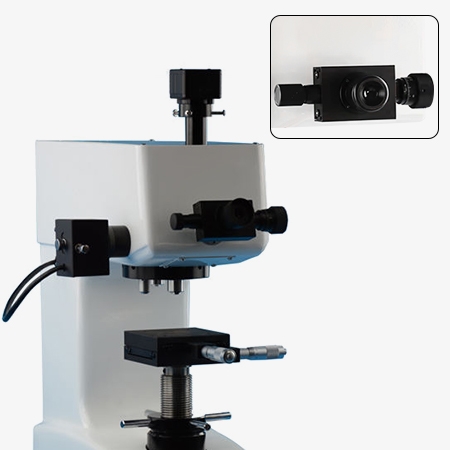

A micro Vickers hardness tester is a precision instrument used to measure the hardness of small, thin, or delicate materials such as metals, ceramics, coatings, and microstructures. The light source adopts a high-definition imaging illumination system, ensuring a uniform and clear light field for accurate observation. This kind of hardness tester widely used in metallurgical laboratories, research institutions, and quality control departments to analyze material properties, heat treatment effects, and surface hardness gradients.

Micro Vickers Hardness Tester with Multifunctional Operation Panel

- Micro Vickers hardness tester with a multifunctional operation panel, operators can easily input and adjust settings through soft-key interface, minimizing human error. This precision is crucial when testing thin coatings, micro-components.

- The intuitive design of the multifunctional panel reduces operator training requirements. Clear icons, menus, and prompts guide users through each testing step. By centralizing all test functions and data visualization on one control panel, operators spend less time on manual adjustments and calculations.

10X High-definition Eyepiece

- The high-definition eyepiece provides clear, sharp, and bright images of the indentation made by the diamond indenter. In micro Vickers testing, the diagonal length of the indentation is extremely small—often only a few micrometers—so image clarity is critical for accurate measurement.

- The combination of a 10X eyepiece and 100X objective results in an overall magnification of 1000X, which provides an excellent balance between clarity and measurement resolution, makes digital micro Vickers hardness tester well used for lab analysis.

Applications

SISCO's Vickers hardness tester is widely used in material testing and quality control due to its versatility and precision. Its primary application is in metallurgy, where it measures the hardness of metals and alloys. This helps determine material properties such as strength, wear resistance, and durability, which are critical in manufacturing and engineering processes.

Ceramic

Metal Parts

Wafer

Glass

| Model | SISCO-HT-HV-1000Z |

| Test Force | 10gf (0.098N), 5gf (0.245N), 50gf (0.49N), 100gf (0.98N), 200gf (1.96N), 300gf (2.94N), 500gf (4.9N), 1kgf (9.8N) |

| Conversion Scale | HRA, HRB, HRC, HRD, HRF, HV, HK, HBW, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T |

| Microscope | 100X (observation), 400X (measuring) |

| Minimum Measurement Unit | 0.031μm |

| Measuring Range | 5~3000HV |

| Test Force Application Method | Automatic (load/ hold/ unload) |

| Test Force Holding Time | 0~60s |

| X/Y Test Bench | Size: 100*100mm, Max. travel: 25*25mm |

| Data Output | LCD digital display |

| Maximum Height of Specimen | 80mm |

| Distance From Indenter Center to Outer Wall | 95mm |

| Power Supply | AC 220V 50Hz/ 110V 60Hz |

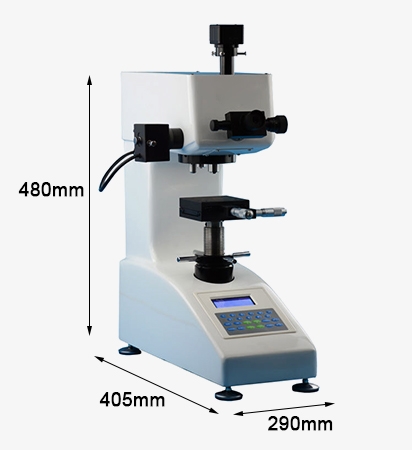

| Dimension | 405*290*480mm |

| Weight | About 40kg |

| Basic Configuration | Host machine*1, micro Vickers indenter*1, weight*6, weight rod*1, X-Y stage*1, thin sheet*1, flat vice table*1, level gauge*1 , micro Vickers hardness test block (high test block*1, low test block*1), objective (10X*1, 40X*1), screwdriver*2, horizontal adjustment screw*4, power cord*1, 10X eyepiece*1, spare fuse (2A)*2, dust cover*1 |

| Optional Configuration |

Host machine+eyepiece; Host machine+eyepiece+regular software (including USB camera+USB cord+encryption dongle) for Win7; Host machine+eyepiece+version A software (including USB camera+USB cord+encryption dongle) for Win10 |

Dimension:

Q1: What is the working principle of the Vickers hardness tester?

A1: The Vickers hardness tester measures a material's hardness by pressing a diamond-shaped pyramidal indenter (with a square base and 136° angles) into the specimen under a specific load. The load is applied slowly and held for a fixed dwell time, after which it is removed. The size of the resulting indentation is measured under a microscope, specifically the two diagonals of the square impression. The Vickers hardness (HV) is calculated using the applied load divided by the surface area of the indentation.

Q2: How to maintain the Vickers hardness tester?

A2: To maintain a Vickers hardness tester, regularly clean the indenter, stage, and lenses with a soft, lint-free cloth to prevent dust buildup. Inspect the indenter for damage or wear and replace it if necessary. Keep the tester in a stable, vibration-free environment with controlled temperature and humidity. Avoid excessive force when handling samples, and cover the instrument when not in use to protect it from dust and contaminants.

Q3: Are there any safety concerns when operating the Vickers hardness tester?

A3: Yes, there are safety concerns when operating a Vickers hardness tester. The main risks involve handling the sharp diamond indenter, which can cause puncture injuries if mishandled. Applying excessive force during testing may damage the specimen or the machine, posing potential hazards. Eye protection is essential when observing the indentation under a microscope to prevent injury from debris or reflections.

Tips: Why is the micro Vickers method suitable for thin coatings and small parts?

The micro Vickers hardness test is particularly suitable for thin coatings and small parts due to its ability to measure hardness on a very small scale with high precision. Its optical measurement system can precisely determine the diagonals of these tiny indentations, providing reliable hardness values. This makes it ideal for applications where component size or coating thickness is limited, such as in microelectronics, surface-treated metals, or precision-engineered small parts.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.