The non penetrating inductive wood moisture meter instantly ready for use, delivering quick response times during measurements. It's an essential tool for contractors, woodworkers, and homeowners working on projects involving wood, drywall, and concrete.

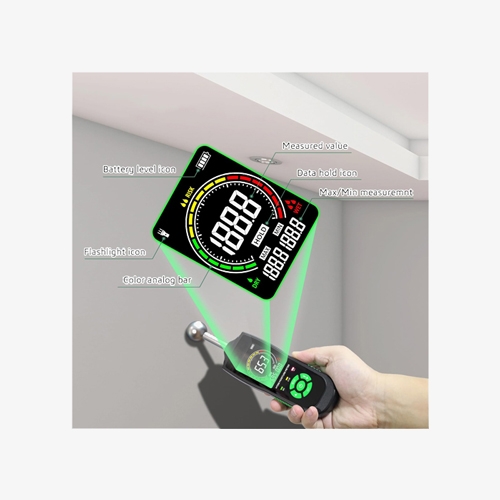

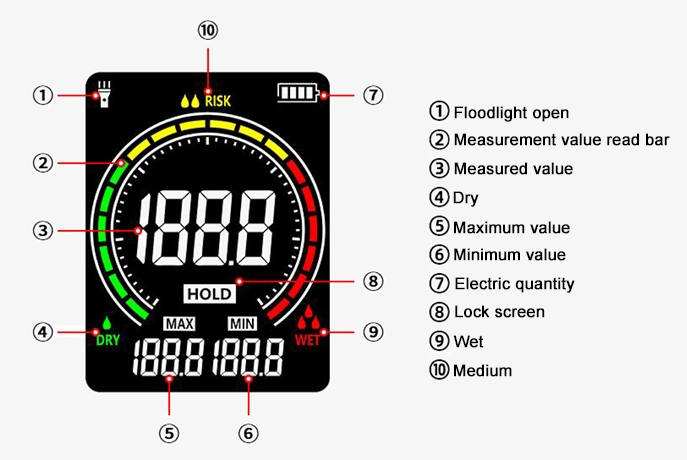

Enhanced Display and Calibration for Precise and Convenient Measurement

- User-Friendly Display: The high-definition backlit color screen makes data easy to read. The HOLD screen lock function ensures convenient reading of measured data.

- Convenient Calibration: Press the "MEAS" button at startup for automatic calibration. During calibration, keep the device at least 100mm away from any objects.

Precise Detection and Deep Measurement Non Invasive Moisture Meter

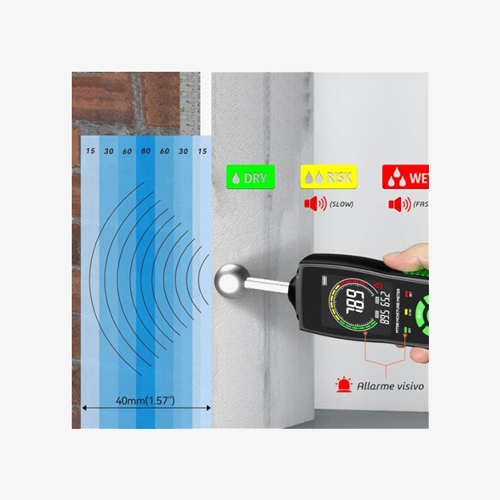

- Enhanced Sensitivity: The newly upgraded spherical sensor probe offers precise and sensitive detection.

- Deep Measurement Capability: Capable of measuring depths ranging from 5 to 40mm, allowing for easy detection of internal moisture.

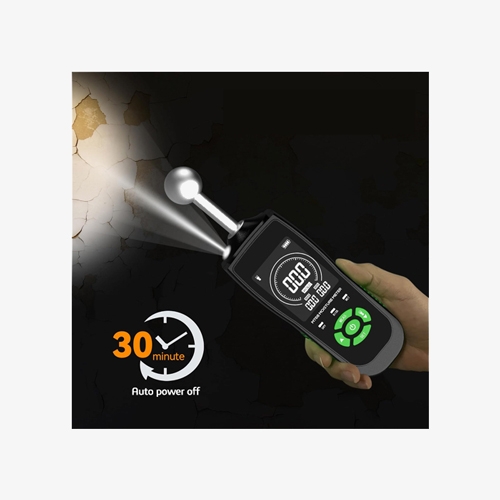

Automatic Power Off with Enhanced Low-Light Measurement Precision

- Automatic Shutdown: The non-invasive inductive moisture detector will automatically power off after 30 minutes of inactivity.

- Designed for Low-Light Conditions: Allows for accurate measurement in low-light or nighttime conditions, ensuring safer and more efficient use.

Applications

The SISCO non destructive wood moisture meter is a highly versatile tool, widely utilized across various applications. It's commonly employed in roof leak detection, where its sensitivity can pinpoint moisture hidden beneath the surface. Additionally, it excels in measuring moisture content in wood, making it an essential instrument for assessing the condition of wooden structures or materials. The portable moisture meter is also effective in detecting moisture in brick walls, helping to identify potential issues that could compromise structural integrity. Moreover, it's frequently used to measure moisture levels in wooden flooring, ensuring that conditions are optimal before installation or during maintenance.

