The wireless dynamometer comes with a remote control with a minimum control distance of 15m. The LCD screen displays the kg/lb/N/kN unit switching, and the programmable setpoint is available for safety and warning applications. These industrial wireless dynamometers can be used in logistics transportation, industrial construction, and other weighing applications.

LCD Display screen, microprocessor control

- The digital dynamometer comes with a high-definition display screen, providing a clear and intuitive digital display for easy real-time reading of weight data.

- All functions and units are clearly displayed on the backlit LCD screen, showing kilograms (kg), pounds (lb), Newtons (N), and kilonewtons (kN).

- The wireless dynamometer has a range of 1-200t and uses microprocessor control to ensure accuracy. Parameter setting and calibration are easily performed via remote control.

Wireless handheld device, wireless communication

- The wireless force dynamometer boasts excellent wear resistance and corrosion resistance. It features ring hooks at both ends for easy connection to lifting equipment, adapting to various lifting and weighing operations.

- The industrial dynamometer is equipped with a compact remote control, allowing users to easily operate it remotely, adjust measurement parameters, or read real-time data.

- The electric dynamometer is made of aluminum alloy and can be programmed for safety warnings or extreme weighing settings. The overall design emphasizes practicality and convenience, ensuring stable operation even in harsh environments.

Application

Wireless digital dynamometers with an industrial shackle are typically used to measure the weight of an object or the tensile force applied to it. They are widely used in industries such as manufacturing, logistics, water conservancy inspection, mining, and warehousing for the accurate measurement of weight.

Port Logistics

Mining

Water Conservancy

Industrial Construction

| Model | SISCO-GWD400 |

| Display | 25mm (1") 5digits LCD with backlight |

| Power On Zero Range | 20% F.S. |

| Manual Zero Range | 4% F.S. |

| Tare Range | 100% F.S. |

| Stable Time | ≤5 seconds |

| Overload Indication | 100% F.S. + 9e |

| Max. Safety Load | 125% F.S. |

| Ultimate Load | 400% F.S. |

| Dynamometer Battery | LR6 (AA) size alkaline batteries. 1.5Vx3 |

| Remote control Battery | LR6 (AAA)"size alkaline batteries. 1.5Vx2 |

| Operating Temp | -10°C~ + 40°C |

| Operating Humidity | ≤85% RH under 20°C |

| Remote Controller Distance | Min. 15m |

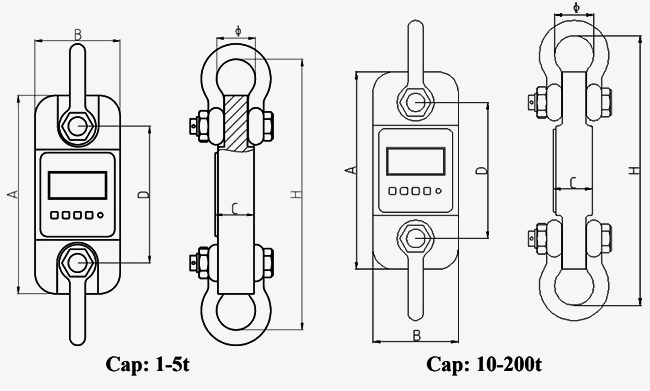

| Model | Capacity | Div(kg) | A(mm) | B(mm) | C(mm) | D(mm) | φ(mm) | H(mm) | Material |

| GWD400-1t | 1 | 0.5kg | 245 | 112 | 37 | 190 | 43 | 335 | Aluminum |

| GWD400-2t | 2 | 1kg | 260 | 123 | 37 | 195 | 51 | 365 | Aluminum |

| GWD400-3t | 3 | 1kg | 260 | 123 | 37 | 195 | 51 | 365 | Aluminum |

| GWD400-5t | 5 | 2kg | 285 | 123 | 57 | 210 | 58 | 405 | Aluminum |

| GWD400-10t | 10 | 5kg | 320 | 120 | 57 | 230 | 92 | 535 | Alloy Steel |

| GWD400-20t | 20 | 10kg | 375 | 128 | 74 | 260 | 127 | 660 | Alloy Steel |

| GWD400-30t | 30 | 10kg | 420 | 138 | 82 | 280 | 146 | 740 | Alloy Steel |

| GWD400-50t | 50 | 20kg | 465 | 150 | 104 | 305 | 184 | 930 | Alloy Steel |

| GWD400-100t | 100 | 50kg | 570 | 190 | 132 | 366 | 229 | 1230 | Alloy Steel |

| GWD400-200t | 200 | 100kg | 720 | 265 | 183 | 440 | 280 | 1362 | Alloy Steel |

Digital Wireless Dynamometer 200 ton

| Model | Capacity(kg) | Min.Weigh(kg) | Division(kg) | Total counts (n) |

| GWD400-01 | 1000 | 10 | 0.5 | 2000 |

| GWD400-02 | 2000 | 20 | 1 | 2000 |

| GWD400-03 | 3000 | 20 | 1 | 3000 |

| GWD400-05 | 5000 | 40 | 2 | 2500 |

| GWD400-10 | 10000 | 100 | 5 | 2000 |

| GWD400-20 | 20000 | 200 | 10 | 2000 |

| GWD400-30 | 30000 | 200 | 10 | 3000 |

| GWD400-50 | 50000 | 400 | 20 | 2500 |

| GWD400-100 | 100000 | 1000 | 50 | 2000 |

| GWD400-200 | 200000 | 2000 | 100 | 2000 |

Q1: What is a wireless industrial dynamometer?

A1: A wireless dynamometer is a high-precision electronic measuring device used to measure the magnitude of forces (such as tension, compression, or weight) on an object. It combines a traditional strain gauge force sensor with wireless data transmission technology, enabling long-distance real-time measurement and monitoring without a signal cable connection. This digital dynamometer typically consists of a force sensor body, a wireless transmitter module, and a receiving display terminal or host computer system, suitable for various industrial applications requiring load monitoring.

Q2: How does a wireless industrial dynamometer works?

A2: When the object being measured experiences tension or compression, the strain gauge inside the force gauge undergoes a slight deformation, causing a change in resistance. The internal circuitry converts this change into an electrical signal, which is amplified, processed, and then converted into force data. This data is then transmitted to the receiving terminal via a wireless module (such as Bluetooth, Wi-Fi, LoRa, or 2.4GHz). Users can view the force value in real time on a display instrument, computer, or mobile device, and can also perform data storage, alarm functions, or remote monitoring.

Q3: What are the main functions of wireless industrial dynamometer?

A3: Wireless crane dynamometers are widely used in hoisting, bridge inspection, structural stress monitoring, port logistics, oil and mining, scientific research and experimentation, and other fields. They can monitor load changes in real time, prevent equipment overload, and ensure construction and production safety. Simultaneously, crane weighing dynamometer can record and analyze stress data, providing reliable data for engineering inspection, equipment maintenance, and quality control. Combined with IoT technology, industrial dynamometers can also achieve multi-point monitoring and cloud data management, contributing to the digital and intelligent development of industry.

Tips: What is the difference between a dynamometer and a crane scale?

A dynamometer is mainly used to measure tensile force, tension, or the magnitude of applied force. It is commonly used in mechanical testing, structural stress monitoring, and industrial tensile testing, emphasizing force change and testing accuracy. A crane scale, on the other hand, is primarily used to weigh objects during lifting operations, focusing on the weighing result itself. Although they may share some similarities in appearance and usage, a digital dynamometer emphasizes "force measurement," while a crane scale emphasizes "weight measurement," differing in application purpose and design focus.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.