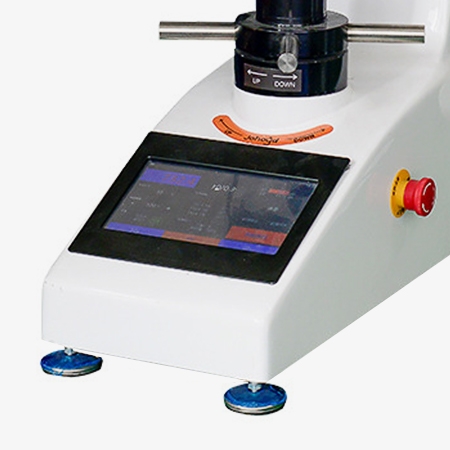

A touch screen digital Vickers hardness tester is a modern precision instrument used to measure the hardness of materials such as metals and ceramics. Turret can automatically switch between the eyepiece and the indenter, avoiding instrument damage caused by manual errors and greatly improving efficiency. The digital touch screen interface makes operation more intuitive and efficient compared to traditional models.

Vickers Hardness Tester with Touch Screen

- Intuitive Operation and User Experience. The touch screen interface simplifies the entire testing process. Users can easily adjust settings, and view results directly on the display without navigating through complex buttons or menus.

- High Precision and Repeatability. Digital control systems ensure consistent loading and dwell times, minimizing human error and improving the accuracy of hardness measurements.

Adopts Cast Aluminum Housing

- Lightweight yet Strong Construction. Cast aluminum provides an ideal balance between strength and weight. Despite its low weight, cast aluminum is highly resistant to mechanical stress, ensuring the frame maintains its shape and alignment even after years of use.

- Enhanced Vibration Damping and Measurement Accuracy. Cast aluminum helps absorb minor vibrations and mechanical noise from the environment. This damping effect reduces interference during the indentation process, improving the repeatability and accuracy of hardness measurements.

- Corrosion Resistance and Durability. Aluminum naturally forms a thin oxide layer on its surface that protects it from corrosion. A Vickers hardness tester with a cast aluminum housing is therefore more resistant to environmental factors such as moisture, chemicals, and temperature fluctuations.

Applications

SISCO's Vickers hardness tester is widely used in material testing and quality control due to its versatility and precision. Its primary application is in metallurgy, where it measures the hardness of metals and alloys. This helps determine material properties such as strength, wear resistance, and durability, which are critical in manufacturing and engineering processes.

Ceramic

Metal Parts

Wafer

Glass

| Model | SISCO-HT-HVST-5Z | SISCO-HT-HVST-10Z |

| Vickers Hardness Scale | HV0.3, HV0.5, HV1.0, HV2.0, HV3.0, HV5.0 | HV0.3, HV0.5, HV1.0, HV3.0, HV5.0, HV10.0 |

| Test Force | 0.3Kgf, 0.5Kgf, 1.0Kgf, 2.0Kgf, 3.0Kgf, 5.0Kgf | 0.3Kgf, 0.5Kgf, 1.0Kgf, 3.0Kgf, 5.0Kgf, 10.0Kgf |

| Power Supply | AC 110V 60Hz/ 220V 50Hz | |

| Display | 5-digit hardness value, 4-digit diagonal length (D1, D2), hold time, number of tests, mean, standard deviation, return | |

| Load Control | Automatic (load/ hold/ unload) | |

| Test Force Holding Time | 1~99s | |

| Optical Channel | Dual optical channels (eyepiece and CCD channels) | |

| Optical System | Objective lens: 10X 20X; Eyepiece: 10X, Total magnification (μm): 100X, 200X; Measuring range (μm): 400; Resolution (μm): 0.125 | |

| Hardness Measuring Range | (5~3000)HV | |

| XY Test Bench | Size: 100×100mm; Travel range: 25×25mm; Minimum reading: 0.01mm | |

| Maximum Height of Specimen | 165mm | |

| Maximum Width of Specimen | 130mm (distance from indenter to machine) | |

| Data Output | USB cord; USB flash drive (optional) | |

| Dimesnion | 585*200*630mm | |

| Weight | 42kg | |

| Configuration | Host machine*1, weight*3, XY precision stage*1, flat vice table*1, horizontal adjustment screw*4, power cord*1, 10x eyepiece*1, Vickers hardness block*2, spare fuse(2A)*2 | |

Dimension:

Q1: What is the working principle of the Vickers hardness tester?

A1: The Vickers hardness tester measures a material's hardness by pressing a diamond-shaped pyramidal indenter (with a square base and 136° angles) into the specimen under a specific load. The load is applied slowly and held for a fixed dwell time, after which it is removed. The size of the resulting indentation is measured under a microscope, specifically the two diagonals of the square impression. The Vickers hardness (HV) is calculated using the applied load divided by the surface area of the indentation.

Q2: How to maintain the Vickers hardness tester?

A2: To maintain a Vickers hardness tester, regularly clean the indenter, stage, and lenses with a soft, lint-free cloth to prevent dust buildup. Inspect the indenter for damage or wear and replace it if necessary. Keep the tester in a stable, vibration-free environment with controlled temperature and humidity. Avoid excessive force when handling samples, and cover the instrument when not in use to protect it from dust and contaminants.

Q3: Are there any safety concerns when operating the Vickers hardness tester?

A3: Yes, there are safety concerns when operating a Vickers hardness tester. The main risks involve handling the sharp diamond indenter, which can cause puncture injuries if mishandled. Applying excessive force during testing may damage the specimen or the machine, posing potential hazards. Eye protection is essential when observing the indentation under a microscope to prevent injury from debris or reflections.

Tips: What are the advantages of using a touch screen digital Vickers hardness tester?

Its intuitive interface makes operation faster and easier, reducing training time and human error. The digital display ensures precise control of test parameters. Real-time data processing improves accuracy and repeatability. Users can store and analyze results conveniently. Overall, it enhances efficiency, accuracy, and user experience, making it ideal for quality control, research, and production environments.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.