Phase detector is a noncontact phase tester, designed for phase judgment and phase sequence testing of handcart-type metalclad withdraw switchgear in the 10kV-35kV power distribution system. It features a 0°~360° phase range, 20m detecting distance and 45.0Hz~65.0Hz frequency range. 3.5-inch true-color LCD screen can display phase, frequency, phase sequence and test results on the same screen, phase tester is widely used in the power industry, electronic manufacturing, industrial control and so on.

Digital phase detector, with 10V~35kV voltage range, 0°~360° phase range, 45.0Hz~65.0Hz frequency range and 20m phase distance.

- SISCO electrical phase detector adopts non-contact phase detection technology to receive phase detecting data outside the cabinet to avoid the risk of direct contact between operators and high voltage in the cupboard and ensure the safety of personnel and equipment.

- A, B, C three phases complete the phase detection simultaneously, making detection accurate and operation convenient.

- Digital phase detector with a 3.5-inch LCD color screen can display the phase, frequency, phase sequence, and phase-detecting results on the same screen, audible alarm function is available. The dynamic vector diagram indication is clear and obvious.

- The motor and phase rotation tester has a data storage function; the phase detector can store 200 groups of data.USB interface with data upload function, stored data can be uploaded to the computer, saved, and printed.

Details

Applications

SISCO digital phase tester can perform phase tests and phase sequence tests of power lines and substations, with phase verification, phase sequence measurement, and electrical inspection functions. Strong anti-interference performance and is suitable for various electromagnetic field interference occasions. Phase detector is widely used in the power industry, electronic manufacturing, industrial control and other industries.

| Model | SISCO-PT-1540 |

| Power Supply | Host: 3.7V, 2600mAh rechargeable lithium battery; Detector: 3.7V, 600mAh rechargeable lithium battery |

| Phase Detecting Voltage | AC 10kV~35kV |

| Phase Detecting Distance | 20m |

| Voice Prompt | "X signal normal, Y signal normal, same phase, out phase". |

| Phase Qualitative | Same phase: -20°~20°; Out of phase:100°~140° and 220°~260° |

| Phase Range | 0°~360°; Accuracy: ≤±8"; Resolution∶1° |

| Frequency Range | 45.0Hz~65.0Hz; Accuracy: ±2 Hz; Resolution∶0.1Hz |

| Transmitting Frequency | 433MHz, 315MHz |

| Phase Indication | Vector diagram and digital display at the same time |

| Data Storage | 200 groups (Power down will not lose data) |

| Automatic Shutdown | 15 minutes after boot up, the meter shuts down automatically without any operation |

| Battery Voltage | The host battery shows the power level of 4 cells. When there is only 1 cell or 0 cell, please charge; when the indicating light of the detector flashes quickly, which means that the battery voltage is low, please charge. |

| Rated Current | Detector: 30mA max; Host: 150mA max |

| LCD Size | 3.5 inch color screen; Display area: 71mmx53mm |

| Weight | Host: 950g (including battery) |

| Instrument Dimension | Host 195mm"100mm*45mm; Detector: 120mmx54mmx30mm |

| Working Temperature And Humidity | -10℃~40℃; below 80%rh |

| Store Temperature and Humidity | -10℃~60℃; below 70%rh |

| Protection Level | IP63 |

| Suitable Safety Standard | It meets the standard of GB13398-92, GB311.1-311.6-8, 3DL408-91, and the national power industry standard requested general |

| technical conditions DLT 971-2017 for 1kV~35KV portable nuclear phase devices for live working. | |

| Insulation Test | Host, detector: AC3700V/rms (between the exposure metal and plastic shell) |

| Accessories | Host: 1PCS, Detector 2PCS, USB Data Cable: 1PCS, Cloth Bag: 1PCS, Charger: 1PCS; Aligator Clip: 2 PCS |

