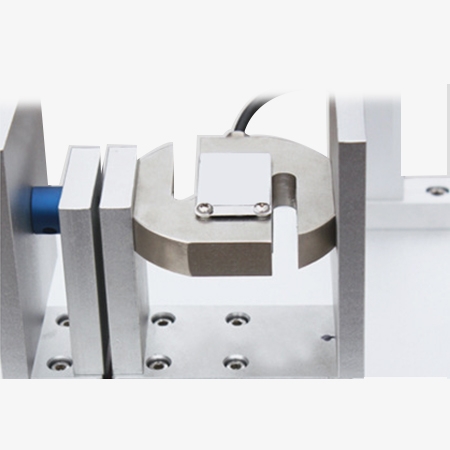

The tensile compression testing machine integrates high-precision measurement with a height-adjustable testing mechanism. Its dual-sided expansion stroke allows for precise positioning of the test workpiece, flexibly adapting to the testing needs of various headphone sizes.

Dual-sided Expansion Design

- The expansion stroke range is 0-260mm, and it can move bilaterally, making the testing process more flexible. One testing station can simultaneously test the clamping force of two headphones, effectively improving testing efficiency.

- The equipment uses a high-precision sensor, with a force value display accuracy of 0.0001kg and an error of less than ±1%, meeting stringent industrial testing standards and ensuring accurate assessment of headphone clamping force.

- The earcup fixing plate has a diameter of 100mm and features XY axis markings, helping operators accurately position the earcups and ensuring consistent force application points in each test, avoiding distorted test results due to positioning deviations.

Multi-force Unit Compatibility

- The LCD screen can display multiple force units, such as kg, N, and LB, allowing users to select the appropriate unit for testing and recording based on different needs.

- The electrostatically coated enclosure has a robust structure, maintaining stable performance during long-term, high-frequency testing, meeting the durability and operational safety requirements of industrial environments.

- The LCD screen displays test data in real time, and parameters are set using membrane keys. Operation is simple and intuitive, allowing for quick result reading and comparison of multiple tests.

Applications

A tensile tester is a commonly used material testing equipment used to evaluate the mechanical properties of materials under tension. A tensile testing machine can be used in the research and development of new materials to test their tensile strength, yield strength, elastic modulus, elongation at break, and other mechanical properties. In various manufacturing industries, such as metal processing, plastic molding, rubber manufacturing, fiber reinforced composite material production, etc, the performance of raw materials and finished products. It can also be used to test the mechanical properties of products such as medical implants and surgical instruments to ensure their safety and functionality during use. It is used to test the tensile strength and elongation of textile and clothing materials, and can also ensure the comfort and durability of the product.

Electronic Appliances

Industrial Plastics

Laboratory

Auto Parts

| Model | SISCO-TT-NJ02 |

| Test Station | One set |

| Force Measurement Range | 5kg |

| Force Display | 0.0001kg, Less than ±1% |

| Tension Display | LCD digital display |

| Force Unit | kg, N, LB |

| Force Sensor | 5kg high-precision sensor |

| Earm Cover Fixing Plate | 100mm diameter, with XY axis scale |

| Intermediate Guide Rod | 300mm height |

| Extension Stroke | 0-260mm (dual-sided movable) |

| Stroke Adjustment | Slider type (left and right movement) |

| Power Supply | AC 220V, 50Hz |

| Size | 600mm×500mm×880mm |

| Weight | 115kg |

Q1: Does the Test Speed of the Tensile Tester Affect the Test Results?

A1: The test speed of the tensile tester has a significant effect on the test results. Test speed refers to the rate at which the specimen is stretched during the tensile test, usually expressed in millimeters per minute (mm/min) or strain rate (such as percentage change per second).

Q2: How to Choose the Appropriate Test Speed Based on Material Properties?

A2: When choosing the appropriate test speed for material testing, multiple factors need to be considered, including the material's mechanical properties, strain rate sensitivity, test standards, and experimental purpose.

Q3: How to Use a Tensile Tester?

A3: First, prepare the machine to ensure that the machine is in good working condition and check whether all parts are intact, Install the specimen correctly in the fixture of the tester. Set the initial height of the pendulum according to the test standard to ensure that the pendulum has enough energy for the test when it is released. Release the pendulum and let it fall freely and hit the specimen. After the pendulum hits the specimen, record the final position of the pendulum or record the data through the automatic measurement system of the testing machine.

Tips: What to do if the sample slips or breaks at the clamp during testing?

First, check if the clamp is suitable for the material (for soft materials, replace with a clamp with anti-slip texture; for hard materials, ensure the clamping surface is flat). Second, adjust the clamping force to avoid slipping due to excessive looseness or breaking due to excessive tightness. If the problem persists, you can place anti-slip material (such as rubber sheets or sandpaper, taking care not to affect the test results) on the contact surface between the clamp and the sample, or re-prepare the sample, ensuring the clamping area meets the dimensions requirements and is free of burrs or defects.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.