The electrical cable fault detector, with its diverse functions including cable fault location, effectively helps power cable engineers and cable workers solve various cable-related problems and ensure the safe and stable operation of cable systems.

Precise Positioning and Anti-Interference Technology

- The cable fault locator, combined with an A-frame, specifically locates ground faults in directly buried cables. Its two probes or coils accurately receive the step voltage signal transmitted by the transmitter, adapting to various working environments and helping personnel quickly pinpoint the fault location.

- Multi-filter technology suppresses power frequency and harmonic interference, ensuring signal stability. In fault location mode (direct connection), the transmitter supports four frequency outputs: 640Hz, 1280Hz, 2.56kHz, and 3.20kHz, allowing flexible selection based on site conditions to enhance locating accuracy.

- Calibrating current direction eliminates interference from adjacent cables and prevents tracking errors. This feature effectively mitigates interference from adjacent cables, improving the accuracy of cable path detection. Operators can monitor the intensity of signal interference in real time based on the color changes of the simulated line, allowing them to adjust detection strategies and enhance detection effectiveness.

Highly Secure Design

- A 360°all-round pipeline path indicator continuously displays depth, current, and relative pipeline position. The simple and intuitive interface allows for easy operation without prior experience. This mode provides comprehensive cable path information, enabling operators to clearly understand cable direction, depth, and current conditions, making it easy for even inexperienced operators to use.

- The transmitter features fully automatic overload and short-circuit protection. Operation must be performed by authorized personnel only, and access to live cables is strictly prohibited. The A-frame uses an aviation socket for connection, interchangeable accessories, and is compatible with standalone handles. The receiver features a 4.3-inch touchscreen for intuitive operation, lowering the barrier to entry.

- The transmitter is powered by an 11.1V 12800mAh lithium battery with an adjustable 10W output power and a maximum voltage of 150Vpp, along with a 5.6-inch touchscreen display. The receiver uses a 7.4V 6400mAh lithium battery and a 4.3-inch touchscreen. Both devices comply with IEC safety regulations and have excellent voltage resistance, making them suitable for outdoor use.

Applications

The cable fault locator is suitable for multiple scenarios: troubleshooting high and low voltage cable faults in the power industry, testing communication cables in the communications industry, troubleshooting production cables in industrial enterprises, locating indoor cable problems in the civil construction field, and can also be used for cable fault detection in special environments such as ships, rail transit, mines and oil fields.

Railway

Shopping Mall

Industrial Park

Communications

| Model | SISCO-CFL-KL9600APRO |

| Receiver | |

| Power Supply | 7.4V DC 3400mAh rechargeable Li-ion battery pack |

| Receiving Configuration | Built-in receiving coil; Rogowski coil;Stethoscope(Remote Antenna) |

| Bluetooth Communication | Bluetooth communication |

| Connecting to mobile apps for various data processing | |

| Receiving Frequency | Active detection frequency:577Hz、640Hz、1280Hz、2.56kHz、3.20kHz、4.09kHz、8.19kHz、10kHz、33kHz、66kHz、82kHz、201kHz |

| Passive detection frequency:50Hz、250Hz3.20kHz、4.09kHz、8.19kHz、10kHz、33kHz、66kHz、82kHz、201kHz | |

| Locating Mode | Broad Peak Mode, Peak Response Mode, Null Mode |

| Classic Mode | |

| Plan View Mode | |

| Locating Mode and Screen | Signal Curve Mode |

| Depth Measurement Accuracy | ±5%(depth below 3m) |

| ±10%(depth from 3m to 20m) | |

| Target Cable Direction Identification | During the cable route locating, the pinpoint arrow points to the target cable under test. |

| Sound Indication | FM: Sound pitch changes with signal strength |

| Anti-interference Ability | The extremely narrow receiving frequency band can fully suppress power frequency and harmonic interference from adjacent running cables and pipelines. |

| LCD | 3.5-inch color screen LCD |

| Dimensions | 290mm×128mm×700mm |

| Weight | 1.9kg |

| Transmitter | |

| Power Supply | 11.1V DC 12800mAh Rechargeable lithium-ion battery pack |

| Direct Connection; | |

| Locating Method | Signal Coupling; |

| Induction; | |

| Output Frequency | 577Hz,640Hz,1280Hz,2.56kHz,3.20kHz,4.09kHz,8.19kHz,10kHz,33kHz,66kHz,82kHz,201kHz |

| Output Power | 10W max,10 power gears available |

| Impedance | Fully automatic real-time impedance matching and protection functions |

| Output Voltage for Direct Connection | 150V max |

| Circuit Protection | Overload and short-circuit protection |

| LCD | 5.6-inch LCD color screen |

| Charger | DC 12.6V 2A |

| Dimension of Transmitter | 320mm×275mm×145mm |

| Weight | Transmitter 3.85kg; |

| Transmitting Clamp 1.18kg | |

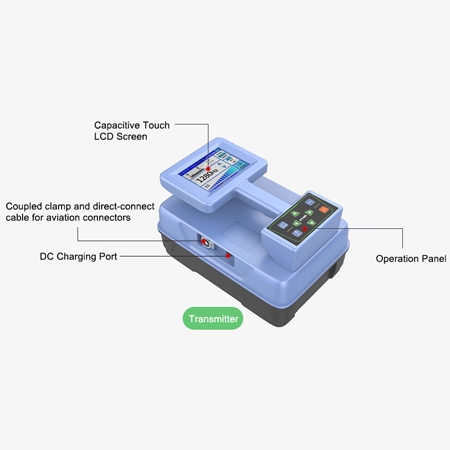

Structure Diagram

Q1: How to Use a Cable Fault Locator?

A1: To use a cable fault locator, connect the instrument to the faulty cable, select a test mode (such as low-voltage pulse or high-voltage flashover), transmit a signal, analyze the reflected waveform, determine the distance to the fault, and then precisely locate the fault along the cable. After repair, retest to confirm the location.

Q2: How Does a Cable Fault Locator Work?

A2: Cable fault locators typically use technologies such as time domain reflectometry (TDR), bridge technology, and acoustic-magnetic synchronization. They are portable, easy to use, and offer high locating accuracy. They are widely used in cable maintenance and emergency repair in industries such as power, communications, railways, and petrochemicals, significantly improving troubleshooting efficiency and reducing power outage time and repair costs.

Q3: What Factors Affect the Test Accuracy of a Cable Fault Locator?

A3: The test accuracy of a cable fault locator is affected by a variety of factors, including cable length, type, installation environment, and connector quality; the instrument's sampling rate, pulse width, signal processing capabilities, operator experience, external electromagnetic interference, grounding conditions, and fault type (such as low-resistance, high-resistance, flashover, or broken wire). These factors together determine the accuracy and reliability of fault location.

Tips: How to Maintain a Cable Fault Locator Daily?

For daily maintenance, regularly wipe the device body and test ports with a dry, soft cloth to prevent dust and water accumulation that may affect contact. Store the device in a dry, well-ventilated environment free from excessive vibration, away from direct sunlight, high temperatures, and humidity. If not used for extended periods, charge the device regularly (or remove the battery) as instructed to prevent damage from battery drain. Gently plug and unplug test cables and RJ45 connectors during use to prevent wear and deformation of the ports. Also, avoid physical damage such as dropping or impacting the device to ensure test accuracy and longevity.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.