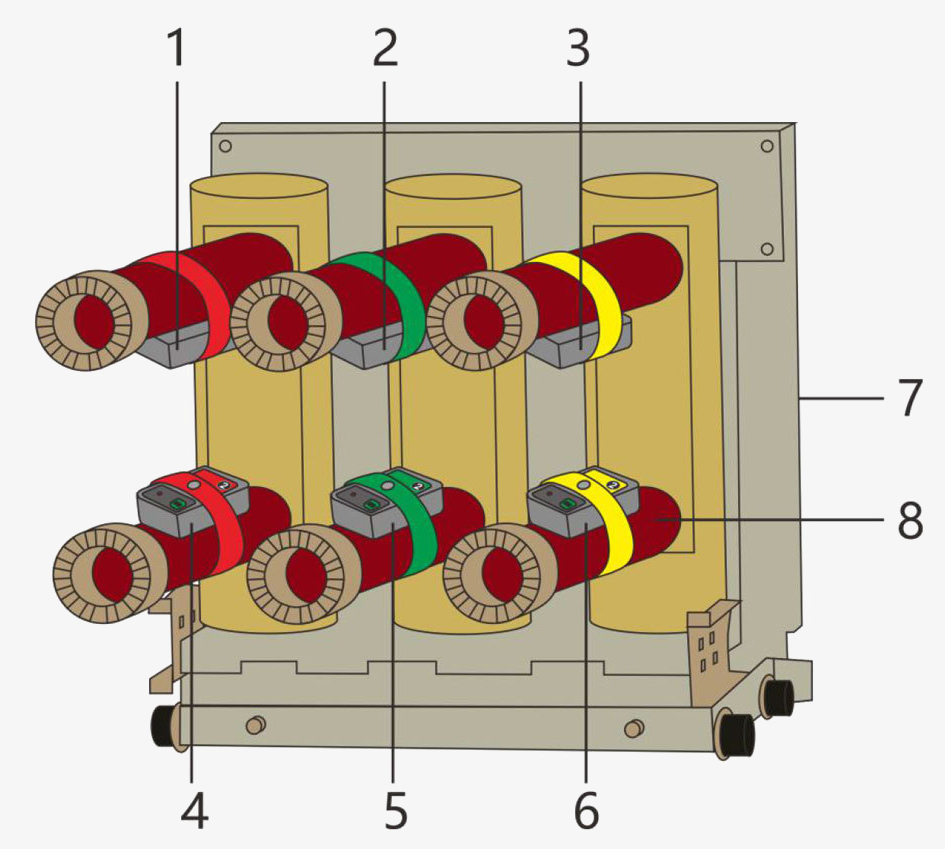

Diagram

- Detector C1 (red)

- Detector B1 (green)

- Detector A1 (yellow)

- Detector C2 (red)

- Detector B2 (green)

- Detector A2 (yellow)

- Handcart switch cabinet

- Tentacle arm

Package List

Q1: How does a phase frequency detector work?

A1: When the phase frequency detector is working, the digital signal is sent to the receiving end through the wireless sending module, thereby reducing the interference and error, and greatly improving the working performance of the phase tester. When the phase detector is in use, first hang the transmitter on the conductor of the power grid under test, and then touch the receiving device to another grid conductor to be tested.

Q2: Functions of phase detectors

A2: SISCO phase detectors can perform phase sequence detection (positive phase, anti-phase, default phase), live line inspection, simple electrical inspection, fire line identification, default phase judgment, broken line location search, DC line breakpoint detection, and line maintenance.

Q3: Why do you need a digital phase tester?

A3: If AC power supplies with different phases or phase sequences are paralleled or closed, a large current will be generated, which will cause damage to the generator or electrical equipment, so a digital phase detector is required for measurement.

Phase verification refers to the use of a tester or other means to check whether the phases and phase sequences of two power sources or loops are the same in the electrical operation of the power system, which means the measurement of the phase difference in the actual operation. Newly built, rebuilt and expanded substations and transmission lines, as well as after the line is overhauled and before power is sent to users, must conduct three-phase circuit phase verification tests. Therefore, a phase tester is required.

Tips: Advantages of a non-contact phase rotation tester

- The non-contact tester has robust security and reliability. The non-contact measurement does not touch the liquid and gas in the tank, which is very safe. Even if the tester is damaged or repaired, it will not cause leakage, poisoning, or explosion.

- Simple structure, small size, light weight, good portability, and easy installation and maintenance.

- High durability, no mechanical moving parts in the sensor and instrument, good sealing, isolated from the outside world, and will not wear or corrode.

- The pressure, temperature, density, dielectric constant, viscosity and corrosiveness of the measured medium have little influence on it.

- The non-contact tester can be used for remote measurement, and can also be used for the size of displacement, speed, phase and other parameters of rotating equipment.

This 10kV~35kV phase detector is a non-contact tester. It receives phase test data outside the central cabinet and can complete phase judgment and phase sequence tests for A, B, and C three-phase lines at the same time, avoiding the need for operators to communicate with the inside of the cabinet. The risk of direct contact with high-voltage electricity ensures the safety of operators and equipment.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.