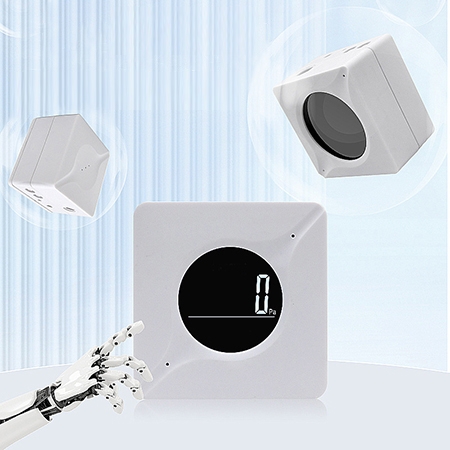

SISCO differential pressure transmitters utilize a high-precision differential pressure sensor and digital technology to accurately display real-time differential pressure, offering high accuracy and excellent long-term stability. This differential pressure transducer features a unique flush-mount installation method for easy installation, durability, and aesthetics. It is suitable for applications in cleanroom building automation, air conditioning equipment, and other fields.

Optional flush-mount installation for a secure and aesthetically pleasing appearance

- Flexible Installation Options: The differential pressure transmitter offers the convenience of optional embedded installation, allowing it to be securely mounted within control panels or equipment for a sleek and professional setup.

- Reliable and Secure Performance: With embedded installation, the transmitter is firmly integrated into the system, providing enhanced stability and reducing the risk of damage from external factors.

- Durable and Aesthetic Design: Designed to combine durability and visual appeal, the Differential Pressure Transmitter is built with high-quality materials that provide both robustness and an elegant look.

- Versatile Applications: The embedded installation option makes this transmitter suitable for a wide range of applications, from HVAC systems to chemical processing, where space efficiency and safety are crucial.

LCD display for clear and convenient reading

- Clear LCD Display for Easy Reading: The digital differential pressure transmitter is equipped with a high-resolution LCD display that provides clear and easy-to-read measurements of pressure values. Whether in dimly lit environments or high-speed operations, the large digital screen ensures accurate data is always visible and accessible, reducing the chances of misreading.

- User-Friendly Interface: With its intuitive LCD interface, users can quickly interpret data without the need for additional tools or complex settings. The display shows real-time pressure measurements, clearly labeled and easy to interpret.

- Practical and Convenient for Daily Operations: This differential pressure gauge’s LCD screen allows for quick and straightforward monitoring of pressure readings in real-time, enhancing workflow efficiency.

Applications

SISCO differential pressure gauge is essential in various industries for monitoring filter conditions, measuring flow rates, determining liquid levels in tanks, ensuring pump efficiency, maintaining clean room pressure, assessing HVAC system performance, and safeguarding hydraulic, boiler, and environmental systems, as well as in specialized applications like pharmaceutical factories, purified air conditioners, microelectronics environments, and blower pressure measurements, all by accurately measuring the pressure difference between two points to ensure optimal operation, safety, and compliance with regulations.

Purify Air Conditioner

Microelectronics

Blower Pressure Measurement

Pharmaceutical Factory

| Model | SISCO-DPG-WLC |

| Pressure Range | (-4 to 4) kPa |

| Mounting Type | Flush mount/end mount |

| Output Methods | No output/4-20 mA/0-10V/relay switch alarm |

| Overload Capacity | 1, 2, 3, or 4 depending on range: overload 5xFS, burst Pressure 10xFS |

| Accuracy | ±1% FS |

| Long-Term Stability | 0.2% FS/year |

| Power Supply | DC 24V |

| Operating Temperature | -20°C to 80°C |

| Operating Humidity | <80% RH |

| Connection | Hose Connector |

| Power Consumption | 0.5W |

| Display | Five-digit LCD or no display |

| Measured Media | Air, non-corrosive gases |

| Casing Material | PC/ABS |

| IP Rating | IP54 |

| Weight | 200g |

Q1: Can a differential pressure gauge measure both positive and negative pressure differences?

A1: Yes, a differential pressure gauge can measure both positive and negative pressure differences between two points. It is designed to indicate the difference regardless of which side has the higher pressure.

Q2: Can a differential pressure gauge be used in high-temperature environments?

A2: It depends on the specific gauge and its construction materials. Some diff pressure gauges are designed to withstand high temperatures, but it is important to check the manufacturer's specifications to ensure suitability for high-temperature applications.

Q3: Can I calibrate a differential pressure gauge myself?

A3: Yes, you can calibrate a differential pressure gauge if you have the proper equipment and follow the correct procedures. Calibration should be done using a known reference standard, and the process may vary depending on the gauge type. For critical applications, professional calibration services are recommended.

Tips: Can the differential pressure transmitter be used for both gases and liquids?

Yes, a differential pressure transmitter can be used for both gases and liquids, as long as it is selected according to the specific requirements of the medium being measured. The transmitter is designed to measure the pressure difference between two points in a system, whether it's a gas, liquid, or a slurry. However, it's important to ensure that the sensor material and diaphragm design are compatible with the characteristics of the medium, such as viscosity, corrosiveness, or temperature.

For optimal performance, choose a transmitter with appropriate seals and materials to handle the specific properties of gases or liquids in your system.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.