The oil quality testing machine is equipped with a 316 food-grade stainless steel probe, ensuring safety and reliability, and features WiFi connectivity. This frying oil quality tester is suitable for rapid on-site testing in the catering industry and can also be used for precise laboratory analysis.

OLED LCD screen, food-grade stainless steel probe

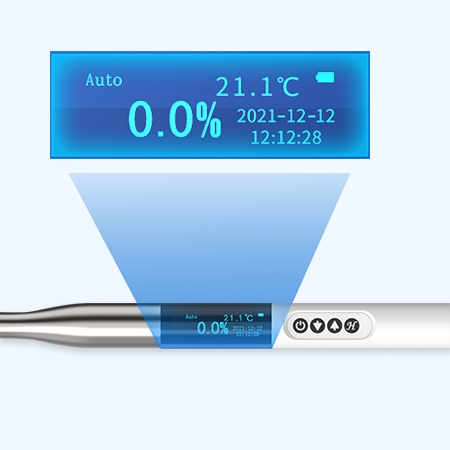

- This frying oil quality tester features a high-brightness OLED LCD screen with 5 levels of brightness adjustment, providing a clear and intuitive display. It has a built-in 900mAh lithium-ion rechargeable battery, supports Type-C fast charging, and is economical, environmentally friendly, and durable.

- The probe of the frying oil tester is made of 316 food-grade stainless steel, ensuring safety and reliability, and is suitable for direct contact with edible oil.

Results in 3 seconds, streamlined design

- This food oil quality tester provides results in just 3 seconds, helping users instantly grasp oil quality. With streamlined design and an IP67 waterproof rating, cooking oil quality tester is suitable for various complex environments such as kitchens.

- It supports TPM parameter calibration and upper/lower limit alarm value adjustment, ensuring accurate and reliable test results. The cooking oil check meter can upload data via WiFi, providing an intelligent solution for oil quality management.

Frying Oil Tester Structure

Application

This edible oil quality tester is suitable for the catering industry, canteens, frying plants, and food testing laboratories. It can quickly detect the total dissolved solids (%TPM) and temperature of edible oils.

Supermarket

Frying Industrial

Soft Films

Canteen

| Model | SISCO-OT-YT-SYP |

| Temperature Measurement | 0°C ~ 200°C |

| Measurement Resolution | ±0.1°C |

| Temperature Measurement Accuracy | ±1°C |

| TPM (Total Polar Compound Content) | 0~50% |

| TPM Measurement Accuracy | ±1.5% |

| TPM Resolution | 0.1% |

| TPM Sensor | Capacitive sensor |

| TPM Response Time | <3S |

| Temperature Sensor | PTC sensor |

| Battery Life | Continuous use time not less than 30 hours |

| Operating Temperature | 0~50°C |

| Storage Temperature | -40~70°C |

| Display Method | OLED high-brightness LCD screen, 5-level adjustable brightness |

| Housing Material | High-quality PC engineering plastic |

| Probe Material | 316 food-grade stainless steel |

| Weight (with probe protective cover) | 275g |

| Protection Rating | IP 67 |

| Detection Data | 10,000 records |

Q1: What is an frying oil tester?

A1: An frying oil tester is an instrument used to quickly assess the quality of edible oils. It primarily detects indicators such as total dissolved solids (%TPM), acid value, and peroxide value in oils to determine their suitability for continued use. It is widely used in the catering industry, canteens, frying plants, and food testing laboratories.

Q2: How does an frying oil quality tester work?

A2: Most oil tester machine use high-precision capacitive sensors to measure the total dissolved solids (%TPM) in the oil, judging its quality by changes in the oil's electrical properties. Simultaneously, a built-in temperature sensor monitors the oil temperature, and combined with algorithms, quickly outputs the test results. The oil quality testing machine can complete the measurement within seconds and display whether the oil exceeds the standard via an alarm or LCD screen.

Q3: How to use an frying oil quality tester?

A3: Simply insert or touch the probe of the frying oil quality tester directly into or to the oil, and wait a few seconds to read the value. The cooking oil check meter usually has a three-color alarm indicator; different colors indicate the oil's condition. After use, the probe can be cleaned with running water to ensure hygiene.

Tips: How to calibrate an frying oil quality tester?

The edible oil testing machine calibration is typically performed upon initial use or after prolonged use. Calibration requires the use of a standard oil sample or calibration solution provided by the manufacturer, following the instructions in the manual to correct the TPM parameters. Some digital oil tester support automatic calibration or software-assisted calibration, which can be completed via a cloud platform or host computer software, ensuring measurement accuracy and data reliability.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.