SISCO truck axle weighing scale is one of the ultrasonicinstruments, and it is also a must-have for protecting the car. The indicator can be equipped with 4 to 16 weighing platform pads. This portable axle weight scale is suitable for static weighing, which is mainly used in automobile/aircraft production inspection, low-value vehicle cargo measurement, portable mobile truck scales, static weighing platforms, etc.

The Single-Board Pad is Lightweight and Easy to Carry

- Lightweight Single Pads: Each weighing pad is designed with a compact, lightweight structure, making it easy to carry and deploy in the field without heavy lifting equipment.

- Portable & Easy to Transport: The slim, low-profile design and built-in handles allow operators to quickly move and set up the scale at different locations, ideal for mobile weighing operations.

- Durable Aluminum Alloy Construction: The weighing pads are made of high-strength aluminum alloy, offering both light weight and excellent durability for long-term outdoor use.

- Quick Setup & Operation: The scale can be easily placed on any flat surface, requiring no foundation or complex installation, simply connect and start weighing.

- Compact Storage Design: When not in use, the pads can be stacked or stored in a carrying case, saving space and improving work efficiency.

The Truck Axle Scale Built-in Printer

- Built-in Thermal Printer: The portable axle scale comes equipped with a high-speed thermal printer, allowing users to print weighing results instantly without the need for external devices.

- On-site Data Recording: Operators can quickly generate weight tickets on-site, improving efficiency for logistics, transport, and inspection operations.

- Clear & Durable Printouts: The built-in printer produces clear, easy-to-read weight data, including axle weight, total weight, and date/time information.

- Convenient Data Management: Printed reports can be used for record-keeping, compliance documentation, or cross-checking with digital data stored in the system.

- User-friendly Design: The printer is seamlessly integrated into the indicator housing, ensuring compact structure, easy maintenance, and reliable performance in field conditions.

Applications

SISCO weighing indicators are widely used for accurate weight measurement in various industries. They are essential in warehouses for inventory management, in supermarkets for weighing products and pricing, in logistics and transportation to prevent overloading, and at ports for weighing containers and ensuring safe cargo handling. These devices enhance efficiency and precision across these applications.

Logistics and Transportation

Warehouse

Wharf

Supermarket

| Model | SISCO-WI-GPWA02-1-500 | SISCO-WI-GPWA02-1-720 | SISCO-WI-GPWA02-1-900 |

| Weighing Pad Specs | |||

| Pad Size | 500*400*40 mm | 720*450*40 mm | 900*500*40 mm |

| Slope Size | 500*300 mm | 720*330 mm | 900*350 mm |

| Single Pad Maximum Range | 10t | 15t | 25t |

| Accuracy | Dynamic:5% | ||

| Tatic:0.1%~0.3% | |||

| Sensor Structure | There are four or six spoke type sensor at the bottom | ||

| Safety Overload Range | 120% | ||

| Limit Overload Range | 150% | ||

| Portable Axle cale | |||

| Function | 1. Only static measurement; | ||

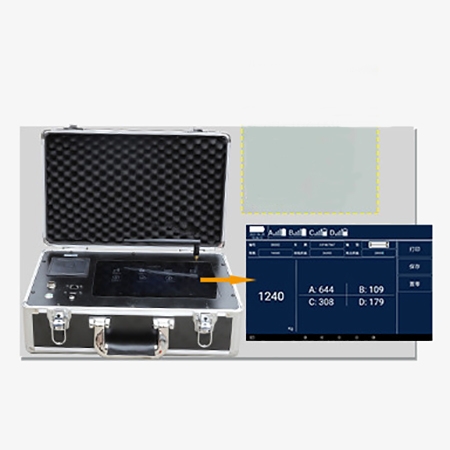

| 2. Adopt a 10.1-inch touch color screen; | |||

| 3. can connect 4 to 12 pads in static mode; | |||

| 4. You can use touch mode and wireless mouse mode to input and operate; | |||

| 5. Statistical analysis software is convenient for statistics, records and queries. | |||

| Specifcation | 1. Division value: 5, 10, 20kg optional; | ||

| 2. Working temperature: -20~80℃; | |||

| 3. Power supply: DC11.1V lithium battery; | |||

| 4. Data output: RS232 and USB; | |||

| 5. Printer: built-in needle type high speed energy-saving printer; 200,000 pieces of vehicle information can be stored inside the indicator | |||

Q1: What is a weighing indicator?

A1: A weighing indicator is a device used in conjunction with weighing scales or load cells to display and process weight measurements. It receives electrical signals from the load cells, converts them into readable weight values, and displays the information on a screen. Depending on the model, weighing indicators can offer additional features like data storage, connectivity for data transfer, and advanced weighing functions such as tare, counting, and totalizing. They are commonly used in various industries, including logistics, warehousing, retail, manufacturing, and more, to ensure accurate weight readings and efficient process management.

Q2: Can weighing indicators be used with different types of scales?

A2: Weighing indicators can be used with a variety of scales, making them versatile tools in numerous industries. They are compatible with different types of scales, such as platform scales for heavy-duty industrial use, bench scales for smaller applications like retail or laboratories, floor scales for bulk weighing in warehouses, and weighbridges for weighing large vehicles in logistics and transportation. Additionally, they can be used with hopper and tank scales in manufacturing and crane scales for suspended loads in construction or shipping. This flexibility allows Weighing Indicators to meet diverse weighing needs across multiple sectors.

Q3: How do weighing indicators communicate with other devices?

A3: Many weighing indicators support communication protocols like RS232, RS485, Ethernet, USB, or wireless options. This allows them to connect to computers, printers, or control systems for data logging or remote monitoring.

Tips: Can the portable axle scale be used on uneven or rough ground?

While the portable axle scale is designed for field use, it performs best when placed on a flat, solid, and level surface such as concrete or asphalt. Uneven or rough ground may cause slight measurement deviations because it affects how the vehicle’s weight is distributed across the pads.

For outdoor or temporary weighing sites where a perfectly level surface isn’t available, leveling mats or rubber ramps are recommended to provide a more stable base and improve accuracy. Some models are equipped with adjustable feet or built-in leveling functions to help compensate for minor ground irregularities.

In general, for the most reliable weighing results, always ensure that the pads are stable, the tires are evenly positioned, and the vehicle is completely stopped before recording the weight.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.

Portable Axle Scale User Manual

Portable Axle Scale User Manual