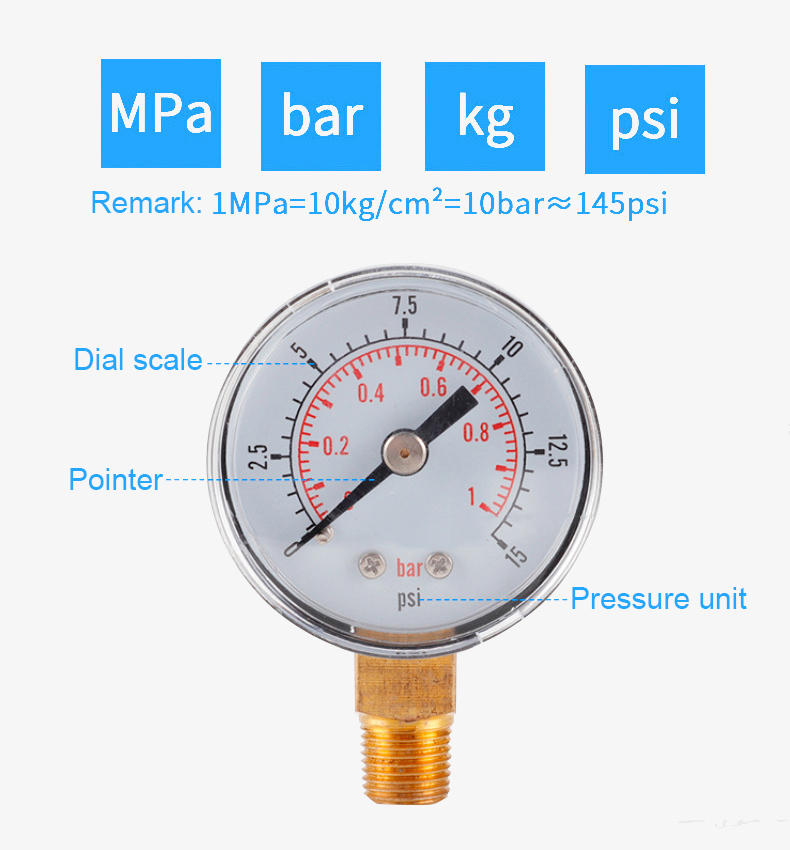

Hot selling pressure gauge is available with a 0~11 bar measuring range, 40mm dial diameter, a dual-scale display, stainless steel materials and 1/8" BSPT thread. 0 to 160 psi pressure gauge is designed for measuring water pressure, hydraulic pressure, oil pressure and air pressure, suitable for metallurgy, electric power, petroleum, chemical industry, light industry, and machinery.

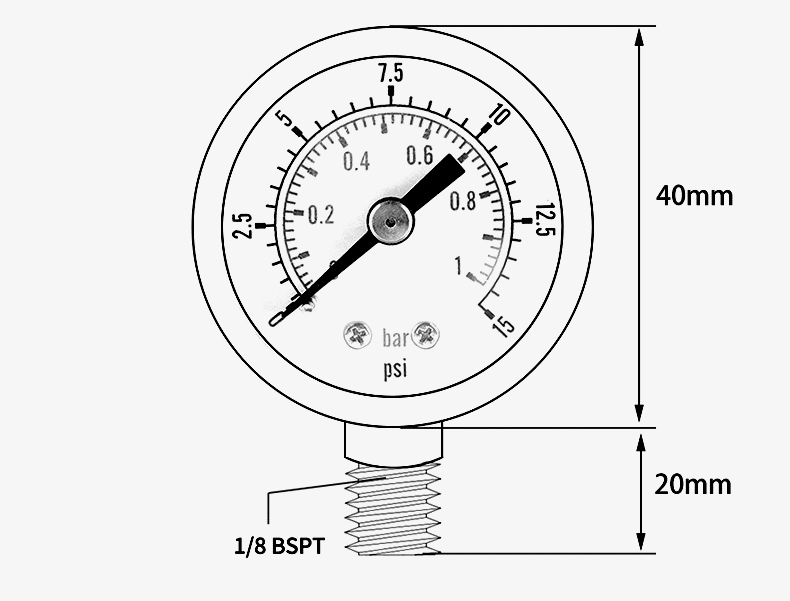

Pressure gauge, φ40mm dial diameter, 1/8 installation diameter, BSPT thread, 0~160 psi & 0~11 bar measuring range.

- 0 to 160 psi pressure gauge can be used as a water pressure gauge, air pressure gauge, hydraulic pressure gauge and oil pressure gauge.

- Circular dial is enclosed in a stainless steel case for corrosion resistance. Diaphragm pressure gauge offers clear readings and is weather-resistant.

