Cheap price self-leveling laser level with 5 green laser lines, 360° rotating base, self-leveling green rotating laser is IP54 rated, which means that it’s protected against dust and water, providing a longer product life.

Waterproof design

- Fully enclosed lens design, waterproof, dropproof and dustproof.

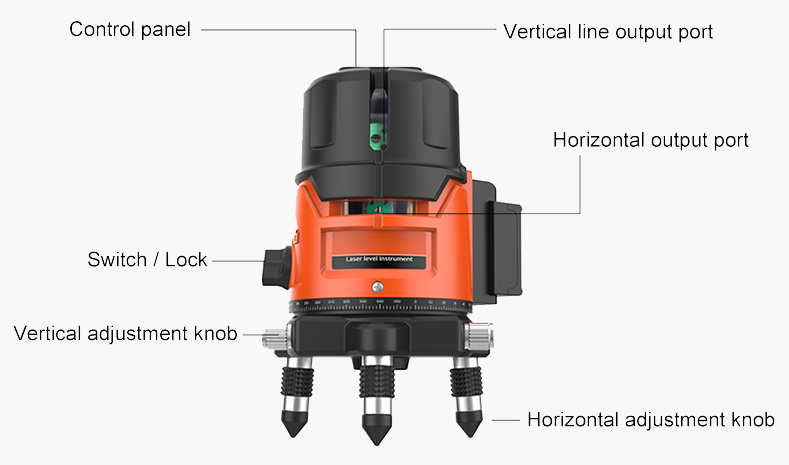

- Aluminum alloy thickened chassis, the body can be leveled by adjusting the tripod knob.

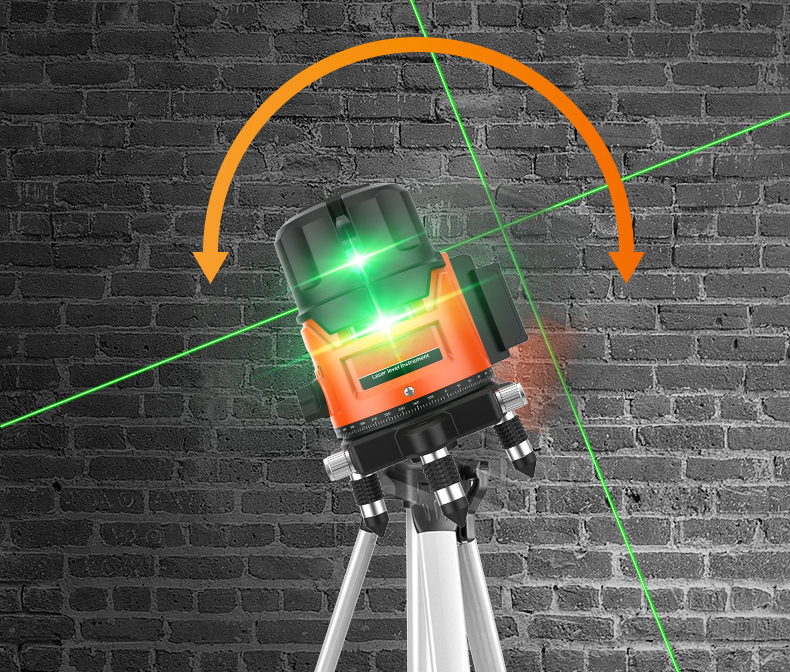

180° slash design

- With a tripod and adapter, you can hit the level line to the ground/ceiling.

- Magnetic damping technology and non-leveling alarm system to improve leveling accuracy.

- Precise positioning of vertical lines, reducing errors and improving efficiency.

