A gloss meter is an instrument used to measure the degree of surface gloss on objects such as plastics, inks, paints, coatings, marble, granite, and coated surfaces. It finds extensive application in industries such as chemical raw materials, coatings manufacturing, automotive, electronics, electrical appliances, and other fields requiring specialized measuring instruments. High-precision gloss meters are categorized into high gloss, medium gloss, and low gloss types based on the measurement angle. In this article, Sisco will introduce the working principle, usage, application range, and precautions for testing gloss meters to help you gain a better understanding of this instrument.

Working Principle of Gloss Meter

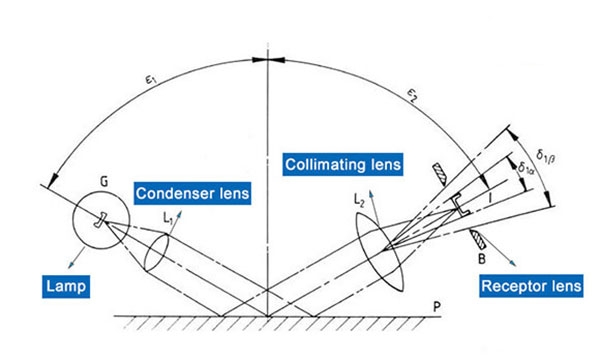

Gloss is a physical quantity that evaluates the ability of a material surface to reflect light under specified geometric conditions, possessing directional reflective properties. The gloss we commonly refer to is "specular gloss," hence gloss meters are sometimes called "specular gloss meters." To measure the gloss of an object's surface, components such as a light source emission device, a reflected light receiver, and a data analyzer are necessary. The working principle of a gloss meter is as follows:

Light source G emits a beam of light that passes through lens L1 to reach the measured surface P. The surface P reflects the light to lens L2, which converges the light to the photodiode located at position B in the light path. After photodetection, the photodiode converts the light signal into an electrical signal, which is then sent to the processing circuit for analysis, and the instrument displays the measurement result.

Under specified conditions of light source and receiver angles, the ratio of radiant light energy (light flux) in the specular reflection direction of the sample to the radiant light energy (light flux) in the specular reflection direction of a standard black glass sample is the gloss value of that sample. Polished black glass with a refractive index of 1.567, at a geometric angle of 60 degrees, is set as the standard with a gloss value of 100 (gloss units).

Operation Methods for Gloss Meter

- Power On/Off:

Press and hold the "Power/Measurement Button" for 3 seconds to turn on the instrument. The indicator light will illuminate, displaying the logo interface. After waiting for a few seconds, the instrument will automatically enter the measurement interface. To power off, press and hold the "Power/Measurement Button" for 3 seconds after turning on the device. - Calibration:

Automatic Calibration Instructions The instrument features an automatic calibration function upon startup. However, for greater convenience and flexibility in using the instrument, an option to choose whether the instrument automatically calibrates on startup is provided. If the last shutdown was manual, the instrument will automatically calibrate on the next startup. If the last shutdown occurred after 5 minutes of screen-off automatic shutdown, the instrument will not automatically calibrate on the next startup.

Calibration is essential when there are significant changes in the operating environment (such as temperature, altitude, humidity). To ensure precise calibration, use the standard plates provided by the manufacturer. Dust on the standard plate can affect calibration accuracy, so before calibration, wipe the working surface of the standard plate with a cleaning cloth to ensure cleanliness.

The standard plate is a precision optical component, so it should be protected from exposure to direct sunlight. Due to environmental factors, the photometric data of the standard plate may change over time. Therefore, it is recommended to periodically send the standard plate back to the original manufacturer or a qualified metrology institute for calibration testing (recommended annually). - Measurement:

The gloss meter automatically calibrates upon startup, providing a simple and convenient operating mode. The measurement mode is the basic mode, which is the sample measurement mode. It directly displays gloss measurement values and belongs to a single measurement mode. Simultaneously, it can display three sets of measurement data.

Tips for Gloss Meter Testing

Tips for Gloss Meter Testing

- The calibration plate of the gloss meter must be kept clean, free of dust and stains. An unclean calibration plate can lead to inaccurate test data. Place the calibration plate directly on the gloss meter base for correct operation.

- The gloss meter must have a self-check and self-calibration function upon startup, automatically diagnosing and promptly detecting system errors, improper operation, or contamination of the standard plate that could lead to the instrument failing to pass self-calibration.

- After use, store the gloss meter in an environment free from heat sources and corrosive substances, ensuring a dry storage location.

Application Range of Gloss Meter

- Surface gloss measurement of materials such as inks, paints, and coatings.

- Surface gloss measurement of building decorative materials, including marble, granite, glazed polished tiles, and ceramic tiles.

- Measurement of surface gloss of plastics, coated paper, and other materials.

- Measurement of surface gloss of other non-metallic materials.

- Measurement of the surface smoothness of coatings.

In summary, gloss meters play a vital role in maintaining and ensuring the quality of surfaces by quantifying their reflective properties. They are valuable tools in industries where appearance and finish are critical quality attributes.