A laser level operates by emitting a beam of laser light and features a highly accurate horizontal measuring device. It can be utilized to determine the verticality of surfaces such as floors, walls, or reference planes. Serving as an instrument for measuring and controlling the horizontal plane, it finds extensive applications in various scenarios including construction, decoration, interior design, bridge construction, precision positioning of CNC machine tools, wall tiling, leveling measurements, mechanical manufacturing, and more. In this article, sisco will introduce how does the laser level work, to help you have a better understanding of it.

Working Principle of Laser Level

A laser level is an instrument used to detect horizontal planes. It utilizes laser technology to generate a horizontal line, determining the levelness of a surface by observing the position of light rays. The principle of a laser level is based on the laws of light propagation and geometric principles. It consists of a device that emits laser beams and another device that receives laser beams.

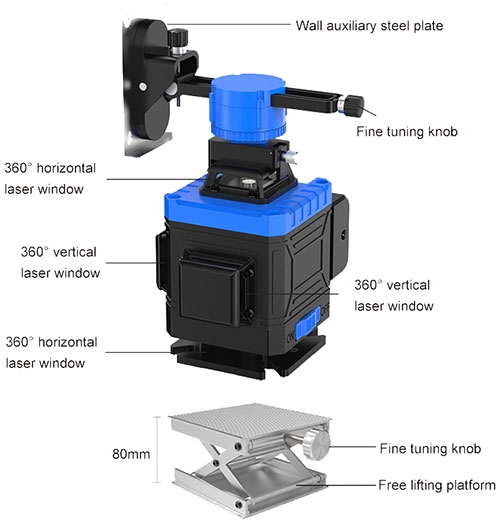

The emitting device typically includes a laser emitter and a rotating mirror. The laser emitter generates a collimated laser beam, which is then emitted horizontally by the rotation of the mirror. The rotation speed of the mirror is usually very fast, reaching several hundred revolutions per minute.

The receiving device comprises a receiver and a detector. The receiver receives the beam emitted by the laser emitter and reflects it back to the detector. The detector can perceive the position of the beam, thus determining the position of the horizontal line. Common detectors include bubble tubes and photodiodes.

When the laser level is in operation, the rotating mirror continuously rotates, causing the laser beam to trace a straight line at a certain frequency on the horizontal plane. The receiver captures the beam and reflects it back to the detector. Based on the position of the received beam, the detector emits a signal reflecting the position of the horizontal line.

By observing the signals from the detector, operators can deter

mine the levelness of the plane. If the signal on the detector remains stable at a relatively fixed position, the plane is level; if the signal fluctuates up and down, it indicates an uneven plane. Operators can adjust the position of the plane to stabilize the signal on the detector, achieving a level effect.

Applications of Laser Level

- Measuring Horizontal Dimensions of Objects

The laser level is a technology that accurately measures the horizontal dimensions of objects. It offers high accuracy and rapid measurement advantages over traditional manual methods, significantly improving construction quality by providing precise data. It adopts new technology for quick and accurate measurements, enhancing work efficiency, and reducing measurement workload, making construction projects easier and more efficient. - Measuring Angles of Objects

The laser level is not only used for measuring horizontal dimensions but also for measuring verticality, rotation, projection, and angles. It has the capability to position and orient laser beams for accurate measurements under different circumstances, meeting specific accuracy requirements, and achieving high-precision measurement results.

In summary, the laser level utilizes laser technology and geometric principles to determine the levelness of surfaces by emitting laser beams and observing changes in light positions. It offers advantages of high accuracy and rapid measurement and finds extensive applications in construction engineering, civil engineering, and other fields.