Details

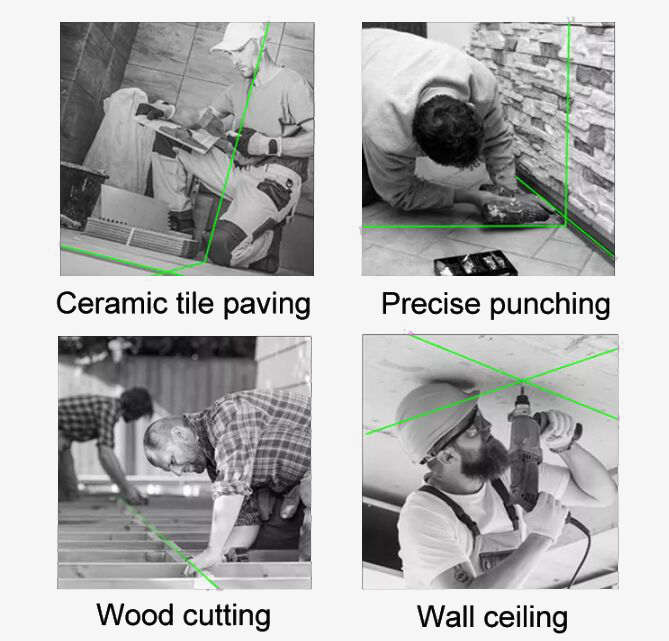

Application

SISCO high-intensity laser level is a common measuring tool for measuring angles. The high-precision green light level can be widely used in metallurgical steel plate cutting, stone cutting, wood cutting, machine vision and other fields.

| Model | SISCO-SL-05 |

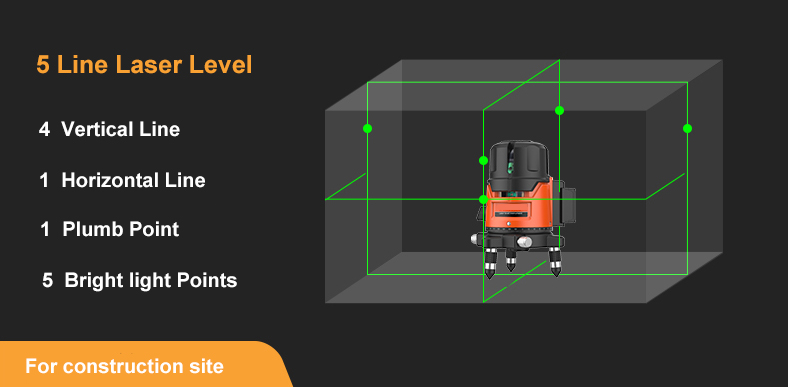

| No.of Laser Lines | 5 |

| Leveling Type | 4 vertical line, 1 horizontal line, 1 plumb dot, 5 bright dots |

| Laser Wavelength | 635nm |

| Self-Leveling Range | ±3° |

| Launch Angle | ≥120° |

| Horizontal Accuracy | 5m±1mm |

| Vertical Accuracy | 5m±1mm |

| Plumb Dot Accuracy | ±1mm at 1.5m |

| Line Width | 2mm |

| Line Color | Emerald green |

| Power Supply | 3 x AA batteries or AC power |

| IP Rating | IP 54 |

| Operation Temperature | 0℃~40℃ |

| Battery Type | Digital LCD rechargeable lithium battery (8 hours standby) |

| Function Key | Fingerprint touch buttons |

| Laser Head | Made in Germany |

| Laser Tube Life | 10 years |

| Outdoor Visible Distance | About 15m |

| Indoor Visible Distance | About 15m~40m |

| Weight | 2.5kg |

5 Line Laser Level Diagram

Q1: Is a green laser level better than red?

A1: Yes. Green lasers are much more efficient and visible in areas of broad daylight and direct sunlight. They are also able to travel longer distances, which is why they are so popular on construction sites.

Q2: What are green laser levels used for?

A2: A green line laser level tool is a construction tool that uses a laser to detect the vertical position of the object. It's used for measuring distances and heights, as well as for aligning objects on different levels.

Q3: Why are laser levels green?

A3: Lasers emitted by the green diode provide a solid line that can be seen at a longer distance without requiring a detector. Clearer to see by the human eye than any other color and four times more visible than red. Green Laser Levels provide a great edge in interior jobs.

Tips: How to adjust the zero calibration of laser level?

- Put the spirit level on a flat plate (or machine tool guide rail) with a solid foundation, and after the bubbles are stable, take a reading at one end such as the left end, and set it to zero. Then turn the level meter 180 degrees, and still put it on the original position of the plate. After the bubble is stabilized, still read the A grid at the original end (left end), and the zero position error of the level meter is 1/2 of the A grid.

- If the zero error exceeds the allowable range, the level meter zero adjustment mechanism (adjustment screw or nut) needs to be adjusted to reduce the zero error to within the allowable value. For non-regulated adjustment screws, the nut must not be twisted at will. Before adjustment, the level meter works The surface and the plate must be wiped clean. After adjustment, the screws or nuts must be tightened).

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.