This microbial air sampler features an integrated portable design and is powered by a lithium battery, weighing only 1.6 kg, truly enabling convenient and on-the-go testing.

Anderson Impaction-Based Precision Sampling

- This air sampler in microbiology utilizes the Anderson impaction principle (Design level is 5), with a sampling flow rate of 100 liters per minute and an impact velocity of less than 12 m/s, ensuring effective collection of microbial particles larger than 1 micrometer. It is suitable for precise sampling of airborne microorganisms.

- It supports setting the sampling volume (1-9999L), sampling delay, and flow compensation functions, offering intuitive and flexible operation. It also features an audible alert function, with a buzzer indicating sampling completion.

- This microbial air monitoring equipment supports multiple disinfection methods. The instrument exterior and sampling head can be disinfected with commercial disinfectants or 70-90% alcohol solution (or isopropanol aqueous solution), effectively avoiding cross-contamination and ensuring the purity of the sampled data.

Easy Operation and Data Processing

- This microbiological air sampling equipment is compatible with Φ90×15mm universal petri dishes. Two sets of these dishes are included in the package, eliminating the need for additional consumables; it is ready to use out of the box.

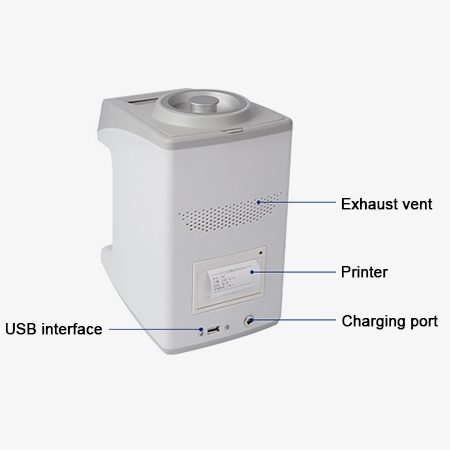

- Equipped with a touchscreen and a built-in printer, sampling records can be printed at any time. It also supports exporting historical data to a computer via USB, improving field work efficiency.

- This microbial air sampler can store over 500 sampling records for convenient subsequent analysis and research. When the storage is full, it automatically overwrites old records or allows manual data deletion, ensuring flexible data management.

Applications

Air samplers have a wide range of applications, which can be summarized into four main areas: In environmental monitoring, they are used to track air quality in cities and regions over a long period of time and assess the status of pollutants such as PM2.5 and ozone; in industrial safety, they monitor toxic and harmful gases and dust in working environments such as chemical plants and mines in real time to protect occupational health; in public health, they provide a basis for disease prevention and control and environmental sanitation; and in fire early warning systems, they enable early warning of fires to protect life and property.

Industrial Safety

Fire Early Warning

Public Health

Environmental Monitoring

| Model | SISCO-AS-LDKF |

| Sampling Flow Rate | 100L/min±5% |

| Sampling Orifice Impact Velocity | 17m/s |

| Sampling Port Flow Rate | 0.4m/s isokinetic sampling in a cleanroom |

| Setting Sampling Range | 0.01-9999L adjustable |

| Agar Petri Dish | Standard size: Φ90mm×15mm |

| Screen Size | 3.5-inch touchscreen |

| Data Communication Interface | USB port |

| Volume | Φ120mm×300mm |

| Weight | 1.6kg |

| Dimensions | 22cm×14cm×25cm |

| Power Supply | AC/DC dual-use, built-in 6000mAh high-capacity lithium battery, continuous sampling for 8 hours |

Structural Diagram

Q1: What are the Key Parameters of an Air Sampler?

A1: The core parameters of an air sampler include: sampling flow rate (including stability and accuracy, with constant/medium/low flow rates to suit different scenarios), sampling time (precisely settable and cumulatively timed), and compatibility with the sampling medium (compatible with filter membranes, adsorption tubes, etc.). In addition, flow rate calibration accuracy, negative pressure tolerance, operating temperature and humidity range, air path sealing, and the battery life of portable models and the continuous operation stability of stationary models directly affect sampling accuracy and applicable scenarios, making them key selection criteria.

Q2: What is the Correct Operating Procedure for an Air Sampler?

A2: Before the operation, check the air circuit sealing, battery/power supply status, and calibrate the flow rate. Install the appropriate filter membrane or adsorption tube as needed, ensuring a secure and leak-free installation. Set the sampling flow rate, time, and other parameters, and aim the sampling head at the target area (avoiding obstructions and strong airflow). After starting the device, observe its operating status. Avoid touching or moving the instrument during sampling. After sampling, promptly remove the collection medium and seal the label. Turn off the device, clean the sampling head and air circuit, and record the usage to ensure sample integrity and future device usability.

Q3: What Factors can interfere with the Use of Air Samplers?

A3: How often the probe of a dew point meter needs to be cleaned depends on a variety of factors, including the environment in which it is used, the frequency of use, the cleanliness of the sample gas, and the specific requirements of the instrument. Here are the steps to clean the probe. Air samplers are susceptible to interference from multiple factors: Environmentally, high temperature, high humidity, and strong airflow can affect sampling stability; dust or corrosive gases may clog the air path and damage components. Operationally, flow calibration deviations, improper installation of the sampling medium, and obstruction or improper positioning of the sampling head can lead to sample distortion. Equipment-wise, air path leaks, pump aging, sensor drift, and insufficient battery life (for portable models) can reduce sampling accuracy. Furthermore, unreasonable sampling time settings and ambient electromagnetic interference can also interfere with normal operation and data accuracy.

Tips: How to Perform an Active Air Sampler?

Active air sampler methods mainly include two types: impaction sampling and filtration sampling. An impaction sampler uses high-speed airflow to impact airborne microbial particles onto the sampling medium. Depending on the particle size, single-stage or multi-stage impactors can be used for graded collection. Filtration sampling, on the other hand, passes air through a specific filter material, trapping microbial particles on the filter. Selecting appropriate sampling methods and equipment, and adjusting sampling parameters such as sampling flow rate and sampling time according to actual conditions, can effectively improve sampling efficiency and the accuracy of results.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.