The portable radiation detector features a built-in Geiger–Müller sensor housed behind side ventilation openings, ensuring fast response and stable detection performance. Its single-button control design simplifies operation, making it suitable for beginners and professionals alike. With its portable size, durable housing, and clear alert modes, this Geiger counter radiation detector is an essential tool for personal protection and environmental monitoring.

Automatic Day/Night Display Mode

- Automatic Day/Night Display Mode: The detector intelligently switches between bright day mode and low-glare night mode according to ambient light conditions. This ensures clear visibility whether you are conducting inspections outdoors under strong sunlight or checking radiation levels in dim indoor environments.

- Adaptive Backlight Adjustment: The screen brightness adjusts in real time to prevent reflections in daylight and reduce eye strain in the dark, providing a comfortable and accurate reading experience in any lighting situation.

- Enhanced Readability in All Environments: With its high-contrast interface and adaptive display, the detector maintains excellent readability during fieldwork, emergency response, or nighttime monitoring tasks.

- Energy-Efficient Display Control: The automatic brightness system helps reduce unnecessary power consumption, extending battery life during long outdoor operations or extended monitoring sessions.

One-Button Power-On, Easy to Use

- One-Button Power-On: Designed for quick use, the detector turns on instantly with a single button press, making radiation checks fast and effortless.

- Simple and User-Friendly Operation: The intuitive control layout allows beginners and professionals to operate the device easily without complex setup steps.

- Quick Start for Immediate Measurement: The detector begins reading radiation levels within seconds after powering on, ideal for rapid inspections and on-the-go safety checks.

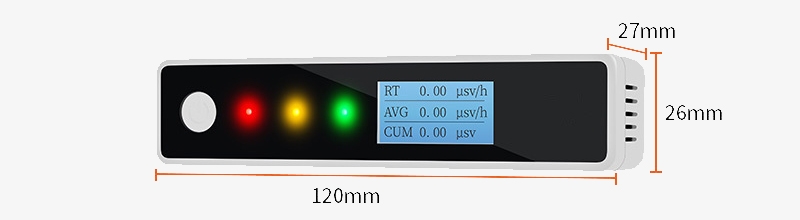

Dimension

Applications

SISCO radiation detector is a device used to detect and measure ionizing radiation, such as alpha, beta, gamma rays, and neutrons. Radiation detectors are used in medical imaging, industrial safety, environmental monitoring, and security to measure ionizing radiation. They help ensure safe radiation levels, detect contamination, and prevent the unauthorized transport of radioactive materials. They’re also crucial in scientific research for studying radiation effects.

Environmental

Security

Industrial

Medical

| Model | SISCO-RD-HZ-550 |

| Sensor Type | Energy-compensated GM tube |

| Measurable Type | β-rays, γ-rays, X-rays |

| Energy Range | 20keV~3.0keV≤±30% (137Cs-) |

| Sensitivity | 80cpm/μSv/(Co-60) |

| Resolution | 0.01μSV/h |

| Measurement Range | 9999μSV/h |

| Real-time Error | ≤3% |

| Power Supply | 5V/USB 3.7V lithium battery/500 mAh |

| Charging Time | 1~2 hours |

| Dimensions | 187*92*60mm |

| Weight | 420g |

Q1: What is a radiation detector?

A1: A radiation detector is a device designed to detect and measure ionizing radiation, such as alpha, beta, gamma rays, and neutrons. These detectors work by sensing the interaction of radiation with matter, often producing an electrical signal that correlates with the intensity or type of radiation present. Radiation detectors come in various types, including Geiger-Müller counters, scintillation detectors, and solid-state detectors, each tailored to detect different forms of radiation or provide varying levels of sensitivity.

Q2: Do radiation detectors need calibration?

A2: Yes, radiation detectors need regular calibration to ensure accurate and reliable measurements. Calibration involves adjusting the detector to account for any changes in its performance over time, which can be caused by factors such as aging components, environmental conditions, or variations in detector sensitivity. Regular calibration helps maintain the accuracy of the readings and ensures that the detector provides precise data for assessing radiation levels. Calibration is typically performed using known radiation sources and may be required by regulatory standards to ensure compliance and safety.

Q3: Can radiation detectors detect non-ionizing radiation?

A3: Most radiation detectors are designed to detect ionizing radiation, such as alpha, beta, gamma rays, and neutrons. Non-ionizing radiation, which includes radio waves, microwaves, infrared, and visible light, requires different types of sensors. For example:

- Radio frequency (RF) meters and electromagnetic field (EMF) meters are used to measure non-ionizing radiation like radio waves and microwaves.

- Photodetectors (such as photodiodes) measure visible light, while infrared sensors detect infrared radiation.

Tips: Do Geiger counters need calibration?

Yes. Geiger counters require regular calibration to maintain accurate and reliable measurements. Over time, the sensitivity of the Geiger-Müller tube and the device’s internal electronics can drift due to aging, environmental conditions, or frequent use. Calibration involves comparing the detector’s response to a certified radiation source and adjusting the instrument to match known standards.

Most manufacturers recommend calibrating the device every 12 months, though units used in industrial, laboratory, medical, or regulatory environments may require more frequent checks. Regular calibration ensures the Geiger counter continues to deliver trustworthy readings, supports compliance with safety guidelines, and helps users confidently assess radiation levels in critical applications.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.