A thermal gas mass is a type of flow meter that measures the flow rate of gases in a pipeline, it can measure various gases (except the acetylene). The thermal gas mass flow meter has the advantages of small in size, high degree of digitization, convenient installation and accurate measurement.

The thermal mass gas flow meter design with a large LCD backlit display for clearer readings

- The thermal mass flowmeter equipped with a large, high-definition LCD screen, the flow meter provides clear and easy-to-read measurements, allowing operators to effortlessly view and record flow data, especially in dimly lit environments.

- The LCD screen features backlighting, ensuring that readings remain visible and clear even in low-light or nighttime conditions, thereby enhancing operational efficiency and the accuracy of data retrieval.

- The intuitive user interface, combined with the large display, simplifies the setup and operation process, making it easier for users to understand and operate the device while minimizing the chance of errors.

The thermal mass meter design with a waterproof rating

- The flow meter is designed with a robust waterproof rating, ensuring reliable operation even in harsh or wet environments. This makes it suitable for outdoor installations and applications where exposure to moisture is a concern.

- Built with high-quality materials, the meter is resistant to water ingress, protecting its internal components and maintaining accuracy and performance in challenging conditions.

- The waterproof design not only enhances the meter's durability but also extends its lifespan, reducing maintenance requirements and ensuring long-term reliability in various industrial settings.

Application

SISCO flow meter calculates the mass flow rate of the fluid based on the power required to maintain the constant temperature difference. Thermal mass flow meters are commonly used in applications where precise measurement of gas flow is required, such as in biotechnology, medical equipment, scientific research, chemical and petrochemical industries.

Medical Equipment

Scientific Research

Petrochemical Industry

Biotechnology

| Model | SISCO-FM-F2 |

| Measuring Medium | Various gases (Except the acetylene) |

| Pipe Size | 1/2 inch, 2 1/2, 4 inch, 8 inch |

| Working Pressure | 1.6 MPa, 2.5 MPa, 6.3 MPa |

| Measuring Range | 0-152 Nm³/h |

| Velocity | 0.1~100 Nm/s |

| Installation Method | Threaded connection, clamp, plug-in, flange |

| Accuracy | ±1~2.5% |

| Working Temperature | Sensor: -40℃~+220℃ Transmitter: -20℃~+45℃ |

| Working Pressure | Insertion Sensor: medium pressure≤ 1.6MPa Flanged Sensor: medium pressure≤ 1.6MPa For special pressure please contact us |

| Power Supply | 24VDC or 220VAC |

| Response Time | 1s |

| Output | 4-20mA (optoelectronic isolation, maximum load 500Ω), Pulse, RS485 (optoelectronic isolation) and HART |

| Alarm Output | 2 line Relay, Normally Open state, 3A/30V/DC |

| Sensor Type | Standard Insertion, Hot-tapped Insertion and Flanged |

| Construction | Compact and Remote |

| Pipe Material | Carbon steel, stainless steel, plastic, etc |

| Display | 4 lines LCD Mass flow, Volume flow in standard condition, Flow totalizer, Velocity, etc. |

| Protection Class | IP65 |

| Sensor Housing Material | Stainless steel (316) |

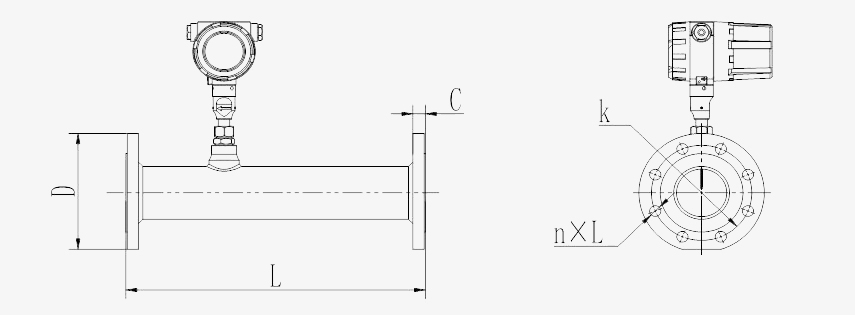

Dimension

| Nominal Diameter (mm) | Flanged Outer Diameter (mm) | Center Hole (mm) | Screw Hole (mm) | Screw Thread | Sealing Face (mm) | Flanged Thickness (mm) | Pipeline Length (mm) | |

| inch | D | k | n*L | d | f | C | L | |

| 1/2 | 95 | 65 | 4*14 | M12 | 46 | 2 | 14 | 200 |

| 2 1/2 | 185 | 145 | 4*18 | M16 | 118 | 2 | 20 | 200 |

| 4 | 220 | 180 | 8*18 | M16 | 156 | 2 | 22 | 200 |

Q1: What is a flow meter?

A1: A flow meter is a device that measures the flow rate or volume of a fluid, such as a liquid or gas, as it moves through a pipe or conduit. It provides real-time data on the amount of fluid passing a specific point, which is crucial for monitoring and controlling industrial processes, ensuring accurate dosing, and optimizing system performance. Flow meters come in various types and technologies, each suited for different applications and fluid properties.

Q2: How often should flow meters be calibrated?

A2: The frequency of flow meter calibration depends on several factors, including:

- Application Requirements: High-precision applications may require more frequent calibration.

- Fluid Type: Corrosive or abrasive fluids may necessitate more regular checks.

- Operating Conditions: Extreme temperatures, pressures, or high flow rates can affect accuracy.

- Manufacturer Recommendations: Follow the guidelines provided by the flow meter manufacturer.

- Regulatory Standards: Some industries have specific calibration requirements.

As a general rule, flow meters are often calibrated annually, but this can vary. It’s also advisable to calibrate whenever there is a significant change in process conditions or if the flow meter shows signs of drift or performance issues.

Q3: What factors can affect flow meter accuracy?

A3: Several factors can affect the accuracy of a flow meter:

- Fluid Properties: Changes in fluid density, viscosity, or temperature can impact accuracy. For instance, varying fluid densities can affect measurement, especially in vortex and electromagnetic flow meters.

- Flow Conditions: Turbulence, flow profile, and pressure drops can influence measurements. Inaccurate readings can occur if the flow is not properly aligned with the meter.

- Installation Issues: Incorrect installation, such as improper pipe alignment or insufficient straight pipe sections before and after the meter, can cause inaccuracies.

- Temperature: Extreme temperatures can affect fluid properties and the meter's components, leading to measurement errors.

- Pressure: Variations in pressure can alter fluid density and viscosity, impacting flow meter accuracy.

Tips: Advantages of using a thermal gas mass flow meter

Thermal gas mass flow meters offer several advantages, making them a popular choice for various applications. Here are the key benefits:

- Direct Mass Flow Measurement: Thermal gas mass flow meters measure the mass flow rate directly, without the need for separate temperature and pressure compensation, simplifying the process and reducing potential errors.

- High Accuracy and Sensitivity: These meters provide highly accurate measurements, especially at low flow rates, where other types of flow meters may struggle. They are sensitive enough to detect even minute changes in gas flow.

- Wide Flow Range: Thermal gas mass flow meters can measure a wide range of flow rates, from very low to moderate, making them versatile for different applications.

- Versatility: They are suitable for a wide variety of gases, including air, nitrogen, hydrogen, natural gas, oxygen, and more. Some models can even measure mixed or dirty gases.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.