Lower price melt flow indexer applies controlled heat and pressure to quantify how much material flows over a set period. The melt flow rate tester widely used in plastic production, plastic products, petrochemical industry and related colleges and universities.

Equipped with High-Resolution Color LCD Display

- High-resolution color LCD display provides real-time visualization of test temperature, load status, timing process, and measurement results for clear and intuitive operation.

- Real-time data and process monitoring, allowing users to observe the melt flow testing process and system stability directly on the screen.

- Visualized automatic testing workflow, with clear status indicators, step-by-step operation prompts, and completion notifications displayed on the color screen.

- Multi-parameter simultaneous display, enabling temperature, load, cutting cycles, and MFR/MVR results to be viewed at a glance, improving testing efficiency.

- User-friendly graphical interface, supporting quick parameter setup and menu navigation, reducing operator errors.

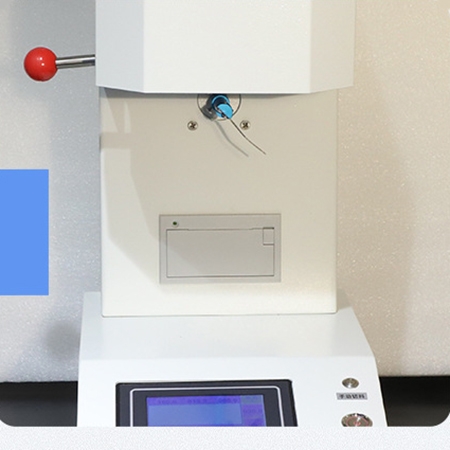

Built-In Micro Thermal Printer

- Built-in micro thermal printer enables instant printing of test results directly after measurement, eliminating the need for external printing devices.

- Automatic test report output, including key parameters such as test temperature, load, test method, and MFR/MVR results, ensuring complete and traceable records.

- One-touch printing function, allowing users to quickly generate hard-copy reports for quality control documentation and audits.

- Compact and integrated design, with the printer seamlessly built into the instrument, saving workspace and improving laboratory efficiency.

- Supports continuous printing, making it suitable for high-frequency testing in production quality control environments.

Applications

SISCO melt flow indexer is mainly used in the plastics and polymer industry to measure the melt flow properties of thermoplastic materials. It is widely applied in plastic manufacturing, raw material quality control, polymer R&D laboratories, injection molding and extrusion processing plants, and plastic recycling industries to ensure material consistency, processing stability, and product quality.

Plastic Recycling Industry

Plastic Recycling Industry

Polymer R&D Laboratory

Polymer R&D Laboratory

Injection Molding

Injection Molding

Plastic Manufacturing

Plastic Manufacturing

| Model | SISCO-MFI-DR-601A |

| Standard Die Diameter | Ø2.095 ± 0.005 mm |

| Standard Die Length | 8.000 ± 0.025 mm |

| Half Die Diameter | Ø1.050 ± 0.002 mm |

| Half Die Length | 4.000 ± 0.015 mm |

| Charging Barrel Inner Diameter | Ø9.550 ± 0.025 mm |

| Charging Barrel Length | 152 ± 0.1 mm |

| Piston Rod Diameter | Ø9.475 ± 0.015 mm |

| Piston Rod Length | 6.350 ± 0.100 mm |

| Standard Test Loads | 8 sets of standard weights |

| Relative Error of Weights | ≤ 0.5% |

| Temperature Range | Ambient to 450 °C (500 °C optional) |

| Temperature Stability Accuracy | ±0.5 °C |

| Display Resolution | 0.1 °C |

| Cutting Method | Manual or automatic cutting (optional) |

| Printing Function | Built-in micro printer with automatic print output |

| Power Supply | AC 220V ±10%, 50 Hz |

| Dimension | 250*350*600 mm |

| Weight | 60kg |

Q1: What does a melt flow indexer measure?

A1: A melt flow indexer measures the Melt Flow Index (MFI), also known as Melt Mass-Flow Rate (MFR), which indicates how easily a thermoplastic material flows when melted under a specified temperature and load. The result reflects the material's viscosity and molecular weight consistency, and is commonly expressed in grams per 10 minutes (g/10 min) according to standard test methods such as ASTM D1238 and ISO 1133.

Q2: Why is melt flow indexer important?

A2: A melt flow indexer is important because it provides a quick and reliable indication of a plastic material's flow behavior, which directly affects processing and product quality. By measuring the Melt Flow Index, manufacturers can control raw material quality, ensure batch-to-batch consistency, select suitable materials for injection molding or extrusion, detect material degradation, and maintain stable production processes, all in accordance with standards such as ASTM D1238 and ISO 1133.

Q3: What materials can be tested with a melt flow indexer?

A3: A melt flow indexer can be used to test thermoplastic materials that soften and flow when heated. Common test materials include polyethylene (PE), polypropylene (PP), polystyrene (PS), ABS, polyethylene terephthalate (PET), nylon (PA), and polycarbonate (PC), as well as other engineering plastics and recycled polymers used in injection molding, extrusion, and blow molding processes.

Tips: What materials can be tested with a melt flow rate tester?

A melt flow rate tester can be used to test a wide range of thermoplastic materials that melt and flow under controlled temperature and load conditions. Typical materials include polyethylene (PE), polypropylene (PP), polystyrene (PS), ABS, polyethylene terephthalate (PET), polyamide (PA/nylon), and polycarbonate (PC).

It is also suitable for evaluating engineering plastics, modified polymers with additives or fillers, and recycled plastics, helping manufacturers assess material quality, flow consistency, and processing suitability for injection molding, extrusion, and blow molding applications.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.