Wood Moisture

Wall Moisture

Wood Floor Moisture

Roof Leaks

| Model | SISCO-MM-MT68 |

| Measuring Depth | 5~40mm |

| Measurement Range | 00.0~100.0 |

| Measurement Accuracy | ±2.5% (at 25℃) |

| Probe Length | 58mm |

| Display | 2.4-inch color LCD display |

| Alarm | Indicator light and buzzer alarm |

| Auto-Shutdown | 30 minutes of inactivity |

| Power | 3 AAA batteries (not including) |

| Operating Temperature | 0~45°C |

| Operating Humidity | 0~75% |

| Storage Temperature | -20~70°C |

| Size | 202*55*26mm |

| Weight | 165g |

Readings and Moisture Content Conversion

| Display | Gypsum (pepper quality) moisture content (CM%) | Water mud base material moisture content (CM%) | Wood moisture content (CM%) |

| 15 | / | / | / |

| 20 | / | / | 10.00 |

| 25 | / | / | 12.00 |

| 30 | 0.25 | / | 15.00 |

| 35 | 0.30 | 2.50 | 17.00 |

| 40 | 0.40 | 2.65 | 20.00 |

| 45 | 0.65 | 2.85 | 23.00 |

| 50 | 1.00 | 3.20 | 25.00 |

| 55 | 1.40 | 3.55 | / |

| 60 | 1.70 | 4.00 | / |

| 65 | 1.90 | 4.30 | / |

| 70 | 2.05 | 4.70 | / |

| 75 | 2.20 | 5.10 | / |

| 80 | 2.35 | 5.45 | / |

| 85 | 2.50 | 5.75 | / |

| 90 | 2.65 | 6.10 | / |

※The reading of the instrument is a unitless value of 0-100, which is different from the CM% (calcium carbide method) moisture content. Users can convert the instrument reading and CM% moisture content based on the data in this table (for reference only and not binding).

Details

Dimension (mm)

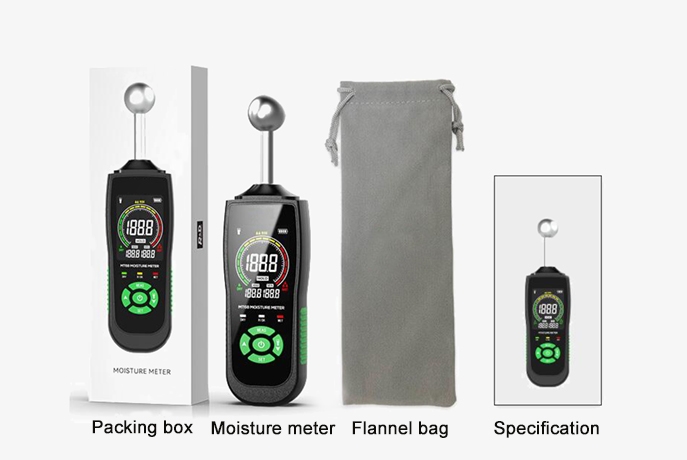

Packing List

- 1 x Moisture meter

- 1 x Packing box

- 1 x User manual

- 1 x Packing bag

Q1: What is a healthy moisture level?

A1: A healthy moisture level for wood typically ranges between 6% and 8% for indoor environments, such as in furniture, flooring, and other interior applications. This range helps prevent issues like warping, cracking, and mold growth. For outdoor wood or wood in more humid environments, a moisture level of up to 12% can be considered normal, though it varies depending on the specific climate and type of wood. Maintaining wood within these moisture ranges is crucial for its durability and longevity.

Q2: What factors can affect the accuracy of a humidity meter?

A2: The accuracy of a humidity meter can be influenced by several factors, including the need for regular calibration to prevent sensor drift and ensure precise readings. Temperature variations can affect humidity measurements, especially if the meter lacks temperature compensation. The quality and type of the sensor also play a crucial role, with high-quality sensors generally providing more reliable data. Environmental factors like dust and pollutants, along with improper placement near heat sources or direct sunlight, can skew results. Additionally, slow response times, power supply issues, and exposure to electromagnetic interference can all compromise accuracy. Regular maintenance, including cleaning the sensor, is essential to maintain the meter's performance.

Q3: What is the difference between a spherical induction moisture meter and a traditional pin-type moisture meter?

A3: The spherical moisture sensor differs from traditional pin-type moisture meters in several key ways. The spherical sensor is non-invasive, meaning it does not need to penetrate the material to measure moisture, thereby preventing any potential damage to the surface being tested. In contrast, pin-type moisture meters require the insertion of pins into the material, which can leave small holes or cause minor surface damage. Additionally, spherical moisture sensors typically offer a broader measurement range and deeper detection capabilities, making them ideal for assessing moisture content in a variety of materials without causing harm.

Tips: How does a ball-type moisture meter work?

A spherical moisture meter works by using a non-invasive sensor that emits low-frequency electromagnetic waves into the material being tested. As these waves penetrate the material, they interact with its internal moisture content, causing changes in the material's capacitance. The meter detects these changes and converts them into a moisture reading, displayed on the device. Unlike traditional pin-type meters, the spherical sensor doesn't require physical penetration into the material, making it ideal for measuring moisture levels in sensitive surfaces without causing any damage. This technology allows for quick, accurate assessments of moisture in materials like wood, drywall, and concrete.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.