The pH glass electrode is used for high-temperature, sterilized measurements. The dual liquid connection structure of the high-temperature-resistant gel and high-temperature-resistant solid dielectric allows the glass electrode to be sterilized directly at a temperature of 130 degrees Celsius.

Resistant to strong acid and alkali corrosion, online pH measurement

- sisco glass pH meter with sensitive glass bubbles and four layers of glass lamination.

- High-temperature resistant aerogel and solid dielectric liquid junction.

- The housing material is special glass, resistant to high temperatures and high pressures.

- High precision and repeatability.

- Accessories: Teflon sheath or stainless steel sheath. Increased acid and alkali resistance of the electrodes and easy installation.

- High-quality low-noise cable for 60m long-distance signal transmission.

Application

pH Electrode is widely used in the continuous testing and monitoring of pH, ORP, and temperature in thermal power, chemical fertilizer, metallurgy, environmental protection, pharmaceutical, biochemical, food, drinking water, etc.

| Model | SISCO-PHS-E710-K8S |

| Weight | 1kg |

| Measuring range | 0-14pH |

| Temperature range | -5℃-130℃ |

| Thermistor | Pt1000 |

| Compressive strength | 0.6MPa |

| Installation size | PG13.5 pipe thread |

| Shell material | Glass |

| Connection | Low noise cable directly led out/K8S |

| Cable length | Standard configuration 120mm (Customizable on demand) |

| Cable | Can be equipped with SK9 cable |

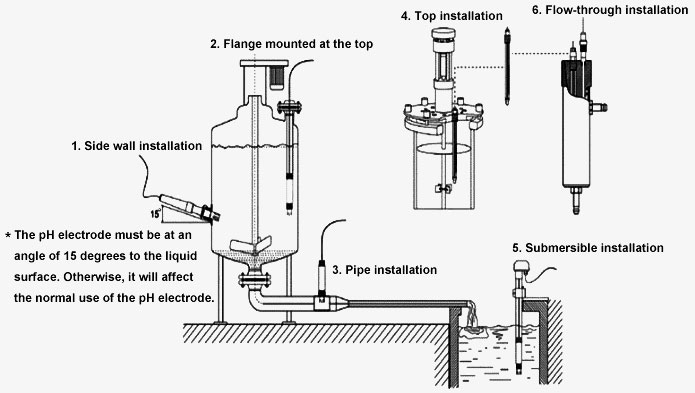

Installation

- Side wall installation (*The pH electrode must be at an angle of 15 degrees to the liquid surface. Otherwise, it will affect the normal use of the pH electrode.)

- The flange mounted at the top

- Pipe installation

- Top installation

- Submersible installation

- Flow-through installation

Q1: What is a pH electrode?

A1: The pH electrode is also called the pH probe pH sensor. The pH electrode is the part of the pH meter that is in contact with the substance to be measured and is used to measure the electrode potential.

Q2: Why do pH electrodes need to be soaked?

A2: The pH electrode must be soaked before use, because the pH bulb is a special glass membrane with a thin hydrated gel layer on the surface of the glass

membrane, which can only interact with the H+ ions in the solution under fully wet conditions. the response to. At the same time, after soaking the glass

electrode, the asymmetric potential can be greatly reduced and tend to be stable.

Q3: What is a reference electrode?

A3: An electrode with a known and constant electrode potential that does not respond to the activity of hydrogen ions in solution is called the reference electrode. Reference electrodes include mercurous sulfate electrodes, calomel electrodes, and silver/silver chloride electrodes. The most commonly used are calomel electrodes and silver/silver chloride electrodes. The role of the reference electrode in the measurement cell is to provide and maintain a fixed reference potential, so the requirements for the reference electrode are that the potential is stable and reproducible, the temperature coefficient is small, and the polarization potential is small when current flows.

Tips: What types of pH electrodes are there?

Liquid pH Electrode

The liquid electrode is a filled liquid electrode, which is the most typical, excellent quality, and most widely used electrode in the history of pH electrodes. Suitable for measurement of various industrial processes.

Gel pH Electrode

Gel electrodes are improved liquid electrodes. This electrode requires little maintenance and is suitable for demanding in-line measurements. It can still work for a long time after many times of CIP (cleaning in place) and SIP (steam sterilization).

Solid pH Electrode

Solid electrodes are widely used in the chemical industry. Features a new solid polymer reference electrolyte for extended life while maintaining accurate pH measurements for good performance even in the harshest industrial environments.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.