Testing height gauges is a critical step in ensuring their accuracy and reliability, especially in industrial, manufacturing, and scientific applications. A height gauge is an instrument used to measure the height or position of an object, and it can work on different principles such as mechanical triggering, laser measurement, or ultrasonic measurement to meet different measurement needs. sisco shop will detail how to conduct a height gauge test, from the preparation phase to the testing steps and considerations to ensure that accurate and reliable measurements are obtained.

Installation of the Height Gauge

First, choose an appropriate location to mount the height gauge. This location should be flat, stable, and away from sources of vibration and interference. Ensure that the measurement area is clean and that the surface of the target object is free of dust, oil, or foreign matter, which may affect the accuracy of the measurement. Ensure that the chosen location can accommodate the height gauge without being disturbed by external factors such as temperature variations, humidity, etc. In addition, ensure that the work area is adequate so that the operator can easily access and operate the height gauge.

The accuracy of the height gauge is closely related to its leveling. Use a spirit level or leveling scale to ensure that the height gauge is installed horizontally. Incorrect horizontal alignment can lead to measurement errors. Securely fasten the height gauge in the selected position. This usually involves securing the height gauge to a workbench, floor, or other support structure to ensure that it does not move or wobble during measurements.

Ensuring the stability of the height gauge is essential for accurate measurements. If the height gauge requires a power supply, ensure that the power cord is properly connected and that the power supply is stable and reliable. Any power failure may affect the accuracy of the measurement. Perform a calibration of the height gauge before taking actual measurements. The calibration procedure is usually provided by the manufacturer and the manufacturer's guidelines are followed to ensure accurate measurements.

Test Preparation Steps

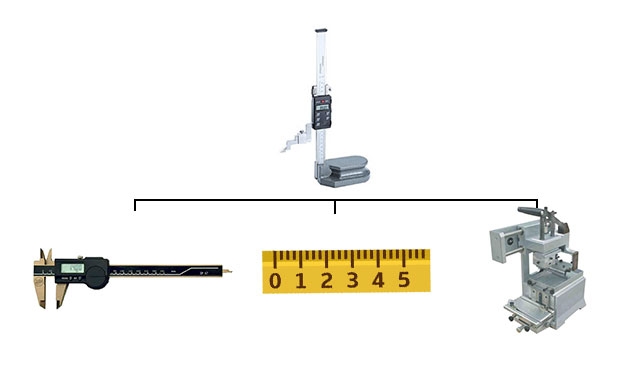

Before performing the test, you first need to define the purpose of the test and the required measurement parameters. It is important to understand the height range to be measured, the accuracy requirements, and the units of measurement. This will help in selecting the appropriate height scale and test method. According to the purpose of the test, select the appropriate type and size of the height gauge. Different height gauges have different characteristics and measurement ranges, so it is necessary to select a height gauge that matches the test requirements. The surface of the target object should be clean and free of dust or debris. Dust or debris may affect the accuracy of the measurement results. When necessary, use a cleaning tool to clean the surface of the target object.

Before testing, make sure the height gauge has been calibrated. Calibration ensures that the instrument provides accurate measurements. Calibration is usually carried out by the manufacturer or a professional organization and needs to be done periodically to maintain accuracy. Ensure that all necessary measuring tools and aids (e.g. calipers, rulers, fixtures, etc.) are in place. These tools can be used to calibrate height gauges, assist in the measurement process, or verify results. Consider factors of the test environment such as temperature, humidity, and air pressure. These factors may affect the measurement results, so environmental corrections need to be made or measures taken to minimize their effects. Relevant safety protocols need to be followed in test preparation. Ensure that the test area is safe from injury or danger to instruments or testers. Develop a test plan that defines the process, schedule, and people involved in the test. This helps to ensure that the testing process is organized and stays on schedule.

Steps for Testing the Height Gauge

- Installation and Preparation: Before conducting an altimeter test, you need to ensure that it is properly installed and in working order. This includes checking the power connections, leveling the altimeter, cleaning the probe or sensor, and calibrating the probe for specific test requirements.

- Selecting the Right Probe or Sensor: Select the right probe or sensor for the specific needs of the test. Different applications may require different types of probes, such as mechanical triggers, laser or ultrasonic sensors. Ensure that the selected probe adapts to the height range and accuracy requirements of the test.

- Positioning the Target Object: Place the target object under the height gauge and make sure it is properly aligned with the probe or sensor. Adjust the position of the target object so that it is within the measurement range of the probe.

- Trigger Measurement: Trigger the measurement process depending on how the height gauge is operated. This may involve pressing the measurement button, activating the laser, or sending an ultrasonic signal. Ensure that the measurement process proceeds smoothly and wait for the measurement results to appear.

- Record the Measurement Result: The excellent height gauge will automatically measure the height of the target object and display the result on the height gauge's display. Record the measurement results, including any additional information such as time stamps or location information. This is for tracking and analyzing the measurement data.

- Data Analysis and Processing: The measurement data is further analyzed and processed according to the purpose and requirements of the test. This may include calculating averages, standard deviations, comparisons with other measurements, or generating graphs and reports.

Precautions

- Calibration: Calibrate the height gauge periodically to ensure its measurement accuracy. Calibration procedures should follow the guidelines provided by the manufacturer.

Consider the effect of environmental factors, such as temperature, humidity, and barometric pressure, on measurement results. Perform environmental calibration as needed. - Avoid Vibration: Ensure that the height gauge or target object is not subjected to vibration or shock during testing, which may result in inaccurate measurement results.

- Avoid Interference: Ensure that the measurement area is free from sources of interference, such as strong light or electromagnetic radiation, which may interfere with the height gauge's sensors.

- Operating Instructions: The operator should familiarize himself with the instructions for the use of the height gauge and follow the manufacturer's recommendations. Observe safety procedures to avoid accidents and injuries.

By following the installation, test preparation, test procedures, and precautions outlined above, the accuracy and reliability of the height gauge can be ensured to meet the measurement needs of a variety of applications. Height gauges play an important role in industry, scientific research, and manufacturing, where accurate measurements are essential for product quality control and research.