The ultrasonic water tank level meter adopts an advanced ultrasonic reflection principle, with a detection range of 0~20 meters and a measurement accuracy of 0.5 level. It can automatically compensate for temperature influence and stably output a 4~20mA signal.

Real-time Sound Velocity Temperature Compensation

- Built-in high-precision temperature sensor, real-time perception of ambient temperature, automatic sound velocity temperature compensation, effectively eliminates the impact of temperature fluctuations on measurement accuracy, and ensures long-term stable and reliable data.

- The ultrasonic water tank level meter provides a variety of range options, from 0-5 meters to 0-15 meters, to meet the needs of different scenarios. Whether it is a small storage tank or a large pool, or a river, it can easily cope with it and flexibly meet your measurement range requirements.

- The electrical interface uses sturdy and durable ABS engineering plastics, which have excellent impact resistance and aging resistance, significantly improving the life of the connector and field reliability.

Visual Protection Design Scheme

- The instrument for measuring water level is equipped with a high-definition LCD display, which clearly displays the object level and liquid level at the same time. The data is clear at a glance, and the operation and observation are more convenient.

- The probe adopts a fully enclosed structure, with a high-transmittance high-quality observation window, reliable sealing, while protecting the internal precision components, it is convenient to intuitively confirm the working status on site.

- The whole machine has an IP65 high protection level, which effectively resists rain, splashing, dust, and dust intrusion, ensuring the stable operation and long service life of the equipment in harsh industrial and outdoor environments.

Applications

The use scenarios of water level meters cover multiple fields such as industry, water conservancy, environmental protection, and energy. Its applications are diversified according to the characteristics of the measuring medium, environmental requirements, and functional requirements.

Dam

Hydroelectric Power Station

Water Tank

Agricultural Irrigation

| Model | SISCO-WLM-TKCSBA |

| Range Size | 0~15m |

| Blind Area Range | 0.35~0.6m |

| Distance Measurement Accuracy | ±0.5% (Standard Conditions) |

| Resolution | 1mm |

| Withstand Voltage | 0.2Mpa |

| Output Signal | 4~20mA, RS485 |

| Supply Voltage | DC 24V |

| Ambient Temperature | -20℃~60℃ |

| Protection Level | IP65 |

| Dimensions | 30cm×20cm×15cm |

| Weight | 1kg |

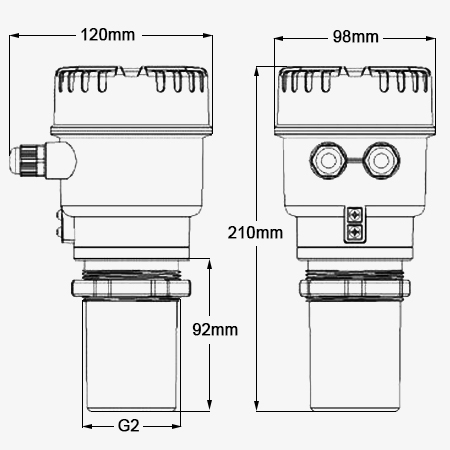

Structure diagram

Q1: How to Read a Water Level Gauge Correctly?

A1: The key to reading a water level gauge correctly is to first check the device status and environmental conditions to ensure there are no interference factors, then use the corresponding method according to its type (such as glass tube, float type, pressure type or radar/ultrasonic) to read it, usually by looking directly or viewing the display, paying attention to the units and decimal points; at the same time, make sure the device is calibrated, and pay attention to factors such as bubbles and dirt that may affect the accuracy of the reading. Finally, record the reading and do daily cleaning and maintenance to ensure the reliability of the measurement results and the life of the equipment.

Q2: How to Calibrate a Water Level Meter?

A2: The water level meter calibration needs to be completed in a static water body. First, place the probe into a known depth (such as 0cm or standard water level) to adjust the zero point, then calibrate the range by comparing the actual water depth, and set compensation parameters according to the water temperature to eliminate thermal expansion and contraction errors. After completion, record the calibration data and recheck it regularly (such as monthly) to ensure measurement accuracy.

Q3: Common Operational Errors When Using Water Level Meters

A3: Common operational errors when using water level meters include improper installation, neglect of calibration, and neglect of environmental factors. For example, when installing the probe tilted or close to the inlet/outlet, the measured value may be too large or too small, or even fluctuate unstably; failure to perform zero point calibration or neglecting that the medium density does not match the device setting value may cause inaccurate readings.

Tips: The Core Advantage of Ultrasonic Water Level Meter

The core advantage of the ultrasonic water level meter is its non-contact measurement capability. It measures water level through the principle of ultrasonic reflection, avoiding sensor pollution and corrosion caused by direct contact with water. In addition, it also has the characteristics of high accuracy (usually up to millimeter level), stable and reliable measurement, simple maintenance (no need to clean or replace sensors regularly), wide application range (applicable to various water environments such as rivers, lakes, reservoirs, etc.) and strong anti-interference ability.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.