A handheld analog Webster hardness tester is a portable device used to measure the hardness of metals and other materials. The tester is compact, lightweight, and easy to use, making it ideal for field inspections or quality control in manufacturing. Its analog design provides immediate visual readings, and while less precise than digital versions, it offers reliable, practical measurements for everyday testing.

Webster Hardness Tester Equipped With Clear Scale

- The analog clear scale provides direct, real-time readings of the hardness value. Users do not need to perform extra calculations or convert measurements.

- A Webster hardness tester with an analog scale does not require batteries or electricity for the display, allowing it to be used in remote locations or harsh industrial environments where power sources may be limited.

Handheld and Easy to Use

- An easy-to-use Webster tester typically features a simple interface and clear markings, allowing even operators with minimal training to take accurate measurements. This reduces the learning curve and increases overall productivity in the workshop or laboratory.

- The combination of portability, quick testing, and non-destructive operation makes handheld Webster hardness testers perfect for field inspections.

- These testers are capable of measuring a variety of metals, including stainless steel, aluminum, and brass. Their ability to adapt to different materials makes them a versatile tool for multiple applications in engineering, automotive, aerospace, and maintenance industries.

Applications

SISCO's Webster hardness tester is primarily used for measuring the hardness of metals and metallic components in various industrial and laboratory settings. Its applications span multiple fields due to its simplicity, portability, and ability to provide quick hardness readings. In manufacturing and metalworking, it is used to test steel, brass, aluminum, and other alloys, ensuring that components meet required hardness specifications for durability and wear resistance.

Mechanical Manufacturing

Mold Treatment

Quality Test

Scientific Experiment

| Model | Suitable Material | Measuring Range | Sample Size | Cross Weight |

| SISCO-HT-W-20 | Aluminum alloy | 25~110 HRE, 58~131 HV | Thickness: 0.6~6; inner diameter>10 | About 1.5kg |

| SISCO-HT-W-20a | Thickness: 0.6~13; inner diameter>10 | |||

| SISCO-HT-W-20b | Thickness: 0.6~8; inner diameter>6 | |||

| SISCO-HT-W-B75 | Hard or semi-hard brass, ultra-hard aluminum alloy | 63~105 HRE | Thickness: 0.6~6; inner diameter>10 | |

| SISCO-HT-W-B75b | Thickness: 0.6~8; inner diameter>6 | |||

| SISCO-HT-W-BB75 | Soft brass, red copper | 18~100 HRE | Thickness: 0.6~6; inner diameter>10 | |

| SISCO-HT-W-BB75b | Thickness: 0.6~8; inner diameter>6 | |||

| SISCO-HT-W-B92 | Cold-roll steel sheet, stainless steel | 50~92 HRB | Thickness: 0.6~6; inner diameter>10 |

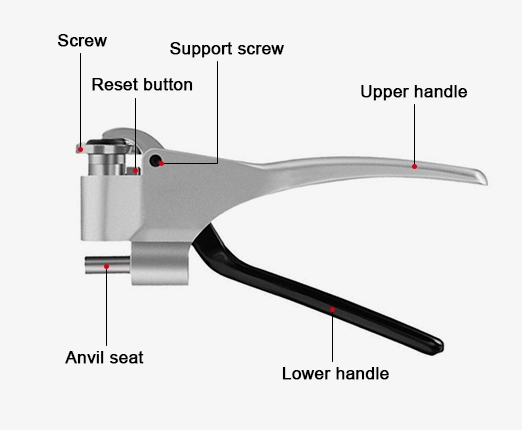

Structure:

Q1: What is a Webster hardness tester?

A1: The Webster hardness tester, also known as the Webster hardness clamp or Webber hardness tester, can be used for rapid testing of aluminum alloy hardness on the production site and is the preferred instrument for inspecting the mechanical properties of aluminum alloy profiles. It can also measure the hardness of brass and stainless steel. It is a handheld and efficient tool.

Q2: What material is a Webster hardness tester made of?

A2: The Webster tester is primarily made of aluminum alloy, which provides a strong yet lightweight structure, making it easy to handle and durable for long-term use. Aluminum alloy ensures resistance to corrosion and wear, maintaining the instrument's accuracy and reliability over time. Its lightweight nature allows for convenient portability in laboratory or field environments, while still providing a stable frame for precise hardness measurements.

Q3: Are there any safety precautions to follow when using the Webster hardness tester?

A3: Safety precautions are important when using a Webster hardness tester. Always ensure the tester is placed on a stable, flat surface to prevent slipping or inaccurate readings. Wear safety glasses to protect your eyes from any material fragments that might chip during testing. Keep hands and fingers clear of the impact area when operating the device. Regularly inspect the tester for wear or damage.

Tips: What is the correct way to hold the analog Webster hardness tester during measurement?

To correctly hold an analog Webster hardness tester, first ensure the test surface is clean and smooth. Hold the tester vertically. Keep the tester steady during the measurement to prevent tilting, which can cause inaccurate readings. Read the hardness value directly from the dial while maintaining this stable position for precise results.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.