Battery Life

- The snap-on spring battery compartment is easy to load and unload.

- Voltage regulator can be used under the condition of mains power.

- The power supply of EMF field detector is 4 AA batteries, which can work continuously for more than 100 hours.

Applications

A digital electromagnetic field (EMF) detector is essential in various fields. In geological exploration, it identifies mineral deposits by detecting anomalies in the Earth's magnetic field. In metal processing, it monitors machinery for faults. Physical experiments use EMF detectors to study electromagnetic phenomena, while electronic engineering relies on them for circuit design, testing, and ensuring compliance with electromagnetic compatibility standards. Overall, EMF detectors are crucial for ensuring safety, efficiency, and accuracy in these diverse applications.

Metal Processing

Physical Experiments

Electronic Engineering

Geological Exploration

| Model | SISCO-EFD-WT10A |

| Measuring Range | 0~200mT~2000mT |

| Basic Error | Level 2: ±2%, (>1000mT) |

| Resolution | 0.1mT / 1mT |

| Sensitivity ((DC) | 0.01mT / 1mT |

| Display Units | mT |

| Measurable Magnetic Field | DC only |

| Relative Temperature | 0°C~50°C |

| Operating Temperature | 5°C~40°C |

| Relative Humidity | 20~80% (no frost) |

| Power Supply | 4*AA batteries |

| Display | LCD: N,S display |

| Probe | Horizontal hall probe (line length 80cm) |

| Weight | 450g (including battery and test line) |

Details

Packing List

- 1 x Electromagnetic field detector

- 1 x Box

- 1 x Charger

- 1 x Probe

- 1 x User manual

- 4 x Battery

Q1: What causes high EMF in a house?

A1: High levels of electromagnetic fields (EMF) in a house can stem from various sources. Common culprits include proximity to power lines, electrical appliances (especially those with motors or transformers), wiring errors, and the use of wireless devices such as Wi-Fi routers and cell phones. Power lines near or running through a property can emit significant EMF, especially if they carry high voltage. Electrical appliances like refrigerators, hairdryers, and microwave ovens can also generate strong EMF fields, particularly when in use or if they have faulty wiring. Additionally, improper grounding or wiring errors within the home's electrical system can create EMF hotspots.

Q2: How to calibrate an electromagnetic field detector?

A2: To calibrate an electromagnetic field detector, start by consulting the manufacturer's instructions as different models may have specific procedures. Use a known and stable calibration source, such as a reference EMF generator or a Helmholtz coil, in a controlled environment free from external interference. Allow the meter to warm up as recommended, then perform zero calibration in an EMF-free setting. Place the meter at a specified distance from the calibration source, activate the source to emit a known EMF level, and adjust the meter’s reading to match this level using the calibration controls. Verify accuracy by measuring other known EMF levels and document the process, including any adjustments made. Follow the manufacturer's recalibration schedule to maintain accuracy.

Q3: What types of EMF can an EMF meter measure?

A3: An EMF meter can measure various types of electromagnetic fields, primarily categorized into low-frequency and high-frequency EMFs. Low-frequency EMFs are typically generated by power lines, electrical wiring, and household appliances, such as refrigerators, microwaves, and hair dryers. High-frequency EMFs, on the other hand, are emitted by wireless devices like Wi-Fi routers, cell phones, and other RF (radio frequency) transmitting devices. Some advanced EMF detectors can measure both types, providing a comprehensive assessment of the electromagnetic environment in a given area.

Tips: how does an EMF detector work?

An EMF detector works by using its internal sensors to detect electromagnetic fields in the surrounding environment. The working principle involves several steps:

- Signal Detection: The sensors detect electromagnetic fields and convert them into corresponding electrical signals.

- Signal Processing: The internal circuitry receives the sensor signals, amplifies, and filters them to remove noise and retain valid signals.

- Data Conversion: The processed signals are converted into digital signals for further processing and display.

- Display and Storage: The final measurement results are displayed on the device’s screen, usually in units such as milligauss (mG), microtesla (µT), or volts per meter (V/m). Some advanced devices also feature data logging capabilities, allowing the storage of measurement data over time for subsequent analysis.

Additionally, advanced models may include features such as peak hold (recording the maximum detected value), sound or visual alarms (triggered when high EMF levels are detected), and data export capabilities (transmitting data via USB or wirelessly).

Through these processes, EMF detectors can provide accurate, real-time electromagnetic field measurements, offering valuable data support for various applications.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.