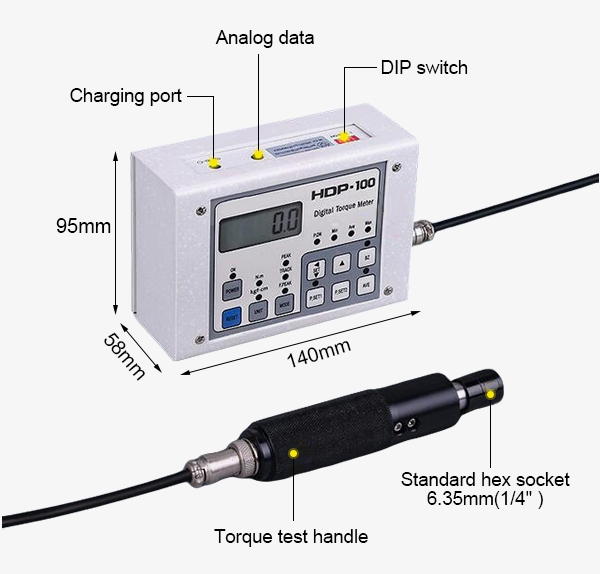

The portable torque meter with torque test handle, a high-definition LCD that displays torque values in real time and is switchable. Torque measuring tools work at a 110-220V AC power supply, making it convenient for testing and calibrating the torque accuracy of screw-tightening tools.

High-precision torque sensor, torque meter handle design

- The torque meter handle is used to connect an electric or pneumatic screwdriver and transmit the torque output of the screwdriver head to the torque tester, which uses a sensor to detect the real-time torque value.

- The torque test handle ensures that the screwdriver is firmly connected to the portable torque meter interface, preventing it from slipping or shifting.

- The torque meter adapter features a built-in high-precision torque meter sensor. The screw torque meter specifications extend its compatibility with a wide range of torque accessories, including electric screwdrivers, pneumatic screwdrivers, torque meter wrenches, and electric motors.

High-resolution LCD screen, button-type control, and buzz alarm

- The torque tester for motor comes with a high-resolution LCD screen that displays current torque measurement changes in real time, ensuring accurate data readings.

- The digital torque tester's LCD supports one-touch switching of torque units (e.g., N·m, kgf·cm, lbf·in), features a high-precision display, and peak/real-time modes.

- With a buzz alarm, the shaft torque meter's control button includes functions for mode switching, analog data, and dip switch.

Digital Torque Meter Structure

Application

A digital torque tester is an electronic device used for torque measurement and torque meter calibration. It's used to detect the torque output of tools like electric screwdrivers and torque meter wrenches, accurately measure the torque used to tighten or open bottle caps, and measure the tightening torque of bolts and nuts. Electronic torque meters are used for component assembly testing in the electronics manufacturing industry, home appliance production, automotive, and machinery.

Torque Wrenches

Electrical Appliances

Automotives

Screwdrivers

| Model | SISCO-TM-HDP-50 | SISCO-TM-HDP-100 | |

| Range | N.m | 0.1-5.0 | 0.15-10.0 |

| Lbf.in | 1.0-45.0 | 1.5-90.0 | |

| kgf.cm | 1.0-50.0 | 1.5-100.0 | |

| Torque Measurement Mode | Measurement mode: PEAK [peak mode] / TRACK [variable value mode] / F.PEAK [first peak mode] | ||

| 3 Unit Conversions | N.m/ Lbf.in/ kgf.cm | ||

| Mean Value Mode (AVE) | Torque average test | ||

| Able to set maximum torque and preset torque level value to sound a buzzer warning | |||

Q1: What is a digital torque meter?

A1: A digital torque meter is an electronic measuring instrument used to accurately test and display the torque applied to a rotating system, such as a motor, gearbox, fastener, or tool. Unlike analog torque gauges, it uses digital sensors (often strain gauge or piezoelectric) to convert torque into an electrical signal, which is then processed and shown on a digital screen.

Q2: How does a digital torque meter work?

A2: An electric torque meter uses a torque meter sensor (usually a strain gauge or piezoelectric element) that detects the twisting force (torque) applied. The torque meter sensor converts this mechanical force into an electrical signal, which is then processed by internal electronics and shown as a torque value on the digital display.

Q3: How to use a digital torque meter?

A3: Fix the handheld torque meter – Place it on a stable surface or mount the tool to be tested.

Set parameters – Choose the torque measurement unit and direction (clockwise/counterclockwise).

Apply torque – Use the tool (screwdriver, wrench, motor shaft, etc.) on the meter.

Read value – The torque is displayed digitally in real time.

Record/store – Save or note the result if needed.

Tips: How to choose the right digital torque tester?

- Measurement range: Ensure the portable torque tester's measurement range covers your commonly used torque values.

- Accuracy requirements: Select the appropriate accuracy level based on your application.

- Compatible tool types: Confirm whether the torque tester is compatible with your torque tool types, such as manual wrenches and power tools.

- Functional requirements: For example, whether the torque measuring tools require data logging, USB connectivity, dual display, and other features.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.