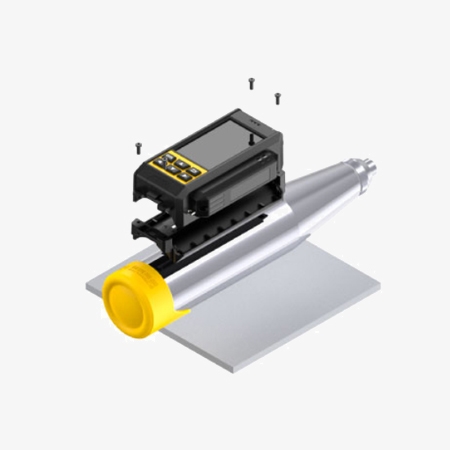

The digital rebound hammer is a high-performance tool designed for non-destructive testing (NDT) of concrete compressive strength. With its cutting-edge laser detection technology and digital interface, this concrete test rebound hammer test equipment delivers accurate, repeatable results — ideal for quality control, structural inspections, and construction site evaluations.

User-Friendly Operation with Touch & Button Inputs

- The concrete strength test hammer features a user-friendly interface with multiple input methods — touch and physical buttons, ensuring easy operation and intuitive navigation.

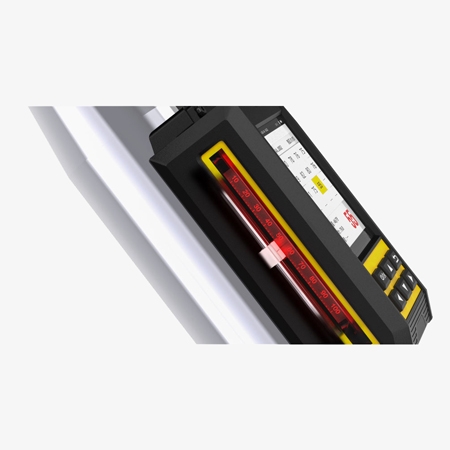

- The digital concrete test hammer equipped with a non-contact, frictionless laser detection module that offers higher accuracy and extended service life compared to traditional mechanical sensors.

- Integrated Bluetooth chip supports optional Bluetooth printer for on-site printing of original test records and measurement results.

- The digital Schmidt hammer comes with dedicated PC analysis software that simplifies data processing, result evaluation, and test report generation.

Optional GPS and Cloud Upload Support

- Compatible with optional GPS module, includes a pre-configured data transmission account for instant cloud upload upon startup.

- Delivers reliable rebound values for non-destructive testing (NDT) of concrete compressive strength in accordance with industry standards.

- Compact and robust construction makes it suitable for both field and laboratory use, ideal for engineers and construction inspectors.

- Displays test results in real-time and supports data storage, retrieval, and export for streamlined documentation and traceability.

Applications

Rebound hammers find extensive applications in the construction and engineering industries for evaluating the quality, strength, and integrity of concrete structures. Some of the key applications include building inspection, project acceptance, cement plant inspection and highway bridge inspection.

Project Acceptance

Cement Plant Inspection

Highway Bridge Inspection

Building Inspection

| Model | SISCO-RH-HT225K |

| Input Method | Touch, key |

| Display Mode | 2.8-inch touch LCD screen (400×240 pixels) |

| System Capacity | 1000 components, maximum number of measurement areas per component is 100 |

| Power Supply | Rechargeable, built-in 3200mAh high-capacity imported lithium battery |

| Automatic Shutdown | Can be set to a maximum of 120 minutes |

| Sensor Life | More than 200,000 times |

| Measurement Range | 10-60 MPa |

| Nominal Kinetic Energy | 2.207J |

| Strength of Spring | 785.0±30N/m |

| Stroke of Impact Hammer | 75mm |

| Friction of Pointer | 0.65±0.15N |

| Stretch Length of Spring | 75±0.3mm |

| Working Length of Spring | 61.5±0.3mm |

| Spherical Radius of the End of the Impact Rod | 25±1.0mm |

| Indication Consistency Error | ≤±0.5 |

| Anvil Calibration Rebound Value | 80±2 |

| Strength Test Compressive Strength Range | 10~60 MPa |

Q1: What is a digital rebound hammer and how does it work?

A1: A digital rebound hammer is a non-destructive testing (NDT) device used to assess the compressive strength of concrete. It measures the rebound value of a spring-loaded mass impacting the concrete surface. The digital version features a touchscreen interface, laser sensor for higher accuracy, and real-time display of test results.

Q2: How accurate is the digital rebound hammer compared to analog models?

A2: Thanks to its advanced laser detection module, the digital rebound hammer offers greater measurement precision by eliminating friction and mechanical contact. This leads to more

consistent and reliable concrete strength readings, especially over extended periods of use.

Q3: Can the rebound hammer connect to a printer or PC?

A3: Yes, the device has a built-in Bluetooth module that supports optional Bluetooth printers for on-site printing of test results. It also includes dedicated PC software for data analysis,

report generation, and result archiving.

Tips: Is the digital rebound hammer suitable for all types of concrete testing?

Yes, the digital rebound hammer is widely used for non-destructive concrete strength tests on a variety of structures, including bridges, tunnels, buildings, and precast elements. It complies with international concrete testing standards and is ideal for on-site inspections as well as quality control in construction projects.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.