A digital liquid density meter is a instrument designed to measure the density of liquids quickly and accurately. In addition to measuring liquid density, this density meter can also determine liquid concentration. This dual functionality makes it versatile for applications in food and beverage production, chemical processing, environmental testing, and quality control.

Adopts Touch Screen

- Intuitive Operation. The touch screen interface simplifies the operation by allowing users to input commands, set parameters, and navigate menus directly on the screen. This eliminates the need for complex buttons or manual adjustments, reducing the learning curve for new users.

- Real-Time Data Display. Density meter with a touch screen, measurement results are displayed in real time, along with relevant parameters like temperature and measurement units. This immediate feedback helps users make timely decisions during experiments or quality control processes.

- It can Measure Two Parameters. This instrument can measure the density and concentration of liquid medium. Density range 0~2g/ml, concentration range 0~100% (20℃).

Stainless Steel Connector & Packing in Box

- Portability and On-Site Testing. Store in a box for easy portability. Lightweight and easy to carry, allowing measurements directly on the production line. Particularly useful for large-scale packaging facilities where materials are handled in multiple locations.

- High Durability and Longevity. Compared with plastic or aluminum connector, stainless steel is more robust and less prone to deformation, cracking, or aging. This significantly extends the service life of this liquid density meter and reduces maintenance and replacement costs over time.

Applications

SISCO density meter is widely used in the chemical, food, petroleum, and pharmaceutical industries for accurate measurement and quality control. Density meter provides reliable data for process monitoring, product consistency, and research applications across these fields.

Food

Petroleum

Pharmaceutical

Chemical

| Model | SISCO-DM-800B |

| Power Supply | built-in 3.7VDC lithium battery with charger |

| Density Range | 0~2g/ml, can be calibrated to a certain range according to usage conditions |

| Density Accuracy | 0.003g/ml; resolution: 0.0001; repeatability: 0.0005 |

| Concentration Range | 0~100%(20℃), can be calibrated to a certain range according to usage conditions |

| Concentration Accuracy | 0.5%; resolution: 0.1%; repeatability: 0.2% |

| Medium Temperature | 0~60℃ (liquid) |

| Ambient Temperature | -40℃~85℃ |

| Medium Viscosity | <2000mpa·s |

| Response Speed | 2s |

| Interface Material | Stainlless steel |

| Cable Material | Anti-corrosion silicone rubber |

| Wetted Parts | 316 stainless steel, special requirements available |

| Weight | About 5kg |

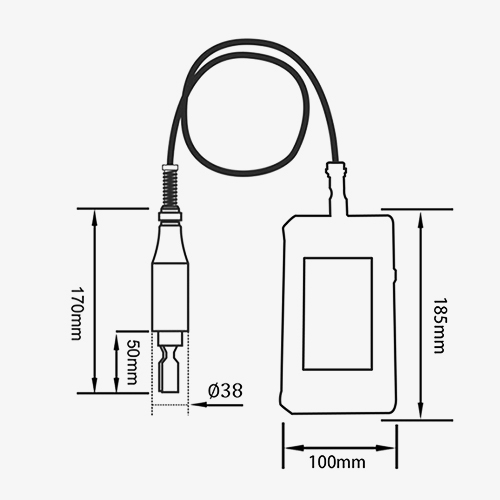

Dimension:

A1: What are the types of density meter?

Q1: A density meter is a scientific instrument used to measure the density of liquids/ gases, or sometimes solids by determining the relationship between mass and volume. In many models, a sample is placed in a measurement cell, and the device calculates density from changes in frequency, displacement, or pressure.

A2: What are the main applications of a liquid density meter?

Q2: A liquid density meter is widely used across industries to determine the density and concentration of liquids in real time. In the chemical and petrochemical sectors, it helps monitor product quality, blending ratios, and purity of fuels, solvents, and lubricants. In food and beverage production, it is applied to measure sugar content, alcohol strength, and consistency of syrups, juices, and dairy products. In pharmaceuticals, it supports formulation accuracy and batch control. Environmental and water treatment facilities use density meters to assess wastewater, brine, and solution strength.

A3: What factors affect the accuracy of a liquid density meter?

Q3: The accuracy of a liquid density meter is influenced by several key factors. Temperature plays a major role, as liquid density changes with temperature, making precise temperature control or compensation essential. Sample purity is also critical, since bubbles, particles, or impurities can distort measurements. Additionally, operator handling, sample preparation, and environmental conditions can impact results.

Tips: Precautions of using digital portable liquid density meter

- The product should be used in an environment where the temperature gradient changes as little as possible, and no shock or vibration is allowed to sensor during the operation.

- The measured medium is not allowed to freeze, otherwise it will damage the sensing element and cause damage to the density meter.

- Prevent dregs from settling in the tank.

- Hand it with care to prevent damage to the product.

- Do not drop the instrument directly.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.