This low cost rotational viscometer ensures stable performance even under varying conditions, providing accurate data for quality control. It is widely applied in the food industry for testing edible oils, sauces, and dairy products, as well as in industrial processes involving lubricants, chemicals, and pulp materials.

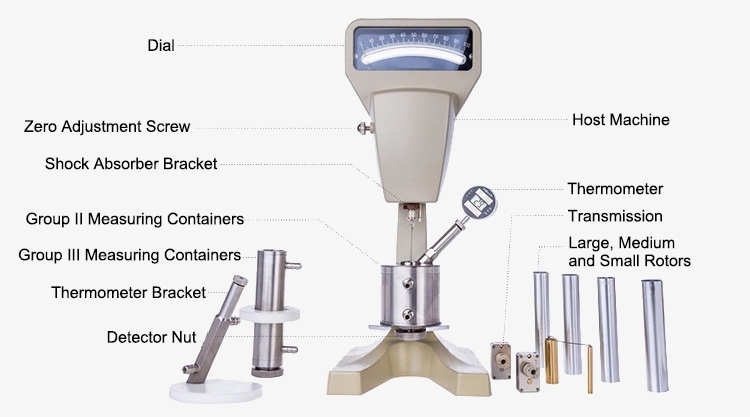

- Arc-shaped Dial Design : Allows direct data reading without conversion, making operation more convenient.

- Wide Measuring Range: Rotational viscometer offers a wide measuring range from 1 to 1,000,000 mPa·s to cover various applications.

- Stable Drive System: Powered by a miniature synchronous motor, ensuring constant speed rotation unaffected by load or voltage fluctuations.

- Digital Thermometer Equipped: The viscosity testing equipment is equipped with a digital thermometer that displays temperature in real time for better test condition control.

- Optional Gear Reducers: SISICO rotational viscometer supports optional 10× and 100× gear reducers to suit different measurement requirements.

- Portable Design: Lightweight and handheld for easy operation in various environments.

- High Accuracy: Rotational viscometer provides reliable measurement results with ±5% FS accuracy.

- Durable Construction: Compact structure with long-term stability for laboratory and industrial use.

Applications

SISCO rotational viscometer is widely used in the manufacturing, scientific research institutes or laboratory for viscosity measurement of oils, greases, paints, coatings, pulp, textiles, food, pharmaceuticals, adhesives and cosmetics, etc.

Adhesives

Pulp

Food

Pharmaceuticals

| Model | SISCO-VISCO-NDJ79 |

| Measuring Range | 1 ~ 1,000,000 mPa·s |

| Rotational Speed | 750, 75, 7.5 rpm |

| Measuring Accuracy | ±5% FS |

| Gear Ratio Units | 1:1, 1:10, 1:100 (with reducer: 1:10, 1:100) |

| Rotor Configuration | Unit set includes rotors 1×0.1, 1×0.2, 1×0.4, 1×0.5 |

| Package Dimensions | 185x165x450 mm |

| Weight | 15 kg |

Details

Q1: What is a viscometer?

A1: A viscometer is an instrument used to measure the viscosity of fluids (liquids and gases). Viscosity is a physical quantity that indicates the internal friction within the fluid when the fluid is flowing. It is the ability of the fluid to resist deformation. It is an important indicator used to identify some finished or semi-finished products. Viscosity varies from fluid to fluid and varies with temperature. There are mainly three types of capillary viscometers, rotational viscometers and falling ball viscometers.

Q2: What is the definition of viscosity?

A2: When a liquid is flowing, the property of internal friction between its molecules is called the viscosity of the liquid. The viscosity of the liquid is expressed by viscosity, which is a resistance factor used to characterize the properties of the liquid. The viscosity of insulating oil is the same as the viscosity of general liquid, that is, the internal friction of the liquid, that is, when the insulating oil moves relative to laminar flow under the action of external force. The properties of insulating oil molecules that generate internal frictional resistance. The greater the internal friction of the insulating oil, the greater the viscosity, the more difficult the flow, and the poorer heat dissipation performance.

Q3: What is a viscometer used for?

A3: Viscosity is an important physical parameter used to measure the ability of liquids to resist flow. Using a viscometer to measure the viscosity of a liquid is an important means of industrial process control, improving product quality, and saving and developing energy. It is closely related to the fields of petroleum, chemical, electric power, metallurgy and national defense. Status plays an important role.

Tips: What is the measuring range of this rotational viscometer?

The rotational viscometer has a wide measuring range of 1~1,000,000 mPa·s, allowing it to accurately measure liquids of varying viscosities. This makes it suitable for a variety of applications, including industrial fluids, edible oils, dairy products, lubricants, and other food or chemical liquids, providing reliable and consistent results for both laboratory and on-site testing.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.