Built for rugged industrial environments, this handheld digital loop calibrator features an IP65 enclosure rating, meaning it is dust-tight and waterproof, suitable for harsh plant conditions. DC voltage, DC current can be measured, internal 24V loop-powered. Its portability makes it convenient for on-site diagnostics and maintenance.

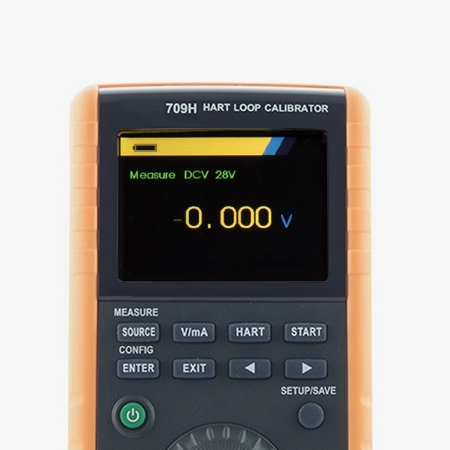

3.2 Inch TFT Color Display

- TFT color display offers higher resolution than ordinary LCD screen, providing clearer, sharper readings. Users can easily view complex data, reducing the likelihood of misreading values, which is critical in calibration tasks.

- TFT display is robust and can withstand industrial environments. It is less prone to damage from vibrations or impacts. Additionally, TFT often consume less power, which extends the life of the handheld loop calibrator.

- Unlike conventional display, TFT screen offers wide viewing angles without color distortion or contrast loss.

ABS Shell & IP65 Protection Level

- Compared with metal material, ABS is significantly lighter. A loop calibrator with an ABS shell is easier to carry, especially for technicians who need to perform on-site calibration for long periods.

- ABS material has excellent toughness and impact resistance. In real-world calibration work, a loop calibrator is often used in demanding environments. Accidental drops, knocks, or vibrations are common. ABS shell can effectively absorb shocks and reduce damage to internal electronic components.

- The sealed enclosure required for IP65 protection also improves mechanical strength. The instrument is better protected against accidental splashes, dirt, and daily wear during transport and on-site use. Components are shielded from corrosion, contamination, and moisture damage.

Applications

SISCO's loop calibrator is widely used in industrial process control. In the oil and gas, petrochemical, and chemical processing industries, it ensures accurate signal measurement and loop troubleshooting. Additionally, loop calibrator is essential in instrument maintenance, field commissioning, and quality assurance for industrial instrumentation systems.

Power Industry

Automation Industry

Laboratory

Petrochemical Industry

| Model | SISCO-LC-709H | |

| Display | 3.2-inch TFT color display | |

| Power Supply | 4*1.5V AA battery (not included) | |

| Operating Condition | Temperature: 0℃~50℃; humidity:≤80%RH | |

| Storage Condition | Temperature: -25℃~60℃; humidity:≤90%RH | |

| Protection Level | IP65 | |

| Dimension | 206*97*60mm | |

| Weight | About 600g | |

| Input Function | Range/ Measurement Range | Resolution/ Accuracy |

| DC Voltage | 28V; -2.000~28.000V | 1mV; 0.01+0.01 |

| DC Current | 30mA; -4.000~33.000mA | 1μA; 0.01+0.01 |

| Loop Current | 24V; / | /; 10% |

Dimension:

Q1: What is a loop calibrator?

A1: A loop calibrator is a precision instrument. It can measure DC voltage, DC current and loop current. It is portable, often handheld, and designed for field use, making it essential tools for maintaining reliable industrial systems.

Q2: What industries commonly use loop calibrator?

A2: Loop calibrator is widely used across industries that rely on precise process control and instrumentation. Common sectors include oil and gas, chemical and petrochemical plants, power generation, water and wastewater treatment, and pharmaceutical manufacturing.

Q3: How to maintain a digital loop calibrator?

A3: Always store it in a clean, dry, and temperature-controlled environment to prevent moisture or dust damage. Regularly check the battery and replace it when low to avoid measurement errors. Clean the device and test leads with a soft, dry cloth; avoid solvents that may damage components.

Tips: What temperature range can this handheld loop calibrator operate in?

This handheld loop calibrator is designed to operate reliably within a temperature range of 0℃ to 50°C. For optimal performance and to ensure the longevity of the device, it is recommended to use it in moderate conditions, ideally between 10℃ and 40℃. Avoid exposing the calibrator to extreme heat or cold, as operating near the upper or lower limits of its range may affect measurement accuracy or cause potential damage.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.