High performance automotive brake fluid tester's gooseneck probe provides flexibility in detection, making the detection process more elastic and efficient. This digital brake fluid tester with high sensitive probe, high resolution screen and audible alarm, instant display result, large display with backlight, easy and clear reading in sun or night.

High-Sensitivity Quick-Response Probe Ensures Accurate and Stable Detection

- High-Sensitivity Probe: Equipped with advanced sensors, the probe quickly detects moisture levels in brake fluid, providing fast and reliable results.

- Accurate Measurements: The sensitive probe ensures precise readings even when water content is minimal, reducing false alarms or errors.

Quick Response: Provides almost instantaneous feedback, allowing multiple vehicles or samples to be tested efficiently. - Durable Construction: The probe is designed to withstand repeated use and exposure to brake fluid without degradation, ensuring long-lasting performance.

- User-Friendly: Easy to operate with a simple dip-and-read method, making it convenient for both professional mechanics and car owners.

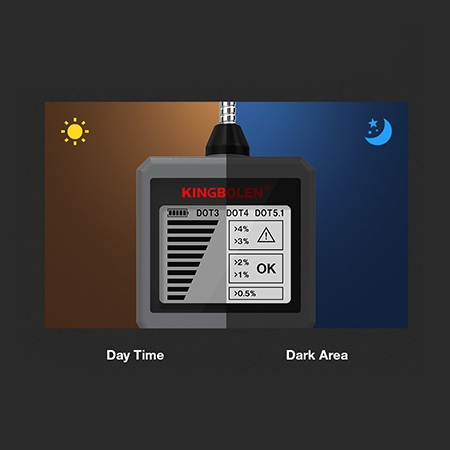

High-Resolution Backlit Screen for Clear Readings Day or Night

- High-Resolution Display: Shows clear and precise test results, making it easy to read at a glance.

- Visible in All Conditions: Backlit screen ensures readability in low-light conditions, such as at night, and remains clear under bright sunlight.

- Quick Result Feedback: The screen instantly displays the test outcome, reducing waiting time and improving efficiency.

- User-Friendly Interface: Clear digital readout or LED indicators simplify operation, even for first-time users.

- Durable and Reliable: The high-quality display is designed to withstand frequent use and resist scratches or smudges.

Dimension

Applications

SISCO brake fluid tester is widely used in automotive workshops, inspection stations, fleet maintenance, and by car owners for routine vehicle care. It quickly detects moisture content or boiling point changes in brake fluid, helping ensure reliable braking performance and compliance with DOT standards (DOT 3, DOT 4, DOT 5.1). This makes it an essential tool for mechanics, inspectors, and drivers to maintain safety and prevent brake failure.

Inspection Stations

Fleet Maintenance

Automotive Workshops

Routine Vehicle Care

| Model | SISCO-BFT-BF200 |

| Material | ABS |

| Maximum Supply Voltage | 3V |

| Test Range | DOT3, DIT4, DOT5.1 |

| Response Time | 5s |

| Output Type | Digital |

| Temperature | -10~50℃ |

| Dimensions | 6.4*2.17*0.94 inch |

| Weight | 150g |

Q1: What is a brake fluid tester?

A1: A brake fluid tester is a tool used to check the condition of brake fluid in a vehicle. It measures factors like water content or boiling point, since moisture in brake fluid lowers its effectiveness and can lead to brake failure. By providing a quick pass/fail or percentage reading, it helps determine whether the brake fluid is safe to use or needs to be replaced.

Q2: What types of brake fluid can a brake fluid tester test?

A2: Most brake fluid testers are designed to test glycol-based fluids, including DOT 3, DOT 4, and DOT 5.1. These are the most common types used in passenger cars and light trucks. They are not suitable for DOT 5 silicone-based brake fluid, which requires different testing methods.

Q3: How does a brake fluid tester work?

A3: A common brake fluid tester works by submerging its electrodes into the brake fluid, then measuring the electrical conductivity of the fluid. Because brake fluid naturally absorbs water over time, this water increases its conductivity. The tester uses a traffic light system of LEDs to indicate the percentage of water content and the overall condition of the fluid, with green meaning no water and red indicating a high level of moisture that requires a brake fluid flush.

Tips: How often should brake fluid be tested?

Brake fluid should ideally be tested at least once a year or during every routine vehicle service. Because brake fluid is hygroscopic, it naturally absorbs moisture from the air over time. Even small amounts of water in the fluid can significantly lower its boiling point, which increases the risk of vapor lock, brake fade, or total brake failure under heavy braking or high-temperature conditions.

For vehicles that experience extreme conditions—such as high ambient temperatures, frequent stop-and-go driving, towing, racing, or heavy-load operation—it is recommended to test brake fluid more frequently, sometimes every 6 months, to ensure optimal braking performance and overall safety.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.