High performance UV meter can simultaneously test the UV energy and intensity of four bands, and monitor the temperature and UV power in real time, and display the test curve. This UV meter is for UV intensity testing in equipment such as curing machines, dryers, coating machines, exposure units, and printing systems. Additionally, it includes PC software that enables easy report generation and printing.

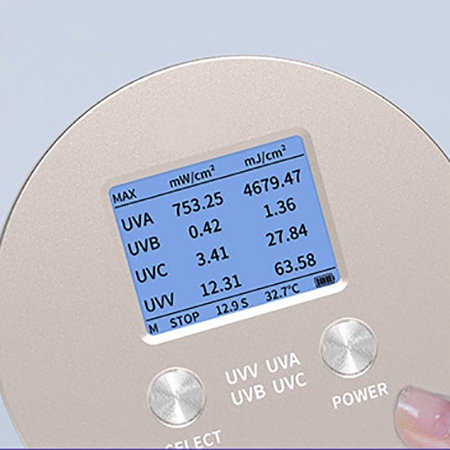

Large High-Definition LCD Display

- Clear, Easy-to-Read Readings: The oversized HD LCD screen displays UV intensity values in bold, easy-to-read digits, reducing eye strain and improving usability in both indoor and outdoor environments.

- Backlit Display for Low-Light Use: The UV energy meter equipped with a bright backlight, the screen ensures visibility in dark environments such as laboratories, sterilization rooms, or shaded industrial areas.

- Real-Time Monitoring at a Glance: The large display allows users to instantly check real-time UV readings without having to squint or interpret small characters-ideal for fast-paced or safety-critical applications.

Independently Designed Sensor

- Independent Sensing for Enhanced Accuracy: The sensor is independently designed and isolated from the main unit, minimizing electromagnetic and thermal interference for more precise UV intensity readings.

- No Cross-Interference Between Multiple Probes: In systems with multiple sensors or channels, each probe operates independently, ensuring accurate detection in multi-source UV environments without signal overlap or interference.

- Flexible Placement for Optimal Measurement: The separate sensor design allows for flexible installation in hard-to-reach or high-exposure areas, improving measurement reliability in diverse field conditions.

- Improved Stability in Continuous Operation: Isolated circuitry reduces signal noise and drift during long-term operation, making the UV meter suitable for industrial UV curing, sterilization, and continuous monitoring applications.

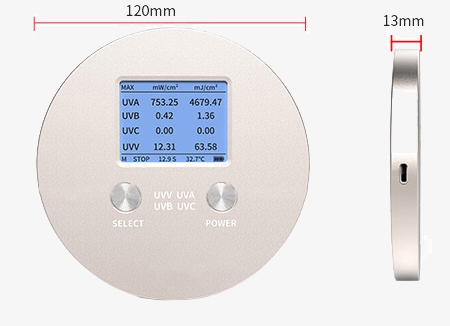

Dimension

Application

SISCO UV meter is commonly used across various industries to measure ultraviolet (UV) light intensity. Key applications include monitoring and controlling UV curing processes in manufacturing, ensuring proper UV sterilization in water treatment and healthcare, and assessing UV exposure levels in environmental testing and research. These meters are crucial for maintaining product quality, safety, and compliance with industry standards in sectors such as printing, electronics, pharmaceuticals, and environmental science.

Health and Safety

Reptile Care

Industrial

Environmental Monitoring

| Model | SISCO-UVM-138 |

| Applicable Light Source | High-pressure pump lamp, iron lamp, gallium lamp and other metal halide lamps |

| Spectral Range | UVC: 230nm~280nm, λp=254nm |

| UVB: 280nm~315nm, λp=310nm | |

| UVA: 315nm~400nm, λp=365nm | |

| UVV: 395nm~445nm, λp=420nm | |

| Power Measurement Range | 0~2000mW/cm² |

| Power Resolution | 0.01mW/cm² |

| Instrument Size | 120mm diameter |

| UV Probe Position | Back of screen |

| Energy Measurement Range | 0~999999mJ/cm² |

| Energy Measurement Accuracy | H<5mW/cm²: ±0.5mW/cm², H≥5mW/cm²: ±10%H, ±5%H typical |

| Sampling Rate | 2048 times/second |

| Power Data Storage Interval | 32 times/second |

| Temperature Data Storage Interval | 2 times/second |

| Recording Cycle | 32 minutes |

| Measurement Unit | μW/cm², mW/cm², W/m² |

| Display Temperature Curve | √ |

| Support USB Data Export | √ |

| Display Power Curve | √ |

Q1: What is a UV Meter?

A1: A UV meter is an instrument used to measure the intensity of ultraviolet (UV) light, It is commonly used in industries such as manufacturing, healthcare, and environmental monitoring to ensure proper UV exposure for applications like curing, sterilization, and UV radiation assessment.

Q2: What types of UV radiation can a UV Meter measure?

A2: A UV meter is capable of measuring various types of UV radiation, including UVA (320-400 nm), which is commonly used in tanning and curing processes; UVB (280-320 nm), which plays a key role in environmental monitoring and healthcare, particularly in skin-related studies; and UVC (100-280 nm), which is highly effective in sterilization and disinfection. Each type of UV radiation has specific applications, and a UV meter can be designed to measure one or multiple types depending on its sensors and filters.

Q3: Can a UV Meter measure UV radiation from sunlight?

A3: Yes, a UV meter can measure UV radiation from sunlight. It’s commonly used in environmental monitoring to assess the levels of UVA and UVB radiation, which are the types of UV light that reach the Earth's surface. This information is crucial for understanding UV exposure risks, studying environmental impacts, and ensuring public safety.

Tips: Can UV intensity meters be used for personal safety?

Yes, UV intensity meters can be used for personal safety. They are particularly useful in environments where UV light exposure is common, such as tanning salons, laboratories, or workplaces with UV sterilization or curing equipment. By measuring the intensity of UV radiation, these meters help ensure that individuals are not exposed to unsafe levels of UV light, which can cause skin damage, eye injuries, or other health issues.

For example:

- In tanning salons, UV intensity meters ensure that the UV lamps emit safe levels of UV radiation.

- In UV sterilization environments, they help monitor UV exposure to prevent overexposure, which could be harmful.

- In outdoor settings, they can measure UV index levels, helping people avoid excessive sun exposure.

Using a UV intensity meter helps maintain safety by providing real-time data on UV levels, allowing for adjustments to protect individuals from harmful UV radiation.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.