An Inside Micrometer, also known as an internal micrometer or bore micrometer, is a precision measurement tool used to measure the internal diameter or bore of a hole, cylinder, or other internal features. It is particularly useful in applications where accurate measurements of internal dimensions are required.

Key Components

Here are the key components and features of a typical inside micrometer:

- Measuring Jaws: An inside micrometer consists of two sets of measuring jaws or anvils. These jaws are designed to be inserted into the internal feature being measured, such as a bore, cylinder, or groove.

- Main Scale and Vernier Scale: Inside micrometers have a main scale and a vernier scale, which is a secondary scale that allows for precise readings. The main scale provides a rough measurement, while the vernier scale is used for fine adjustments and reading. The vernier scale is marked with graduations in either thousandths of an inch or tenths of a millimeter, depending on the micrometer's measurement system.

- Thimble: The thimble is the rotating component of the micrometer that contains the vernier scale. It can be rotated to advance or retract the measuring jaws, allowing them to contact the internal surface and take a measurement.

- Ratchet Stop: Many inside micrometers are equipped with a ratchet stop mechanism. This ensures consistent and controlled pressure on the measuring jaws to prevent over-tightening and ensure accurate measurements.

Working Principle

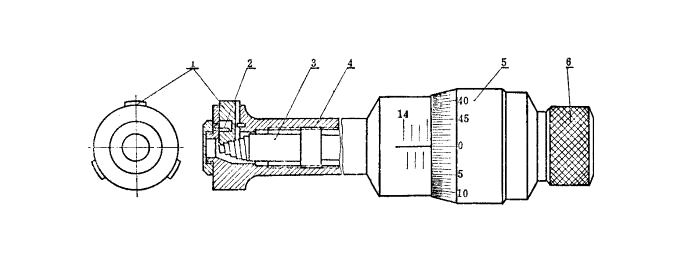

The picture below shows a 3-point inside micrometer with a measuring range of 11~14mm. When the force measuring device 6 is rotated clockwise, it will drive the micrometer screw 3 to rotate and make it move along the helical direction of the threaded sleeve 4, so the square conical thread at the end of the micrometer screw will push the three measuring jaws 1 For radial movement. The elastic force of the torsion spring 2 makes the measuring claw fit tightly on the square conical thread, and expands and contracts with the advance and retreat of the micrometer screw. The radial pitch of the square conical thread of the 3-point internal diameter micrometer is 0.25mm. When the force-measuring device rotates clockwise for one revolution, the measuring jaw 1 will move outward (radially) by 0.25 mm, and the diameter of the circle formed by the three measuring jaws will increase by 0.5 mm. When the microtube rotates once, the measurement diameter increases by 0.5mm and 100 equal divisions are engraved on the circumference of the microtube, so its reading value is 0.5mm÷100=0.005mm. This is how an inside micrometer works.

Inside Micrometers Advantages

- High Precision: Inside micrometers provide exceptionally precise measurements, typically down to thousandths of an inch or tenths of a millimeter. This level of precision is crucial for applications where tight tolerances must be met.

- Repeatability: They offer excellent repeatability, ensuring that measurements taken at different times or by different users are consistent and reliable.

- Versatility: Inside micrometers are versatile tools that can measure a wide range of internal features, including holes, bores, and cylindrical objects. They come in various sizes and designs to accommodate different measurement needs.

- Ease of Use: While they require some skill to use effectively, inside micrometers are relatively user-friendly and can provide accurate measurements with practice and proper technique.

- Non-Destructive: Inside micrometers are non-destructive measurement tools. They allow you to assess the internal dimensions of components without causing any damage or alteration to the part being measured.

Inside micrometers are available in various sizes and designs to accommodate a wide range of bore diameters and depths. They are commonly used in industries like machining, engineering, and quality control for applications such as checking the internal dimensions of machined parts, verifying the size of holes, and ensuring that tolerances are met with a high degree of accuracy. The precision and repeatability of inside micrometers make them essential tools for quality assurance and precise manufacturing processes. sisco provides high-quality inside micrometer, welcome to purchase.