An analog Barcol hardness tester is a portable instrument used to measure the hardness of materials such as aluminum, fiberglass, and hard plastics. Unlike digital model, the analog Barcol tester uses a simple mechanical system with a pointer and scale, no batteries required. This kind of hardness tester provides immediate readings and is widely used in quality control, manufacturing, and maintenance processes.

Barcol Hardness Tester Equipped Pointer Display

- The most significant advantage of the pointer dial is that it provides instant, direct readings without the need for digital conversion. This reduces the chance of electronic interference.

- Unlike digital tester, which rely on batteries or circuitry, the pointer dial version is entirely mechanical, providing dependable performance and minimal maintenance.

- A Barcol hardness tester with a pointer dial is user-friendly and intuitive. Operators can easily observe the needle movement and ensure proper contact with the material surface.

Easy to Operate

- Perform the pressing operation by firmly pressing the Barcol hardness tester perpendicular to the sample surface.

- A portable Barcol tester is designed to be simple to operate. Its compact structure, lightweight body, and manual pressing mechanism allow even non-specialists to carry out hardness tests with minimal training. The straightforward operation enhances productivity and reduces the potential for user error.

Applications

SISCO's Barcol hardness tester is mainly used to test the hardness of aluminum and aluminum alloys. It can also test the hardness of other soft metals and glass steel products. In composite materials manufacturing, especially in aerospace and automotive sectors, the tester is used to assess curing quality and uniformity of fiber-reinforced plastics.

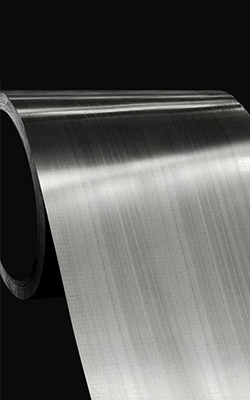

Aluminum Sheet

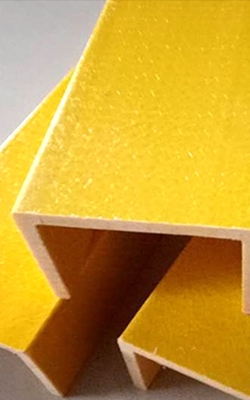

Fiberglass

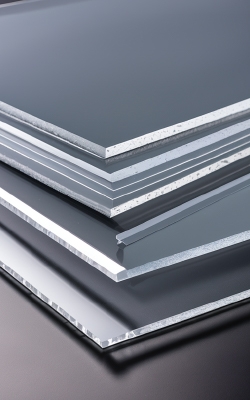

Hard Plastic

Aluminum Alloy

| Model | SISCO-HT-934-1 |

| Indenter | 26° truncated cone, end face diameter 0.157mm |

| Measurement Range | 0~100HBa (Effective measurement range equivalent to 25~135HBW) |

| Resolution | 0.5HBa |

| Indication Error | 42~52 HBa ±2.0 HBa 84~88 HBa ±1.0 HBa |

| Repeatability Error | 42-52 HBa ±2.5 HBa 84~88 HBa ±1.5 HBa |

| Dimension | 140*35*87mm |

| Weight | 545g (net weight); 1288g (cross weight) |

Dimension:

Q1: What is a Barcol hardness tester?

A1: A Barcol hardness tester is a handheld device used to measure the hardness of soft metals, plastics, composites, and other materials. It operates using a spring-loaded indenter that presses into the material's surface, and the depth of penetration determines the hardness value. The device provides a quick, and convenient method for assessing material strength, especially in production and quality control environments.

Q2: What maintenance is required for a Barcol hardness tester?

A2: First, the Barcol tester should be kept clean and free of dust or debris. Store the tester in a protective case when not in use to prevent physical damage. Avoid exposing it to extreme temperatures, humidity, or corrosive environments. Finally, handle the tester carefully, avoiding dropping or applying excessive force.

Q3: What are the types of Barcol hardness tester?

A3: Barcol hardness testers are primarily used to measure the hardness of soft metals and plastics. There are two main types: analog (dial/pointer type) and digital.

- Analog/Pointer Barcol Hardness Tester: Uses a mechanical dial and pointer to display hardness values. It's simple, reliable, and doesn't require batteries, but reading precision depends on user observation.

- Digital Barcol Hardness Tester: Equipped with a digital display for direct reading of hardness values. It offers higher accuracy, easy data recording.

Tips: What are the advantages of an analog pointer over a digital tester?

An analog pointer Barcol hardness tester offers several advantages over digital models. Firstly, it provides instant, continuous readings, allowing the user to observe the needle's behavior in real time, which can be helpful for detecting surface inconsistencies. It is generally more durable, making it reliable in harsh environments. Analog devices are simpler to operate, with no need for batteries or calibration menus, and they can offer better tactile feedback during testing.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.