The provided 500mm digital vernier height gauge is a measuring device used to provide very precise height measurements. It comes with the error of ±0.05mm, a resolution of 0.01mm, and voltage of 1.5V. Digital height gauges have been the preferred precision measurement tool because of their ease of use and variety of functionality. These tools can work with other devices for more accurate performance.

Large screen digital display design

- LCD high-definition LCD screen, the numbers are clear and easy to read

- Comfortable in hand and full of functions

Precise fine-tuning device

- Toggle mechanism for more precise values

- High-definition scale film, dual display in metric and imperial

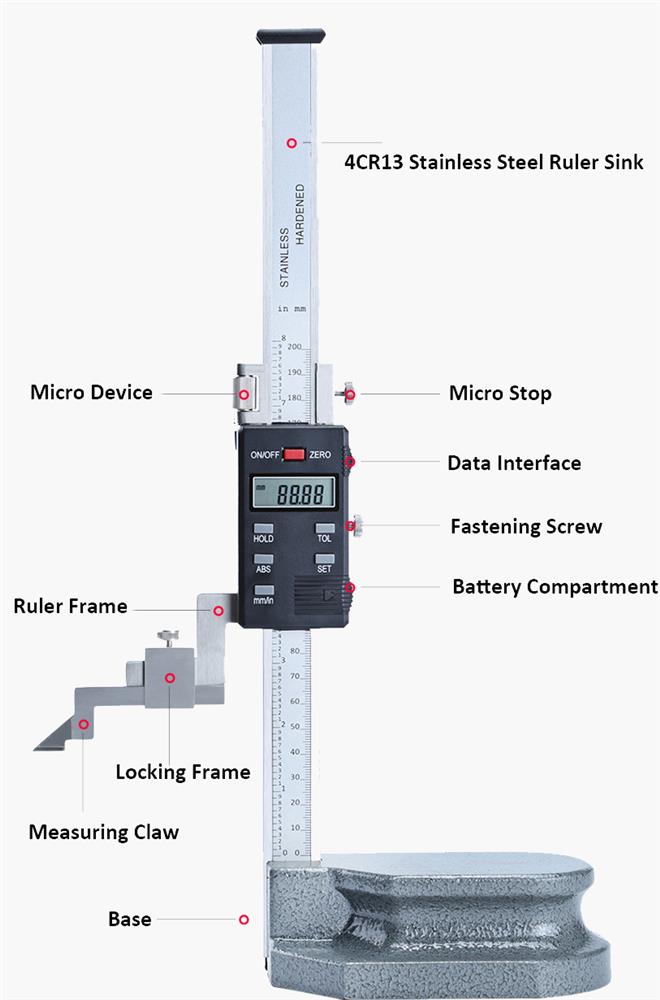

Detail

Applications

SISCO digital height gauges are also called height gauges. As the name suggests, its main purpose is to measure the height of workpieces, and it is also often used to measure shape and position tolerances, and sometimes to mark lines. Digital height gauges are mainly used in the automotive industry, manufacturing, science, and research industries.

- Model: SISCO-DHG-500

- Range: 0-500mm

- Voltage: 1.5V

- Resolution: 0.01mm

- Error: ±0.05mm

- Responding Speed: 1 m/s

- Body Material: 4CR13 stainless steel

- Battery Type: LR44 button-type

- Weight: 26kg

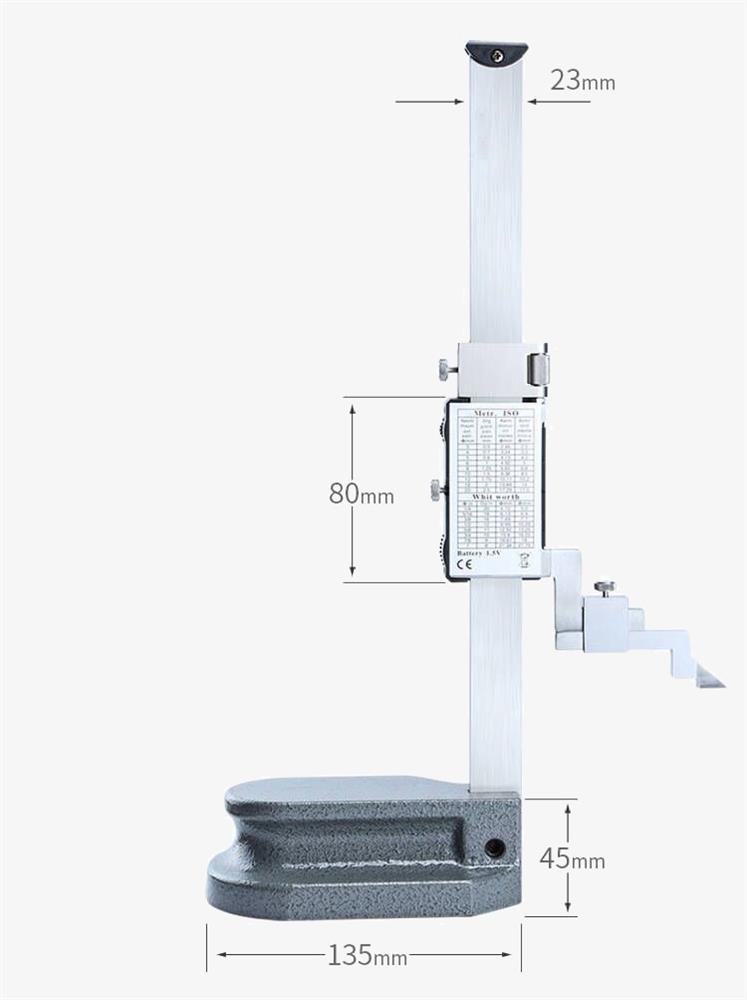

Dimension

Q1: What is a digital height gauge?

A1: A height gauge is one of the most used accuracy and precision tools in different industries. Some of these industries are manufacturing, automobile, metalworking, and healthcare. Typically, they’re used in production stages, such as in cutting and marking raw materials. In some cases, height gauges are utilized in quality control to check if products have met particular standards.

Q2: Is the digital height gauge accurate?

A2: Standard height gauges provide readings accurate to one-hundredth of an inch, but precision-engineered digital height gauges can determine accurate measurements up to the thousandth of an inch and beyond.

Q3: Why do we use digital height gauges?

A3: A digital height gauge is used for measuring the height of objects. Vernier height gauges are used in metrology and metalworking to detect or measure vertical distances. The height gauges are often used to measure a granite surface or scribe part features from a datum plane.

Tips: How to take the measurements of digital height gauge?

The actual measuring process can be started once the cleaning and preparation are done. Here are the steps to do it correctly:

- The surface of working the platform usually becomes the point of measurement. Make the platform surface and the measuring jaw gently touch with a measuring force of about three to five Newton. Also, make sure that the LCD shows a value of zero. To make it zero, press the ON/OFF/ZERO button.

- Adjust the movable jaw to its nearest inch or centimeter by holding the rod against the surface plate.

- Check the large LCD screen to get the reading.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.