A touch screen Leeb hardness tester is a portable device designed to measure the hardness of metals quickly and accurately using the Leeb rebound method. This kind of rebound hardness tester supports conversion of multiple hardness scales, including HL, HRA, HRB, HRC, HB, HV, and HSD. The Leeb hardness tester is lightweight, portable, and versatile, suitable for both field and laboratory use.

Easy to Carry

- Excellent Portability and Convenience. The compact size makes the touch screen Leeb hardness tester easy to carry and operate in different locations. It can be comfortably used with one hand, stored in a toolbox, or carried to field sites without adding extra burden. This is especially useful for on-site inspections and outdoor testing.

- Reduced Fatigue During Long-Term Use. The compact and lightweight design reduces hand fatigue. This is particularly beneficial for inspectors who must perform repeated measurements across multiple parts or workstations in one shift.

Portable Leeb Hardness Tester Equipped With a Touch Screen

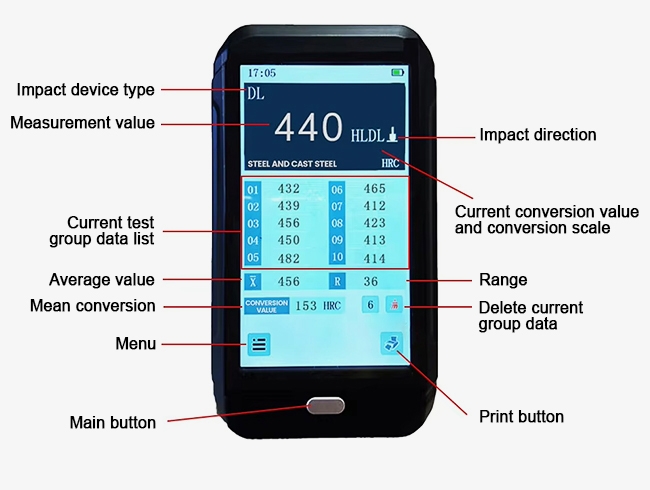

- More Intuitive and User-Friendly Operation. Leeb tester equipped a touch screen greatly improves usability compared with traditional button-operated testers. Operator can navigate menu and select measurement mode.

- Clear and Visualized Data Display. Touch screen models usually feature high-resolution color displays that can show test results more clearly. Measured values, averages, and current test group data list can be displayed at the same time.

Applications

Leeb hardness testers are widely used for on-site hardness testing of large and heavy metal parts. Their primary application is in quality control and maintenance across various industries, including manufacturing, automotive, shipbuilding, and power generation. They are especially useful for testing hard-to-move components like large castings, forgings, shafts, pressure vessels, and welded structures.

Shipbuilding Industry

Manufacturing Industry

Metal Processing

Automotive Industry

| Model | SISCO-HT-BLN-200 |

| Impact Device Type | D, DC, DL, D+15, C, G |

| Conversion Scale | HV, HB, HRA, HRB, HRC, HSD, Mpa |

| Measurement Direction | All directions can be set |

| Accuracy | ±6HL |

| Display | 800*480 TFT LCD (touch screen) |

| Data Storage | 2000 records |

| Data Transmission | USB |

| Printer | Micro wireless printer (optional) |

| Power Supply | 3.7V 1400mAh rechargeable Lithium battery; DC 5V 1A (charging power supply) |

| Indenter Material | Tungsten carbide ball |

| Operating Temperature | Temperature: -10~40°C; humidity: 20%~85% |

| Storage Temperature | Temperature: -30~80°C; humidity: 5%~95% |

| Dimension | 151*85*27mm (main unit) |

| Weight | 255g (main unit), 5.5kg (a whole set) |

Interface Introduction:

Q1: What is Leeb hardness tester?

A1: A Leeb hardness tester is a portable device used to measure the hardness of metals and alloys by the Leeb rebound principle. It operates by releasing a standardized impact body against the test surface and measuring the rebound velocity.

Q2: What does the Leeb hardness value (HL) represent?

A2: The Leeb hardness value (HL) represents a measure of a material's surface hardness based on the rebound principle. It is determined by the Leeb hardness test, where a small, hard impact body is propelled against the test material’s surface. The device measures the velocity of the impact body both before and after striking the surface. The Leeb hardness value is calculated from the ratio of the rebound velocity to the impact velocity, multiplied by 1000, and is expressed in HL (Hardness Leeb) units.

Q3: What materials can be tested using a Leeb hardness tester?

A3: A Leeb hardness meter is primarily used to measure the hardness of metallic materials. It is suitable for testing metals such as steel, cast iron, cast steel, stainless steel, and various alloys.

Tips: Can the touch screen Leeb hardness tester be used in high-temperature environments?

A touch screen Leeb hardness tester can be used in moderate temperature environments, but it is not designed for high-temperature conditions. The typical operating temperature range is -10 ℃ to 40 ℃, which ensures stable performance, accurate measurements, and proper touchscreen responsiveness. Using the tester outside this range, especially in high-temperature environments, may affect electronic components, battery life, display sensitivity, and measurement reliability.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.