- Brass and stainless steel wetted parts for measuring non-corrosive liquid and gas pressure. Such as water, oil, fuel, coolant, air, co2, nitrogen, and argon pressure test.

- sisco pressure gauge with dual scale (0~160 psi/0~11 bar). Display accuracy of 2.5% over the entire range of the gauge.

- It also has a lower-mount male connection with a 1/8" BSPT thread.

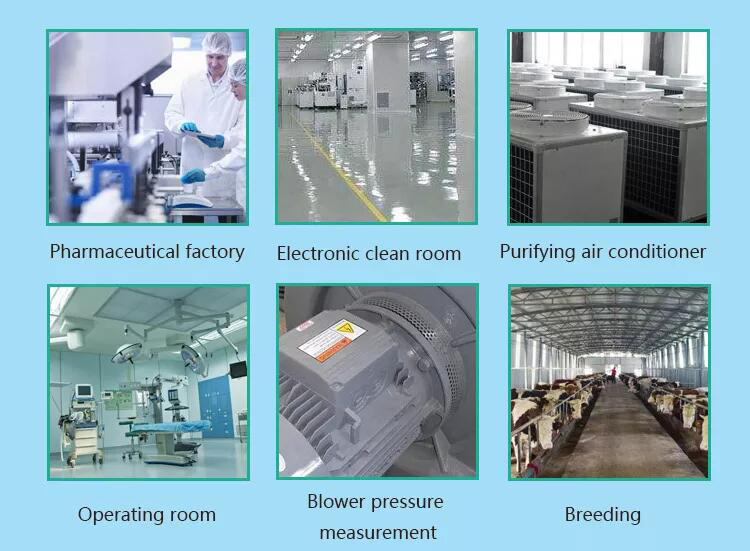

Applications

Pressure gauge is the most commonly used measuring instrument for displaying and controlling pressure. sisco diaphragm pressure gauges are widely used in the chemical industry, petroleum, metallurgy, mining, and electric power production, especially in vehicle maintenance shops, heat pipe networks, water and gas supply systems, etc.

- Model: SISCO-TS-Y408-160psi

- Dial Diameter: φ40mm

- Installation Method: Radial

- Range: 0~160 psi, 0~11 bar

- Installation Diameter: 1/8

- Thread Specification: BSPT

- Size: 6x4x2.5cm

- Material: Stainless Steel

- Package Size: 8.5x6.5x4.5cm

- Product Weight: 44g

- Package Weight: 60g

Dimension (Unit: mm)

Q1: What is a pressure gauge?

A1: A pressure gauge refers to an instrument that uses elastic elements as sensitive elements to measure and indicate pressure higher than the environment. It is used in almost all industrial processes and scientific research fields, mainly in heat pipe networks, oil and gas transmission, water and gas supply systems, and vehicle maintenance. Maintenance shop, etc. Especially in the process of industrial process control and technical measurement, mechanical pressure gauges are becoming more and more popular due to the high mechanical strength and convenient production of the elastic sensitive components of mechanical pressure gauges.

Q2: How does a pressure gauge work?

A2: The pressure gauge transmits the pressure deformation to the pointer through the elastic deformation of the sensitive components (Bourdon tube, diaphragm box, bellows) in the watch, and then the conversion mechanism of the watch movement, causing the pointer to rotate to display the pressure. This is the working principle of a pressure gauge.

Q3: What is a pressure gauge used for?

A3: sisco pressure gauges are both air pressure gauges and water pressure gauges and are mainly used for pressure detection in metallurgy, electric power, petroleum, chemical industry, light industry, machinery, etc. The pressure gauge relies on measures such as internal filling of damping oil and matching buffer devices, and has good shock resistance. It is suitable for occasions where the pressure of the measured medium has strong pulse changes or pressure shocks, and often suddenly unloads in the production process, as well as environmental vibrations. The pressure gauge can measure the average value of the pulsating pressure of gas and liquid, so as to overcome the damage caused by the strong pulse of the medium and the vibration of the environment to ensure the accuracy of the reading.

Tips:

3 problems in the use of pressure gauges

- The fan gear of the pressure gauge will wear out after working for a period of time.

- The pressure measuring system of the pressure gauge is impacted by the instantaneous overpressure of the measured medium so that the pointer cannot return to the zero position or rushes under the limit nail.

- The pointer of the pressure gauge will not return to the zero position after the system is depressurized.

3 Ways to solve pressure gauge problems

- Increase the width of the contact surface of the sector gear to achieve the purpose of anti-wear and increase the service life of the pressure gauge.

- Install a limit block on the movement of the pressure gauge. When the pressure measurement system is subjected to an instant impact, the cylindrical gear and sector gear of the movement is not easy to trip, so as to solve problem 2.

- The impact pressure measurement system closes the valve below the pressure gauge.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.