An ESD wrist strap tester is a specialized device used to verify the effectiveness of an antistatic wrist strap, which protects sensitive electronic components from electrostatic discharge (ESD). If the resistance is too high or too low, the strap may not provide adequate protection. Regular testing of ESD wrist straps is part of industry standards and quality control procedures, ensuring continuous protection when handling delicate electronic devices and assemblies.

A Compact Wrist Strap Tester

- Portability and Convenience. A compact wrist strap tester is lightweight and small, making it easy to carry around. Users can conveniently move it between workstations and production lines. This mobility ensures that anti-static testing can be performed wherever it is needed, improving workflow efficiency in electronics manufacturing and laboratory environments.

- Space-Saving Design. The small footprint of a compact wrist band tester allows it to fit in tight workspaces or crowded electronics benches. It doesn’t occupy much room, which is particularly beneficial in laboratories or production lines where space is limited. Users can store it easily in drawers or toolkits without cluttering the workspace.

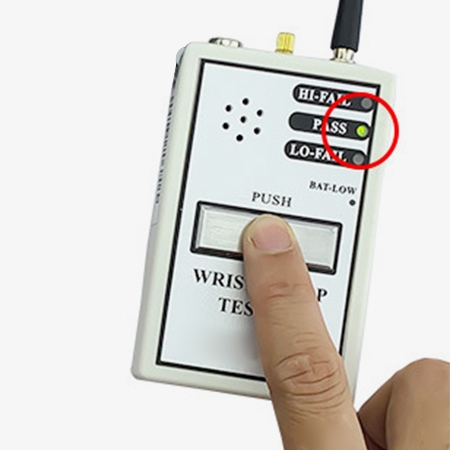

3 Indicator Lights

- Enhanced Safety. Electrostatic discharge (ESD) can damage sensitive electronic components or even pose hazards in certain industrial settings. The indicator lights ensure that any failure in the wrist strap is quickly noticed, allowing immediate corrective action. This visual alert reduces the chance of accidental damage or unsafe handling of sensitive equipment.

- Error Reduction. The clear indicator lights in the ESD wrist band tester minimizes human error. Operators are less likely to overlook a defective strap, because the light provides a straightforward pass/fail signal.

Applications

SISCO's wrist strap tester is an essential device for maintaining electrostatic discharge (ESD) safety in electronics manufacturing, laboratories, and cleanroom environments. Its primary function is to verify that wrist straps, which ground personnel, are functioning correctly to prevent static buildup that could damage sensitive electronic components. Wrist strap monitor is critical for ESD compliance, workplace safety, and product reliability in any environment handling sensitive electronic equipment.

Electronics Factory

Data Center

Dust-free Workshop

Laboratory

| Model | SISCO-PGT-181 |

| Test Voltage | Regulated 9 volts DC |

| Temperature Range | Operating: 10 ℃ to 40 ℃; storage: -15 ℃ to 60 ℃ |

| Relative Humidity | 0% to 90% (non-condensing) |

| Accuracy | ±5% |

| Power Supply | 9V battery |

| Dimension | 95*60*26mm |

| Weight | 145g |

Indicator Display:

| Indicator | Tested Resistance Range | Beeping |

| HI-FAIL (Red) | 9MΩ above | X |

| PASS (Green) | 800KΩ≤R≤9MΩ | √ |

| LO-FAIL (Red) | 800kΩ below | X |

Dimension:

Q1: What is a wrist strap tester?

A1: A wrist strap tester is a device used to check the effectiveness of an anti-static wrist strap, which is worn to safely discharge static electricity from a person to prevent damage to sensitive electronic components. The tester measures the electrical resistance of the strap and ensures it falls within a safe range.

Q2: Does the ESD wrist strap tester provide audible or visual alerts?

A2: Most wrist band testers provide both audible and visual alerts. Visual alerts typically include LEDs indicating pass or fail status, while the grounding system is safe, a buzzer will sound.

Q3: Are there any maintenance requirements for the wrist strap tester?

A3: Yes, wrist strap monitor requires regular maintenance to ensure accurate and reliable measurements. Clean the contact with a soft, dry cloth to prevent oxidation or dirt buildup that could affect result. Store the device in a dry, dust-free environment when not in use.

Tips: How to use this ESD wrist strap tester?

- While wearing the wrist strap, plug the banana plug end of the cord into the jack.

- Lightly press the metal touch button marked"PUSH" so that the unit activates.

- Lighting of the green"PASS" LED indicates that the wrist strap and ground cord assemblies are functioning properly.

- If either Red"LO-FAIL" or Red"HI-FAIL" lights, the wrist strap wearer should check the wrist strap assembly immediately.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.