This liquid-filled pressure gauge is primarily used to measure pulsating pressures, such as those found in fracturing and cementing equipment, mud pumps, and risers in oil production. It can also be used to measure static pressure, accommodating a wide range of pressure measurement needs.

Note: If you need other sizes, please contact customer service.

Accurately Measuring High-Frequency Pulsating Pressure

- This professional tire pressure gauge's core function is to accurately measure high-frequency pulsating pressures, such as those generated by fracturing pumps, cementing equipment, and mud pumps. Its internal diaphragm assembly and damping mechanism effectively suppress pressure pulsations, ensuring a smooth needle indication and easy reading of average pressure values.

- This precision pressure gauge utilizes a liquid-filled design, with methyl silicone oil inside the gauge head as a damping medium to prevent needle jump under high vibration conditions and enhance the instrument's service life and reliability in high-vibration environments.

- The mud pump pressure gauge utilizes an isolated measurement principle. The measured medium (such as mud or cement slurry) does not enter the gauge, but rather transmits pressure through the diaphragm. This design fundamentally prevents clogging and wear on the gauge caused by high-viscosity, high-granularity, and easily solidifying media.

Graded Accuracy Adapts to Various Scenarios

- The conventional range (0-25 MPa/0-3000 psi) offers Class 2.5 accuracy, suitable for routine monitoring; the high-pressure range (40-160 MPa/6000-10000 psi) offers Class 1.6 accuracy, suitable for precision applications.

- The gauge uses a flange mounting method and should be mounted vertically without additional buffers. A bleed screw is located on the top of the gauge body, serving as a safety relief vent to prevent accidents caused by excessive pressure.

- The gauge features reliable sealing and anti-corrosion treatment, making it waterproof and moisture-resistant, fully meeting the requirements of long-term operation in harsh environments such as open air and high humidity.

Applications

In industrial production, a pressure meter ensures equipment safety and process stability; in public services, a pressure gauge maintains daily operation and safe use; in the medical and health field, a pressure test gauge assists in diagnosis and treatment; in scientific research and high-end manufacturing, a pressure reader supports research and development and reliable equipment operation.

Public Services

Healthcare

High-End Manufacturing

Industrial Production

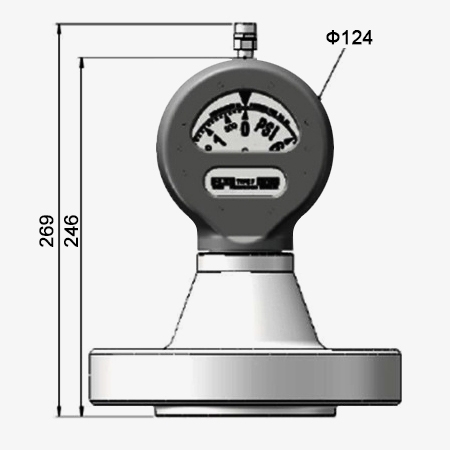

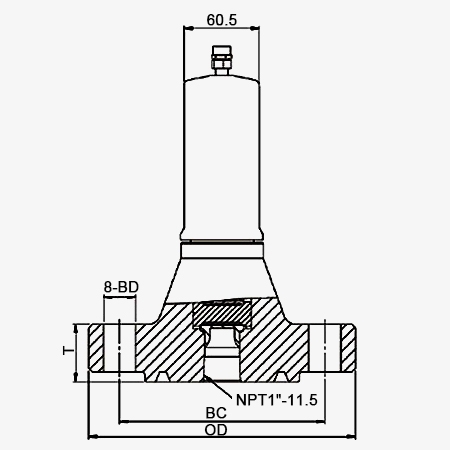

| Model | SISCO-PG-F130 | ||

| Nominal Bore Diameter | 2-1/16 in | ||

| Flange Pressure | 5000psi | ||

| Outer Diameter (OD) | 215mm | ||

| Flange Thickness (T) | 46.1mm | ||

| Bolt Hole Diameter (BD) | 26mm | ||

| Bolt Hole Diameter Distribution Diameter (BC) | 165.1mm | ||

| Polishing Range (MPa) | 0~6, 0~10, 0~16, 0~25 | Accuracy Grade | 2.5 |

| 0~40, 0~60, 0~80, 0~100, 0~120, 0~160 | Accuracy Grade | 1.65 | |

| Operating Temperature | -22℃~55℃ | ||

| Packaged Weight | 15kg | ||

Structure Diagram

Q1: What is a digital pressure gauge?

A1: A digital pressure gauge is an instrument that measures and displays pressure readings electronically using a digital display. It typically offers higher accuracy and ease of use compared to analog pressure gauges.

Q2: How does a digital pressure gauge work?

A2: A digital pressure gauge measures pressure using a sensor that converts pressure into an electrical signal. This signal is amplified, converted from analog to digital, processed by a microprocessor, and then displayed on a digital screen. The result is an accurate, real-time pressure reading.

Q3: What is a pressure gauge used for?

A3: Yes, a digital pressure gauge is generally more accurate than a mechanical pressure gauge, as it offers higher precision, better resolution, and easier readability due to its electronic components and digital display.

Tips: How to tell if your pressure gauge is accurate?

Check: Is it used within the 1/3 to 2/3 range, ensuring it's within the specified range? Check whether the reading error meets the specified accuracy. It's recommended to install the gauge vertically, avoid over-range operation, and check the readings regularly. The silicone oil inside the gauge is not replaceable. During installation, avoid moving the gauge marked "NO WRENCH HERE" to prevent structural damage. Following usage and maintenance instructions can significantly extend the life of the gauge and ensure accurate readings and safe operation during field operations.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.

Upon receiving the pressure gauge, its appearance was first inspected. The dial was clear, the pointer was flexible, and the connector material appeared durable. Installation was relatively simple, fitting well with the existing hydraulic system's threaded interface; only the sealing ring needed attention. During actual commissioning, the pressure gauge's response speed was satisfactory, reflecting real-time changes in pump station pressure. The pointer moved smoothly without any jamming or jumping.